-

sandhyaprises@gmail.com -

View Mobile Number

Other Products

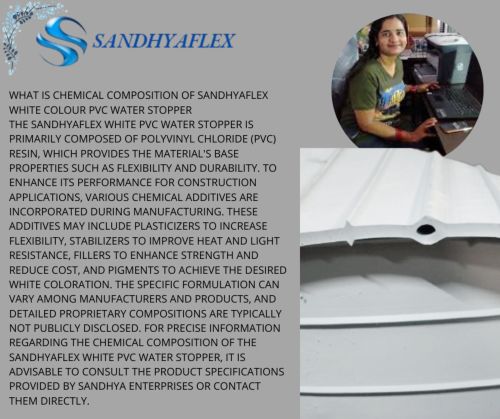

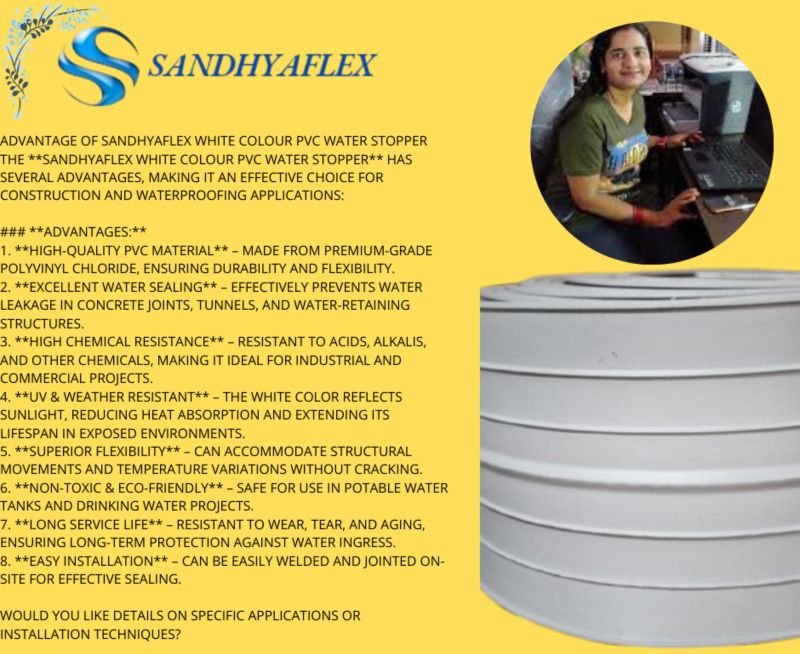

Leading Manufacturers, Exporters, Wholesaler, Retailer of 250x8mm PVC Water Stopper, Bridge Center Bulb PVC Water Stopper, Cylendrica Rubber Fender, Electrical Insulating Mat, Fire and Fighting Canvas Hose, Insulatin Rubber Mat, Mud Rubber Sucition Hose, PVC Color Braided Pipe, PVC Membrane Foil, Scaffolding Anchor Nut, Scaffolding Tie Rod, Waterproof Membranes, White Transparent Silicon Rubber Sheet and Wing Nuts from Hyderabad.

| Business Type | Manufacturer, Exporter |

| Length | 25-30mtr |

| Size | 230x8mm |

| Application | Construction |

| Surface Treatment | Water Proofing |

| Condition | New |

| Material | Pvc |

| Brand Name | SNDHYAFLEX |

| Product Code | 230PVCWS |

| Port | mumbai |

| Payment Terms | D/P, Other |

| Delivery Time | 2 to 7 days |

| Packaging Details | packing in 25Mtr/Roll |

A **250mm x 8mm PVC Water Stopper** refers to a specific size of water stopper used for preventing water seepage through joints in concrete structures. Here\\\'s a breakdown of its details:

\\n\\n

### Specifications:

\\n- **Width**: 250 mm (25 cm), indicating the horizontal width of the water stopper.

\\n- **Thickness**: 8 mm, which refers to the overall thickness of the PVC material.

\\n\\n

### Characteristics:

\\n- **Material**: Made of flexible PVC (Polyvinyl Chloride), providing durability, flexibility, and resistance to chemicals and weather conditions.

\\n- **Center Bulb or Flat Profile**: Depending on the design, it could either have a center bulb (for expansion joints) or be flat (for construction or contraction joints).

