-

sandhyaprises@gmail.com -

View Mobile Number

| Business Type | Manufacturer, Exporter, Supplier |

| Size (Inches) | 4Inch, 33 |

| Color | Black |

| Usage | Oil Industry |

| Click to view more | |

Product Details

Material

Rubber

Country of Origin

India

Type

Rubber Seals

Brand Name

Mexico

Finishing

Polished

Port

MUMBAI

Payment Terms

L/C

Delivery Time

7 to 15 days

Packaging Details

Here are the **packaging details** for **PTFE Cladded Dam Rubber Seal**, a product typically used in **dams**, **hydropower plants**, and other water control structures to provide a **watertight seal** and prevent water leakage.

---

### **Packaging Details: PTFE Cladded Dam Rubber Seal**

---

### **Product Overview:**

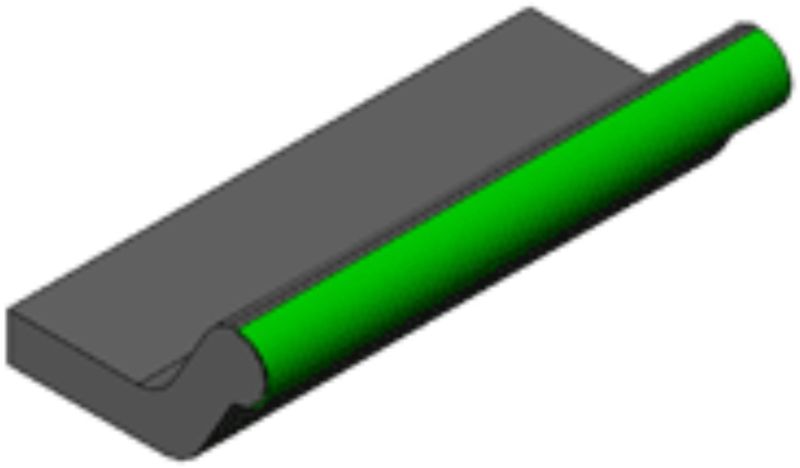

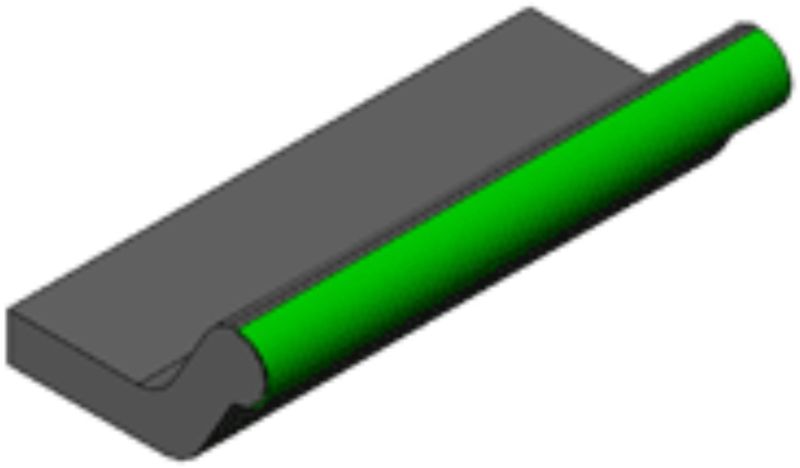

* **Product Name:** PTFE Cladded Dam Rubber Seal

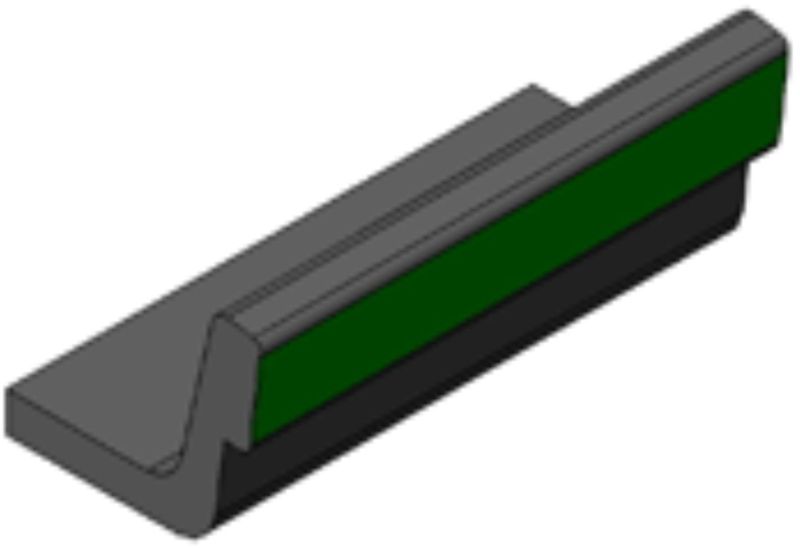

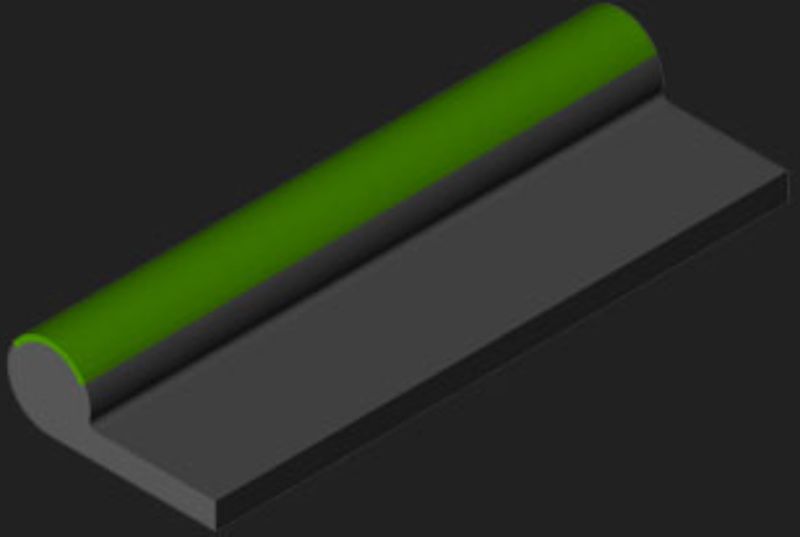

* **Material:** A composite material made from **rubber** and a **PTFE (Polytetrafluoroethylene) cladding** for enhanced durability and resistance to water, chemicals, and extreme temperatures.

* **Applications:** Primarily used in **dam gates**, **sluices**, and **hydraulic structures** to provide a long-lasting seal for water and fluid control. PTFE offers excellent resistance to wear and corrosion.

