-

sandhyaprises@gmail.com -

View Mobile Number

| Business Type | Manufacturer, Exporter |

| Country of Origin | India |

| Certifications | ISO 9001:2008 |

| Weight | 100-300kg |

| Click to view more | |

Product Details

Type

Cement Feeding Pump

Application

Cement Feeding

Power

10-15kw,15-20kw,20-25kw

Condition

New

Color

Black

Product Code

Cement Feeding Rubber Hose

Port

Mumbai

Payment Terms

D/A

Delivery Time

5-7days

Packaging Details

SANDHYAFLEX Fly Ash Rubber Hose / Cement Feeding Rubber hose / Bulker Unloading Rubber Hose / / Bulker Air Rubber Hose

Working Pressure 10bar

S No Size Inches ID (mm) Weight of Rubber Hose perMtr Weight of Flange Rate/Mtr Fix Flange per side Swivel Flange per side SS Flange per side

1 3 76 4Kg 12kg 1200 900 1200 2700

2 4 102 5kg 14kg 1590 1100 1500 3300

3 5 127 7Kg 15 kg 2010 1200 1600 3600

4 6 152.4 9kg 19kg 2900 1425 1925 4300

SANDHYAFLEX Water Suction and Discharge Rubber Hose

Working Pressure 10bar

S No Size Inches ID (mm) Weight of Rubber Hose perMtr Weight of Flange Rate/Mtr Fix Flange per side Swivel Flange per side SS Flange per side

1 3 76 4Kg 12kg 960 900 1200 2700

2 4 102 5kg 14kg 1410 1100 1500 3300

3 5 127 7Kg 15 kg 1830 1200 1600 3600

4 6 152.4 9kg 19kg 2520 1425 1925 4300

5 8 200 12kg 37kg 3900 2800 3300 8400

8 10 250 17kg 41kg 5460 3800 4600 11500

9 12 300 21kg 45kg 7800 4750 5750 14500

10 14 350 11400 6500 7500 19500

11 16 400 14400 8000 9000 24000

SANDHYAFLEX Slurry Rubber hose /Mining Rubber Hose/Mud Rubber Hose/ Dewatering Rubber Hose

Working Pressure 10bar and 25Bar

S No Size Inches ID (mm) Weight of Rubber Hose perMtr Weight of Flange Rate/Mtr WP 10Bar Rate/Mtr WP 25 Bar Fix Flange per side Swivel Flange per side SS Flange per side