\\n\\n

### Applications:

\\n- **Water Retaining Structures**: Commonly used in water tanks, reservoirs, dams, and swimming pools.

\\n- **Underground Structures**: Basements, tunnels, and retaining walls to stop water seepage through construction joints.

\\n- **Concrete Expansion Joints**: In bridges, culverts, and other large concrete structures where water penetration is a concern.

\\n\\n

### Advantages:

\\n- **Waterproofing**: Effectively seals joints to prevent water leakage.

\\n- **Flexibility**: Accommodates movement in the structure while maintaining a waterproof seal.

\\n- **Durability**: High resistance to weathering, chemicals, and environmental stress.

\\n\\n

The **250mm x 8mm PVC Water Stopper** is used in medium- to large-scale concrete structures, providing a robust and durable solution for waterproofing joints.

| Business Type | Exporter |

| Length | 25-30mtr |

| Size | 150mm Width |

| Application | Construction |

| Condition | New |

| Color | Black |

| Material | Pvc |

| Brand Name | SNDHYAFLEX |

| Product Code | 150mmPVCWS |

| Port | mumbai |

| Delivery Time | 2 to 7 days |

| Packaging Details | 25mtr/Roll |

The Sandhyaflex 300mm Width PVC Water Stopper is a type of water-resistant sealing product commonly used in construction and civil engineering projects. This particular water stopper is made of PVC (Polyvinyl Chloride), which is known for its durability, flexibility, and resistance to water and chemicals. With a width of 300mm, it is designed to be used in joints and cracks in concrete structures, such as in:

-

Foundations: To prevent water leakage in basements, underground structures, or water containment areas.

-

Dams and reservoirs: To prevent seepage through expansion joints in water-retaining structures.

-

Tunnels: For waterproofing between tunnel sections.

-

Swimming pools: For preventing water leakage between pool walls and floors.

-

Water treatment plants: To seal joints in structures exposed to water pressure.

PVC water stoppers are generally used in areas where there is a significant risk of water leakage, and they help in preventing water from seeping through joints between concrete sections. The flexibility of PVC allows it to accommodate slight movements in the structure while maintaining a tight seal.

Would you like more information on how this product works, or on how to install it in construction projects?

| Eccentrically Rubber Fender | 12000 to 20000/Mtr |

| Product Code | CRF |

| Port | kakinada |

| Payment Terms | T/T |

| Delivery Time | 15 to 30days |

| Packaging Details | Packing with HDPE Cover |

Sandhya enterprises manufacturer and supplier of cylindrical rubber fender as per customer requirement. D type and cylendrical rubber fender. Sandhya enterprises run by mithilesh chaudhary having 20 years experience in various company. Elastomeric bridge bearing pad, strip seal expansion join, rubber d fender, rubber sheet, hyraulic rubber hose and industrial rubber suction hose.

| Thickness | 2.0mm to 3.5mm |

| Max Withstanding Temperature | 200Deg C |

We are a quality-driven firm and make sure that our offerings are properly kept and processed. For this, we have installed all the in-house storage facility that helps us in meeting bulk and urgent requirements of the clients. We have successfully emerged as a distinguished supplier of Electrical Insulating Mat that is highly demanded amidst the customers.

Features :

- Excellent insulation

- High quality

- Perfect finish

size:25mm ID to 250mm ID

Length:30Mtr

Sandhya Enterprises run by Mithilesh Chaudhary having 20 years experience in Rubber and PVC Products.

| Type | Electrical Rubber Mats |

| Material | Synthetic Rubber |

| Thickness | 2.0mm,2.5mm and 3.0mm |

| Application | Electrical Mats |

| Color | Black |

| Hardness | Soft |

| Power Source | 3.3,11.0 and 33.0kv |

| Warranty | 6month date of Dispatch |

| Certificate | ISO 9001 2015 |

| Electrical Insulating Rubber Mat | 600 to 900/Mtr |

| Product Code | EIRM |

| Port | kakinada |

| Payment Terms | T/T |

| Delivery Time | 7 to 15days |

| Packaging Details | Packing with HDPE Cover |

Sandhya Enterprises Manufacturer and Supplier of Insulating Rubber Mat as per IS:15652:2006 Specification: Thickness:2.0mm, 2.5mm,3.0mm and 3.5mm Width:1 Mtr and 1.2Mtr Length:2Mtr to 10Mtr Color: Black, Red, Blue, Orange.