* **Sizes and Configurations:** Available in various sizes, depending on the specific design requirements of the dam or water control structure. Common sizes include **lengths** ranging from **1 meter to 10 meters** and **widths** up to **200 mm** or more.

---

### **Packaging Configuration:**

#### **1. Coiling or Rolling:**

* **PTFE Cladded Dam Rubber Seals** are typically **rolled or coiled** into **circular or cylindrical shapes** to prevent damage and maintain their integrity during transportation.

* The seals may be wrapped in **protective film** or **plastic wrap** to keep them free from dirt and moisture.

* If the seals are particularly long (e.g., **10 meters** or more), they are **coiled tightly** and secured with **cable ties** or **plastic bands** to maintain their shape.

#### **2. Protective Wrapping:**

* **Plastic Shrink-Wrapping**: The entire rolled or coiled rubber seal is typically **shrink-wrapped** or covered with a layer of **protective plastic** to shield it from dirt, moisture, and UV exposure.

* **Foam or Rubber Inserts**: In some cases, protective foam or rubber inserts may be used around the **edges** or **ends** of the seal to protect the PTFE cladding from physical damage during handling or transportation.

* **Corner Protection**: If the seal\'s packaging includes a **box** or **crate**, **foam corner protectors** may be applied to minimize risk of sharp impacts.