1 6 152.4 9kg 19kg 3450 4025 1425 1925 4300

2 8 203.2 12kg 37kg 5175 6325 2800 3300 8400

3 10 254 17kg 41kg 7475 9200 3800 4600 11500

s4 12 304.8 21kg 45kg 10925 13515 4750 5750 14500

Flange Dimension as per ASA 160# ANSI 16.5ASA 160# ANSI 16.5

Sr No Size OD of Flange in mm PCD mm Nos of Hose Holes Dia in mm

1 3” (75mm) 190.5 152.4 4 19

2 4” (100mm) 229 190.5 8 19

3 5” (125mm) 254 215.9 8 22.2

4 6’(150mm) 279.4 241.3 8 22.2

5 8” (200mm) 342.9 298.4 8 22.2

6 10” (250mm) 406.9 361.9 12 25.4

7 12” (300mm) 482.6 431.8 12 25.4

8 14” (350mm) 533.4 476.2 12 28.6

s9 16”(400mm) 596.9 539.7 16 28.6

10 18” (450mm) 635 577.8 16 31.7

11 20”(500mm) 698.5 635 20 31.7

12 24”(600mm) 812.8 749.3 20 34.9

Flange Dimension as per Table D

Sr No Size OD of Flange in mm PCD mm Nos of Hose Holes Dia in mm

1 3” (75mm) 184 146 4 16

2 4” (100mm) 216 178 8 16

3 5” (125mm) 254 210 8 16

4 6’(150mm) 279 235 8 19

Flange Dimension as per Table E

Sr No Size OD of Flange in mm PCD mm Nos of Hose Holes Dia in mm

1 3” (75mm) 184 146 4 16

2 4” (100mm) 216 178 8 16

3 5” (125mm) 254 210 8 16

4 6’(150mm) 279 235 8 19

Export Packing Date 01.01.2025

Dimension in CBM

Rubber Hose

Color Block

S No Size ID of

Rubber Hose Rubber Hose

Weight/mtrapprox Flange with Nipple Weight

01 Set Flange OD as per ASA 150# Length 6Mtr Width Flagge OD Height Flange OD CBM Weight/6mtr Hose in Kg

1 3” (75mm) 4kg 12 kg 190.5mm 6 0.191 0.191 0.219 36kg

2 4”(100mm) 5kg 13kg 229mm 6 0.229 0.229 0.315 43kg

3 5” (125mm) 7kg 14kg 254mm 6 0.254 0.254 0.387 56kg

4 6” (150mm) 9kg 19 kg 279.4mm 6 0.280 0.280 0.471 73kg

5 8”(200mm) 12kg 37kg 342.9 6 0.243 0.243 0.704 109kg

6 10” (250mm) 16kg 41 kg 406.9 6 0.407 0.407 0.994 137kg

7 12(300mm) 20Kg 45kg 482.6 6 0.483 0.483 1.400 165kg

8 14” ( 350mm) 6 0.534 0.534 1.709

9 16” (400mm) 6 0.597 0.597 2.1384

10 18” (450mm) 6 0.635 0.635 2.419

11 20” (500mm) 6 0.699 0.699 2.932

12 24”(600mm) 6 0.813 0.813 3.968

Working Pressure 10bar

S No Size Inches ID (mm) Weight of Rubber Hose perMtr Weight of Flange Rate/Mtr Fix Flange per side Swivel Flange per side SS Flange per side

1 3 76 4Kg 12kg 1200 900 1200 2700

2 4 102 5kg 14kg 1590 1100 1500 3300

3 5 127 7Kg 15 kg 2010 1200 1600 3600

4 6 152.4 9kg 19kg 2900 1425 1925 4300

SANDHYAFLEX Water Suction and Discharge Rubber Hose

Working Pressure 10bar

S No Size Inches ID (mm) Weight of Rubber Hose perMtr Weight of Flange Rate/Mtr Fix Flange per side Swivel Flange per side SS Flange per side

1 3 76 4Kg 12kg 960 900 1200 2700

2 4 102 5kg 14kg 1410 1100 1500 3300

3 5 127 7Kg 15 kg 1830 1200 1600 3600

4 6 152.4 9kg 19kg 2520 1425 1925 4300

5 8 200 12kg 37kg 3900 2800 3300 8400

8 10 250 17kg 41kg 5460 3800 4600 11500

9 12 300 21kg 45kg 7800 4750 5750 14500

10 14 350 11400 6500 7500 19500

11 16 400 14400 8000 9000 24000

SANDHYAFLEX Slurry Rubber hose /Mining Rubber Hose/Mud Rubber Hose/ Dewatering Rubber Hose

Working Pressure 10bar and 25Bar

S No Size Inches ID (mm) Weight of Rubber Hose perMtr Weight of Flange Rate/Mtr WP 10Bar Rate/Mtr WP 25 Bar Fix Flange per side Swivel Flange per side SS Flange per side