| Type | Suction Type |

| Material | Syntetic Rubber |

| Shape | Spiral/Corrugated Tope |

| Thickness | 8mm to 25mm |

| Length | 15 Mtr |

| Technics | 10 to 25kg W.P. |

| Standard | MEETS IS : 5137 W.P. 10kgf/cm2 MIN. B.P. 40 kgf/cm2 50 |

| Black ,Green and Blue | 25000 |

| Product Code | Mud and Slurry Rubber Suction Hose |

Sand and Grovel Hose

MEETS IS : 5137

W.P. 10kgf/cm2

MIN. B.P. 40 kgf/cm2

50.0

63.0

75.0

100.0

150.0

200.0

Tube : Highly abrasion resistant soft natural rubber

compound.

Reinforcement : Woven/Braided or spirally wound

textile of high strength synthetic fibres.

Electrical bonding : low resistant electrical

bonding wire in-corporated between the

reinforcement plies to pro vide electrical continuity along

the whole length of the hose.

Cover : Cloth marked finish cover, resistant to weather

and abrasion.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Brand Name | SNDHYAFLEX |

| Material | Pvc |

| Color | Multicolor |

| Feature | Soft |

| Type | Pvc Braided Hose Pipe |

| Diameter | 12mm |

| Product Code | PVCBP |

| Port | mumbai |

| Delivery Time | 7 to 15 days |

| Packaging Details | packing in Coil |

PVC color braided pipes are flexible hoses made of polyvinyl chloride (PVC) material with reinforcement in the form of braided fibers. These pipes are commonly used for various applications due to their flexibility, durability, and resistance to chemicals. The braided reinforcement provides added strength, making the pipes suitable for both low and high-pressure applications. Here are some key features and uses of PVC color braided pipes:

1. **Material:** PVC color braided pipes are typically made from PVC resin, which is a versatile and widely used thermoplastic material. The braided reinforcement is often made of polyester or nylon.

2. **Color Options:** These pipes come in various colors, and the color is often incorporated into the outer layer of the PVC material. The color can serve practical purposes, such as color-coding for specific applications or aesthetics.

3. **Braided Reinforcement:** The braided layer enhances the strength of the PVC pipe, making it resistant to kinking, crushing, and deformation. The braiding also provides stability under pressure, making these pipes suitable for both suction and delivery applications.

4. **Flexibility:** PVC color braided pipes are known for their flexibility, allowing for easy handling and installation. This flexibility is particularly beneficial in applications where the pipes need to navigate around obstacles or tight spaces.

5. **Chemical Resistance:** PVC is generally resistant to a wide range of chemicals, making these pipes suitable for conveying various liquids. However, the specific chemical resistance may vary depending on the formulation of the PVC material.

6. **Temperature Resistance:** PVC color braided pipes are suitable for a range of temperatures, but it's essential to check the manufacturer's specifications to ensure they meet the requirements of your specific application.

7. **Applications:** Common applications for PVC color braided pipes include water supply, irrigation, gardening, air and gas supply, industrial fluid transfer, and various other uses where a flexible and durable hose is required.

8. **Sizes and Specifications:** PVC color braided pipes come in various sizes and specifications to meet different flow and pressure requirements. It's crucial to select the appropriate size and type based on the intended application.

9. **Installation:** These pipes are relatively easy to install, and they can be connected using fittings compatible with PVC material. Proper installation ensures optimal performance and longevity.

When using PVC color braided pipes, it's important to follow the manufacturer's guidelines, including recommended temperature and pressure ratings. Regular inspection and maintenance can help ensure the pipes remain in good condition and perform effectively over time.

| Business Type | Exporter, Supplier |

| Shape | Square |

| Color | Black |

| Application | Floor |

| Style | Anitque |

| Feature | Easy To Fit |

| Pattern | Plain |

| Type | Pvc Membrane Foil |

| Product Code | PVCWPM |

| Port | mumbai |

| Delivery Time | 7 to 15 days |

| Packaging Details | packing in coil |

PVC waterproofing membranes are flexible, durable, and widely used for waterproofing various structures. Here are the primary uses and applications:

### 1. **Roof Waterproofing**

- **Flat Roofs**: PVC membranes are ideal for flat or low-slope roofs in commercial, industrial, and residential buildings.