#### **3. Bundling for Larger Orders:**

* For larger orders, multiple rolls or coils of PTFE Cladded Rubber Seals may be **bundled together** using **strapping** or **reinforced plastic ties**.

* Each bundle is then **shrink-wrapped** to secure the items and prevent them from shifting during shipment.

#### **4. Crating (for International Shipments):**

* For **international shipments** or when additional protection is required, the rolled or coiled rubber seals are placed into **wooden crates** or **strong cardboard boxes**.

* The crates or boxes are sealed to protect the product from external environmental factors such as **humidity** or **physical handling damage**.

* **Fumigation** may be applied to the crates to meet **international shipping standards** (e.g., ISPM-15) if required.

---

### **Container Loading (Approximate):**

* **20-foot container:**

* Typically holds around **6-10 pallets**, depending on the size of each rolled seal and the packaging method.

* **Total weight**: \\~ **1,500–3,000 kg** (can vary based on length and type of rubber seal).

* **40-foot container:**

* Can hold **12-20 pallets** of PTFE Cladded Dam Rubber Seals.

* **Total weight**: \\~ **3,000–6,000 kg**, depending on the product\'s weight and length.

---

### **Labeling Information:**

Each bundle, crate, or box typically includes labels with the following information:

* **Product Name**: PTFE Cladded Dam Rubber Seal

* **Dimensions**: Length, width, and any relevant technical specifications (e.g., diameter of the coil).

* **Quantity**: Number of pieces or rolls per pallet, crate, or container.

* **Gross Weight**: Total weight of each bundle or crate.

* **Batch Number** or **Lot Number**: For traceability.

* **Manufacturer Details**: Name, address, and contact information of the manufacturer.

* **Country of Origin**: Relevant information for export purposes.

* **Handling Instructions**: Proper guidelines for handling, unloading, and storage to avoid damage to the seals.

* **Storage Conditions**: Recommended storage conditions to avoid direct sunlight, excessive moisture, or heat exposure.

---

### **Storage Recommendations:**

* **Temperature Control**: Store in a **cool, dry place** to prevent degradation of the rubber and PTFE.

* **Avoid Direct Sunlight**: Prolonged exposure to UV rays can damage the PTFE cladding and cause the rubber to deteriorate.

* **Flat Storage**: If stored in coils or rolls, ensure that they are placed on **flat surfaces** to prevent **uneven deformation** or damage.

* **Avoid Heavy Weight on Seals**: Do not stack heavy objects on the seals during storage to prevent compression or deformation.

---

### **Handling Recommendations:**

* **Use Forklifts** or **Pallet Jacks** to move pallets of PTFE Cladded Dam Rubber Seals, ensuring the product remains secure during transport.

* **Protect Edges**: Avoid dropping or impacting the rolled seals to prevent damage to the rubber and PTFE cladding.

* **Careful Uncoiling**: When removing the seals from their packaging, ensure they are **uncoiled slowly** and carefully to avoid **kinking** or **deformation**.

---

### **Shipping Considerations:**

* **Weatherproofing:** Ensure that the packaging is **adequate for moisture protection**, especially if transporting over long distances or through areas with **high humidity**.

* **Compliance with Export Regulations:** If shipping internationally, ensure the packaging complies with relevant **export regulations**, including **fumigation** or **ISPM-15** certification if necessary for wooden crates.

---

Would you like to know more about the **specific palletization** or **shipment preparation** for PTFE Cladded Dam Rubber Seals or any **custom packaging options** based on your needs?

---

### **Packaging Details: PTFE Cladded Dam Rubber Seal**

---

### **Product Overview:**

* **Product Name:** PTFE Cladded Dam Rubber Seal

* **Material:** A composite material made from **rubber** and a **PTFE (Polytetrafluoroethylene) cladding** for enhanced durability and resistance to water, chemicals, and extreme temperatures.