1 6 152.4 9kg 19kg 3450 4025 1425 1925 4300

2 8 203.2 12kg 37kg 5175 6325 2800 3300 8400

3 10 254 17kg 41kg 7475 9200 3800 4600 11500

s4 12 304.8 21kg 45kg 10925 13515 4750 5750 14500

Flange Dimension as per ASA 160# ANSI 16.5ASA 160# ANSI 16.5

Sr No Size OD of Flange in mm PCD mm Nos of Hose Holes Dia in mm

1 3” (75mm) 190.5 152.4 4 19

2 4” (100mm) 229 190.5 8 19

3 5” (125mm) 254 215.9 8 22.2

4 6’(150mm) 279.4 241.3 8 22.2

5 8” (200mm) 342.9 298.4 8 22.2

6 10” (250mm) 406.9 361.9 12 25.4

7 12” (300mm) 482.6 431.8 12 25.4

8 14” (350mm) 533.4 476.2 12 28.6

s9 16”(400mm) 596.9 539.7 16 28.6

10 18” (450mm) 635 577.8 16 31.7

11 20”(500mm) 698.5 635 20 31.7

12 24”(600mm) 812.8 749.3 20 34.9

Flange Dimension as per Table D

Sr No Size OD of Flange in mm PCD mm Nos of Hose Holes Dia in mm

1 3” (75mm) 184 146 4 16

2 4” (100mm) 216 178 8 16

3 5” (125mm) 254 210 8 16

4 6’(150mm) 279 235 8 19

Flange Dimension as per Table E

Sr No Size OD of Flange in mm PCD mm Nos of Hose Holes Dia in mm

1 3” (75mm) 184 146 4 16

2 4” (100mm) 216 178 8 16

3 5” (125mm) 254 210 8 16

4 6’(150mm) 279 235 8 19

Export Packing Date 01.01.2025

Dimension in CBM

Rubber Hose

Color Block

S No Size ID of

Rubber Hose Rubber Hose

Weight/mtrapprox Flange with Nipple Weight

01 Set Flange OD as per ASA 150# Length 6Mtr Width Flagge OD Height Flange OD CBM Weight/6mtr Hose in Kg

1 3” (75mm) 4kg 12 kg 190.5mm 6 0.191 0.191 0.219 36kg

2 4”(100mm) 5kg 13kg 229mm 6 0.229 0.229 0.315 43kg

3 5” (125mm) 7kg 14kg 254mm 6 0.254 0.254 0.387 56kg

4 6” (150mm) 9kg 19 kg 279.4mm 6 0.280 0.280 0.471 73kg

5 8”(200mm) 12kg 37kg 342.9 6 0.243 0.243 0.704 109kg

6 10” (250mm) 16kg 41 kg 406.9 6 0.407 0.407 0.994 137kg

7 12(300mm) 20Kg 45kg 482.6 6 0.483 0.483 1.400 165kg

8 14” ( 350mm) 6 0.534 0.534 1.709

9 16” (400mm) 6 0.597 0.597 2.1384

10 18” (450mm) 6 0.635 0.635 2.419

11 20” (500mm) 6 0.699 0.699 2.932

12 24”(600mm) 6 0.813 0.813 3.968

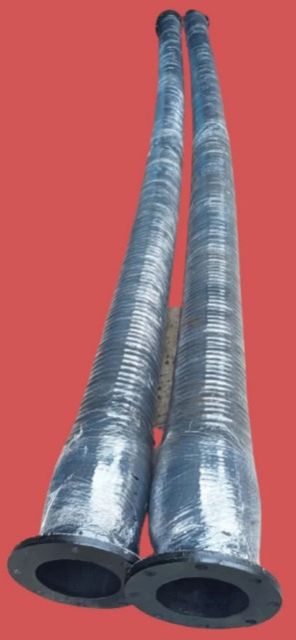

A Cement Feeding Rubber Hose is a specialized hose used in construction and industrial applications for the transportation of cement or other dry bulk materials. These hoses are typically designed to be durable, flexible, and resistant to wear and tear, making them suitable for heavy-duty tasks involving the transfer of abrasive substances like cement.

Key Features:- Material Composition: The hose is made from high-quality rubber, often reinforced with multiple layers of fabric or steel wire, ensuring both flexibility and strength.

- Abrasion Resistance: Cement is abrasive, and rubber hoses for this purpose are specially designed to resist damage caused by the roughness of the materials being pumped through them.

- Pressure Resistance: The hoses can withstand high pressures, as they are often used in applications where cement is pumped at high rates.

- Temperature Resistance: Some hoses are designed to endure the high temperatures associated with cement and concrete.

- Flexibility: The rubber construction ensures the hose can bend and move easily, making it suitable for various construction environments.

- Durability: Cement feeding rubber hoses are designed for heavy-duty use and can handle long-term use in tough environments.

- Concrete Pumping: Used to transport cement and concrete mixtures from a mixing site to construction areas.

- Cement Plants: For feeding raw cement materials or additives in production processes.

- Mining: Transporting cement or slurry for filling, binding, or other related activities.

These hoses are crucial for ensuring efficient and safe handling of cement in construction projects,

Looking for "Cement Feeding Pump" ?

Piece