- **Green Roofs**: They are often used in green or vegetative roofs due to their waterproofing efficiency and root resistance.

- **Decks and Terraces**: They provide a durable surface for these exposed areas.

### 2. **Underground Structures**

- **Foundations and Basements**: PVC membranes are applied on the outer side of foundation walls to prevent water ingress from soil.

- **Tunnels**: PVC membranes are used in tunnel construction to prevent water penetration in underground transit systems or drainage tunnels.

### 3. **Water Containment Structures**

- **Ponds and Reservoirs**: PVC membranes are used to waterproof ponds, water reservoirs, and irrigation canals to prevent water leakage.

- **Waterproofing Swimming Pools**: They are applied beneath pool tiles or directly as a pool liner for waterproofing.

### 4. **Bridges and Civil Engineering Projects**

- **Bridge Decks**: Waterproofing bridge decks using PVC membranes protects the structure from water damage, salt, and other corrosive agents.

- **Parking Garages**: PVC membranes are used to waterproof parking structures, especially the underground sections.

### 5. **Bathroom and Wet Areas**

- **Bathrooms and Wet Rooms**: PVC membranes are used for interior waterproofing in wet areas such as bathrooms, showers, and kitchens.

### Key Benefits of PVC Waterproofing Membranes:

- **Flexibility**: Adapts well to movement or thermal expansion.

- **Durability**: PVC membranes resist UV radiation, weathering, and chemical exposure.

- **Ease of Installation**: They can be easily welded, providing seamless waterproof protection.

- **Resistance**: Excellent resistance to moisture, root penetration, punctures, and environmental wear.

PVC membranes are ideal for environments exposed to water and harsh weather conditions, offering long-lasting protection for various structures.

| Business Type | Manufacturer, Exporter, Supplier |

| Size | 0-15mm, Cool — So You're Working With **brand,Color,Size** Data. This Is Super Common For Anything From Fashion To Electronics To Packaging. Here's How It Typically Looks,Depending On Your Use Case. ### |

| Usage | Automobile Fittings |

| Color | Shiny Golden,Cool — So You're Working With **brand, Color, Size** Data. This Is Super Common For Anything From Fashion To Electronics To Packaging. Here's How It Typically Looks, Depending On Your Use Case. ### |

| Surface Finishing | Power Coated |

| Material | Copper |

| Brand Name | Canco |

| Head Shape | Round Head |

| Product Code | C1019663125-16 |

| Port | mumbai |

| Payment Terms | D/A |

| Delivery Time | 7to 15days |

| Packaging Details | Could you clarify what you mean by "packaging details"? Are you referring to: - Product packaging (e.g., dimensions, materials, labeling)? - Packaging design? - Shipping and logistics packaging? - Regulatory or compliance info? - Something specific (like for a product or industry)? Let me know a bit more so I can help you better! |

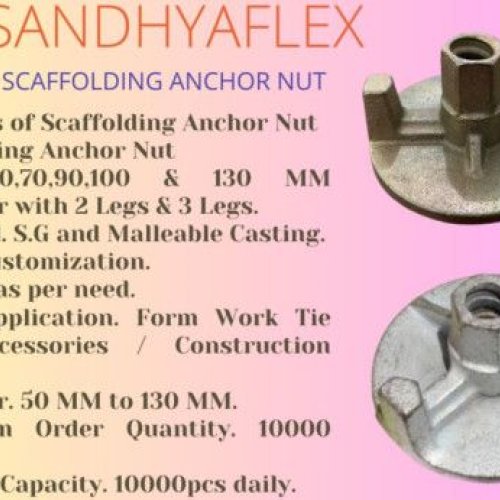

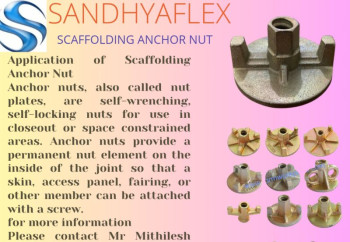

Scaffolding anchor nuts are critical components used in construction scaffolding systems. These nuts serve several important functions in ensuring the stability, safety, and flexibility of scaffolding structures. Here are some common uses and applications of scaffolding anchor nuts:

1. **Securing Scaffolding Frames**: Anchor nuts are used to secure scaffolding frames to the ground or to other structural components. They provide a stable anchor point for the scaffolding structure, preventing it from shifting or collapsing.