* **Applications:** Primarily used in **dam gates**, **sluices**, and **hydraulic structures** to provide a long-lasting seal for water and fluid control. PTFE offers excellent resistance to wear and corrosion.

* **Sizes and Configurations:** Available in various sizes, depending on the specific design requirements of the dam or water control structure. Common sizes include **lengths** ranging from **1 meter to 10 meters** and **widths** up to **200 mm** or more.

---

### **Packaging Configuration:**

#### **1. Coiling or Rolling:**

* **PTFE Cladded Dam Rubber Seals** are typically **rolled or coiled** into **circular or cylindrical shapes** to prevent damage and maintain their integrity during transportation.

* The seals may be wrapped in **protective film** or **plastic wrap** to keep them free from dirt and moisture.

* If the seals are particularly long (e.g., **10 meters** or more), they are **coiled tightly** and secured with **cable ties** or **plastic bands** to maintain their shape.

#### **2. Protective Wrapping:**

* **Plastic Shrink-Wrapping**: The entire rolled or coiled rubber seal is typically **shrink-wrapped** or covered with a layer of **protective plastic** to shield it from dirt, moisture, and UV exposure.

* **Foam or Rubber Inserts**: In some cases, protective foam or rubber inserts may be used around the **edges** or **ends** of the seal to protect the PTFE cladding from physical damage during handling or transportation.

* **Corner Protection**: If the seal\'s packaging includes a **box** or **crate**, **foam corner protectors** may be applied to minimize risk of sharp impacts.

#### **3. Bundling for Larger Orders:**

* For larger orders, multiple rolls or coils of PTFE Cladded Rubber Seals may be **bundled together** using **strapping** or **reinforced plastic ties**.

* Each bundle is then **shrink-wrapped** to secure the items and prevent them from shifting during shipment.

#### **4. Crating (for International Shipments):**

* For **international shipments** or when additional protection is required, the rolled or coiled rubber seals are placed into **wooden crates** or **strong cardboard boxes**.

* The crates or boxes are sealed to protect the product from external environmental factors such as **humidity** or **physical handling damage**.

* **Fumigation** may be applied to the crates to meet **international shipping standards** (e.g., ISPM-15) if required.

---

### **Container Loading (Approximate):**

* **20-foot container:**

* Typically holds around **6-10 pallets**, depending on the size of each rolled seal and the packaging method.

* **Total weight**: \\~ **1,500–3,000 kg** (can vary based on length and type of rubber seal).

* **40-foot container:**

* Can hold **12-20 pallets** of PTFE Cladded Dam Rubber Seals.

* **Total weight**: \\~ **3,000–6,000 kg**, depending on the product\'s weight and length.

---

### **Labeling Information:**

Each bundle, crate, or box typically includes labels with the following information:

* **Product Name**: PTFE Cladded Dam Rubber Seal

* **Dimensions**: Length, width, and any relevant technical specifications (e.g., diameter of the coil).

* **Quantity**: Number of pieces or rolls per pallet, crate, or container.

* **Gross Weight**: Total weight of each bundle or crate.

* **Batch Number** or **Lot Number**: For traceability.

* **Manufacturer Details**: Name, address, and contact information of the manufacturer.

* **Country of Origin**: Relevant information for export purposes.

* **Handling Instructions**: Proper guidelines for handling, unloading, and storage to avoid damage to the seals.

* **Storage Conditions**: Recommended storage conditions to avoid direct sunlight, excessive moisture, or heat exposure.

---

### **Storage Recommendations:**

* **Temperature Control**: Store in a **cool, dry place** to prevent degradation of the rubber and PTFE.

* **Avoid Direct Sunlight**: Prolonged exposure to UV rays can damage the PTFE cladding and cause the rubber to deteriorate.

* **Flat Storage**: If stored in coils or rolls, ensure that they are placed on **flat surfaces** to prevent **uneven deformation** or damage.

* **Avoid Heavy Weight on Seals**: Do not stack heavy objects on the seals during storage to prevent compression or deformation.