2. **Adjusting Scaffolding Heights**: Scaffolding anchor nuts are often used in conjunction with adjustable base plates or screw jacks. By turning the nut, workers can easily adjust the height of the scaffolding to suit the requirements of the construction project.

3. **Connecting Scaffold Tubes**: Anchor nuts are used to connect scaffold tubes or pipes together, forming the vertical and horizontal members of the scaffolding structure. These nuts provide a secure connection point that can withstand the weight of workers and construction materials.

4. **Supporting Scaffold Boards**: Scaffold boards or planks are laid across horizontal scaffold tubes to create a working platform for construction workers. Anchor nuts are used to secure these boards in place, ensuring they remain stable and level during use.

5. **Providing Stability**: Scaffolding anchor nuts play a crucial role in providing stability to the entire scaffolding structure. By anchoring the scaffolding to the ground or to adjacent structures, anchor nuts help prevent swaying or tipping, especially in windy conditions or on uneven terrain.

6. **Facilitating Easy Assembly and Disassembly**: Anchor nuts are designed for easy installation and removal, allowing for quick assembly and disassembly of scaffolding structures. This is particularly important in construction projects where time is of the essence.

7. **Compatibility with Various Scaffolding Systems**: Anchor nuts are versatile components that can be used with various types of scaffolding systems, including tube and clamp scaffolding, ring lock scaffolding, and cup lock scaffolding. This makes them a popular choice among construction professionals.

Overall, scaffolding anchor nuts are essential components that contribute to the safety, stability, and functionality of scaffolding structures in construction projects. Their versatility and ease of use make them indispensable tools for construction workers and scaffolding contractors.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Mild Steel |

| Country of Origin | India |

| Number Of Flower | Scaffolding Tie Rod |

| Application | Industrial |

| Finishing | Polished |

| Brand Name | SNDHYAFLEX |

| Condition | New |

| Shape | Rectangular |

| Product Code | C1019663125-16 |

| Port | mumbai |

| Payment Terms | D/P |

| Delivery Time | 2 to 7 days |

| Packaging Details | packaging as per dimension |

Scaffolding tie rods are critical components used in construction scaffolding systems for various applications. Here are some of their main uses and applications:

1. **Structural Stability**: Scaffolding tie rods are primarily used to provide structural stability to scaffolding structures. They help distribute loads evenly across the scaffolding system, minimizing the risk of collapse or failure, especially in tall or complex scaffolds.

2. **Tying Scaffolding Frames Together**: Tie rods are used to connect and tie scaffolding frames together horizontally and vertically. This connection reinforces the entire scaffold structure, ensuring it remains stable and secure during construction activities.

3. **Bracing and Diagonal Support**: Tie rods are often utilized as diagonal bracing elements within the scaffolding system. They help distribute lateral loads, such as wind forces or uneven weight distribution, and prevent the scaffold from swaying or tipping over.

4. **Supporting Platforms and Decks**: Tie rods are used to support scaffold platforms or decks, providing additional stability and load-bearing capacity. They help distribute the weight of workers, equipment, and construction materials evenly across the scaffold, reducing the risk of platform failure.

5. **Adjusting Scaffold Heights**: In some scaffolding systems, tie rods can be used to adjust the height of scaffold platforms or decks. By adjusting the length of the tie rods, workers can raise or lower the scaffold to the desired height, accommodating changes in elevation or terrain.

6. **Anchoring to Structures**: Tie rods are often used to anchor scaffolding to existing structures, such as buildings or walls. This anchoring helps secure the scaffold in place, preventing movement or displacement during construction activities.

7. **Temporary Support during Construction**: In addition to their use in scaffolding, tie rods can also be employed as temporary supports during various construction tasks. They can provide additional reinforcement to formwork, temporary bracing, or other temporary structures on the construction site.

8. **Compatibility with Various Scaffolding Systems**: Tie rods are compatible with different types of scaffolding systems, including tube and clamp scaffolding, ring lock scaffolding, cup lock scaffolding, and others. This versatility allows for their widespread use in various construction projects.