---

### **Handling Recommendations:**

* **Use Forklifts** or **Pallet Jacks** to move pallets of PTFE Cladded Dam Rubber Seals, ensuring the product remains secure during transport.

* **Protect Edges**: Avoid dropping or impacting the rolled seals to prevent damage to the rubber and PTFE cladding.

* **Careful Uncoiling**: When removing the seals from their packaging, ensure they are **uncoiled slowly** and carefully to avoid **kinking** or **deformation**.

---

### **Shipping Considerations:**

* **Weatherproofing:** Ensure that the packaging is **adequate for moisture protection**, especially if transporting over long distances or through areas with **high humidity**.

* **Compliance with Export Regulations:** If shipping internationally, ensure the packaging complies with relevant **export regulations**, including **fumigation** or **ISPM-15** certification if necessary for wooden crates.

---

Would you like to know more about the **specific palletization** or **shipment preparation** for PTFE Cladded Dam Rubber Seals or any **custom packaging options** based on your needs?

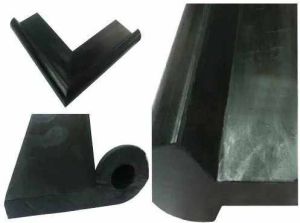

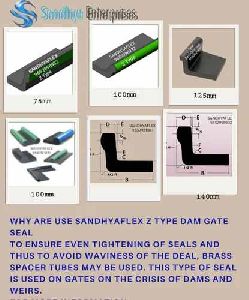

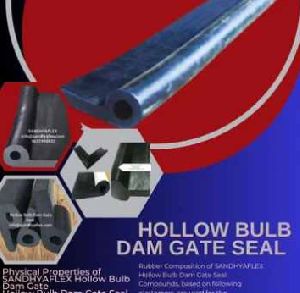

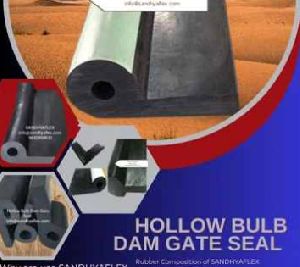

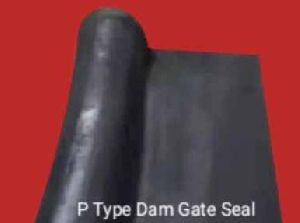

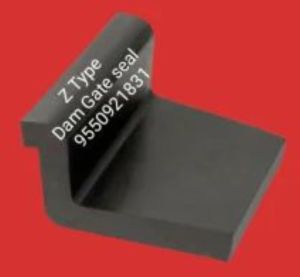

Dam gate seals are designed to either retain water, prevent water penetration, or limit contaminated run off in civil engineering a Dam Gate Seals Application: Quality of Rubber Concept dam gate seals are very well accepted by various Gate Designers, Fabricators as well as Contractors, and been installed by Government and Private agencies, In concrete dams, tunnels / spillways, head regulator of intake structure, by-pass channels and draft tube of power house, the flow of water is controlled with the help of hydraulic gates. To prevent flow of water past a closed gate, seals are provided either on the gate or on the metal frame in the gate slot,

- Here at The Rubber Company we manufacture a wide variety of rubber gate seals to suit any application and environment. We produce our gate and dam seals from high quality rubber compounds in order to preserve the service life of the seal. The entire gate seal range features a high tensile strength as standard. Our gate seals also feature excellent abrasion and tear resistant properties. These properties are crucial as it enables the seal to withstand frequent use, while also maintaining sealing properties, If required we can coat many of our rubber gate seals with a high quality PTFE coating. A key advantage of PTFE coating is that it significantly reduces surface friction without the need for lubricant. On average the coefficient of friction can be reduced by over 70%, regardless of the base rubber compound,

- Flat bottom seals on high head gates should project no more than the deflection required to seal e.g. 3-5mm. If required we can coat many of our rubber gate seals with a high quality PTFE coating.

Looking for "PTFE Cladded Dam Rubber Seal" ?

Meter