Overall, scaffolding tie rods play a crucial role in ensuring the stability, safety, and functionality of scaffolding structures in construction projects. Their versatility, load-bearing capacity, and ability to provide structural reinforcement make them essential components for construction workers and scaffolding contractors alike.

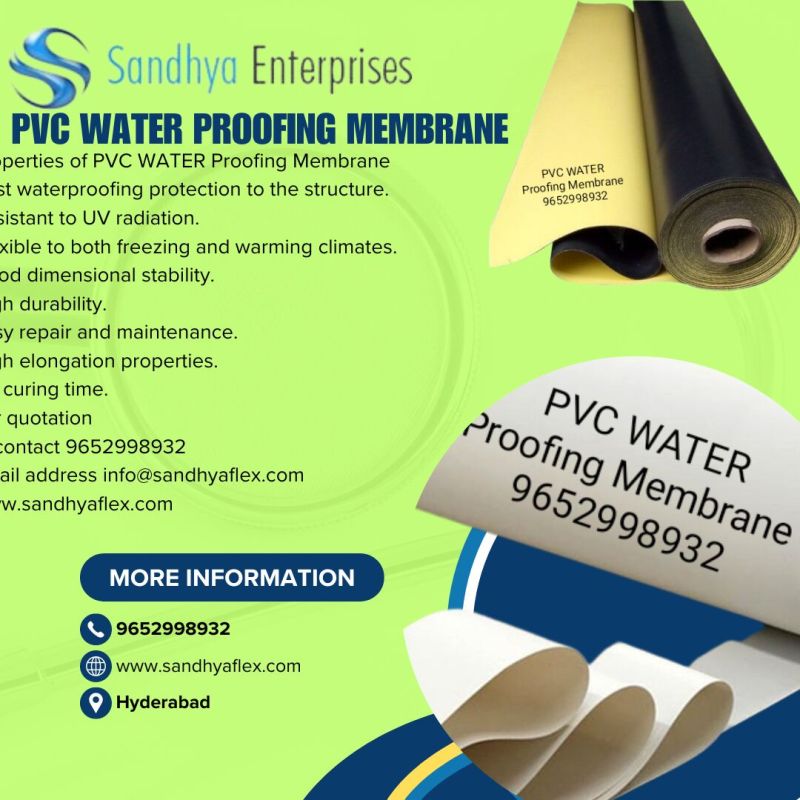

| Business Type | Exporter, Supplier |

| Brand Name | SNDHYAFLEX |

| Color | Black and Yellow |

| Certificate | ISO;9001 2015 |

| Type | Sheet |

| Country of Origin | India |

| Item | PVC Waterproof membrane |

| Port | mumbai |

| Delivery Time | 7 to 15 days |

| Packaging Details | packing in coil |

PVC waterproofing membranes are flexible, durable, and widely used for waterproofing various structures. Here are the primary uses and applications:

### 1. **Roof Waterproofing**

- **Flat Roofs**: PVC membranes are ideal for flat or low-slope roofs in commercial, industrial, and residential buildings.

- **Green Roofs**: They are often used in green or vegetative roofs due to their waterproofing efficiency and root resistance.

- **Decks and Terraces**: They provide a durable surface for these exposed areas.

### 2. **Underground Structures**

- **Foundations and Basements**: PVC membranes are applied on the outer side of foundation walls to prevent water ingress from soil.

- **Tunnels**: PVC membranes are used in tunnel construction to prevent water penetration in underground transit systems or drainage tunnels.

### 3. **Water Containment Structures**

- **Ponds and Reservoirs**: PVC membranes are used to waterproof ponds, water reservoirs, and irrigation canals to prevent water leakage.

- **Waterproofing Swimming Pools**: They are applied beneath pool tiles or directly as a pool liner for waterproofing.

### 4. **Bridges and Civil Engineering Projects**

- **Bridge Decks**: Waterproofing bridge decks using PVC membranes protects the structure from water damage, salt, and other corrosive agents.

- **Parking Garages**: PVC membranes are used to waterproof parking structures, especially the underground sections.

### 5. **Bathroom and Wet Areas**

- **Bathrooms and Wet Rooms**: PVC membranes are used for interior waterproofing in wet areas such as bathrooms, showers, and kitchens.

### Key Benefits of PVC Waterproofing Membranes:

- **Flexibility**: Adapts well to movement or thermal expansion.

- **Durability**: PVC membranes resist UV radiation, weathering, and chemical exposure.

- **Ease of Installation**: They can be easily welded, providing seamless waterproof protection.

- **Resistance**: Excellent resistance to moisture, root penetration, punctures, and environmental wear.

PVC membranes are ideal for environments exposed to water and harsh weather conditions, offering long-lasting protection for various structures.

Color: White Transparent.

thickness:1mm to 50mm

Width:1Mtr to 1.2Mtr.

Length::2Mtr to 15 Mtr

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Size | Ah,Got It! When You See **"brand,Color,Size"** Listed Together Like That,It's Usually In The Context Of **product Listings,Inventory,Order Forms,Or Packing Lists**—especially In Retail,Fashion,Nice! When You See **"material,Color,Size"**,It’s,Cou |

| Head Shape | Round Head |

| Surface Finishing | Power Coated |

| Material | Copper,Nice! When You See **"material, Color, Size"**, It’s Usually In The Context Of Product Descriptions, Manufacturing Specs, Or Order Forms—especially For Clothing, Furniture, Packaging, Or Construction |

| Brand Name | Kundan,Could You Clarify What You're Asking For With "brand Color Size"? Are You Looking For: - Brand Guidelines For Color And Sizing? - A Specific Brand’s Color Codes And Logo Sizes? - Help Choosing A Bran,Could you clarify what you're asking about |

| Color | Golden,Could You Clarify What You're Asking For With "brand Color Size"? Are You Looking For: - Brand Guidelines For Color And Sizing? - A Specific Brand’s Color Codes And Logo Sizes? - Help Choosing A Bran,Could you clarify what you're asking about |

| Country of Origin | India |

| Corrosion Resistance | Yes |

| Port | mumbai |

| Payment Terms | D/P |

| Delivery Time | 7to 15days |

| Packaging Details | Could you clarify what you mean by “packaging details”? Are you referring to: - Packaging details for a product (e.g., dimensions, materials, labeling)? - How to write packaging details for a shipment or inventory? - Design elements for a product's packaging? - Something else? Let me know what you're working on, and I’ll tailor the info accordingly! |

Scaffolding wing nuts are essential components used in construction scaffolding systems, offering several important functions and applications:

1. **Securing Scaffold Joints**: Wing nuts are primarily used to secure scaffold joints by attaching them to scaffold bolts or threaded rods. The wings on the nut allow for easy hand tightening, eliminating the need for additional tools during assembly or disassembly.

2. **Adjusting Scaffold Heights**: Wing nuts are often employed in conjunction with adjustable base plates or screw jacks to adjust the height of scaffolding structures. By turning the wing nut, workers can easily raise or lower the scaffold to the desired height, ensuring proper alignment and stability.

3. **Connecting Scaffold Tubes**: Wing nuts are used to connect scaffold tubes or pipes together, forming the vertical and horizontal members of the scaffolding structure. These nuts provide a secure connection point that can withstand the weight of workers and construction materials.

4. **Supporting Scaffold Boards**: Scaffold boards or planks are laid across horizontal scaffold tubes to create a working platform for construction workers. Wing nuts are used to secure these boards in place, ensuring they remain stable and level during use.

5. **Providing Stability**: Scaffolding wing nuts play a crucial role in providing stability to the entire scaffolding structure. By securing joints and connections, wing nuts help prevent swaying or tipping, especially in windy conditions or on uneven terrain.

6. **Facilitating Easy Assembly and Disassembly**: Wing nuts are designed for easy installation and removal, allowing for quick assembly and disassembly of scaffolding structures. This is particularly important in construction projects where time is of the essence.

7. **Compatibility with Various Scaffolding Systems**: Scaffolding wing nuts are versatile components that can be used with various types of scaffolding systems, including tube and clamp scaffolding, ring lock scaffolding, cup lock scaffolding, and others. This makes them a popular choice among construction professionals.

Overall, scaffolding wing nuts are indispensable components that contribute to the safety, stability, and functionality of scaffolding structures in construction projects. Their versatility, ease of use, and ability to provide secure connections make them essential tools for construction workers and scaffolding contractors alike.