-

sandhyaprises@gmail.com -

View Mobile Number

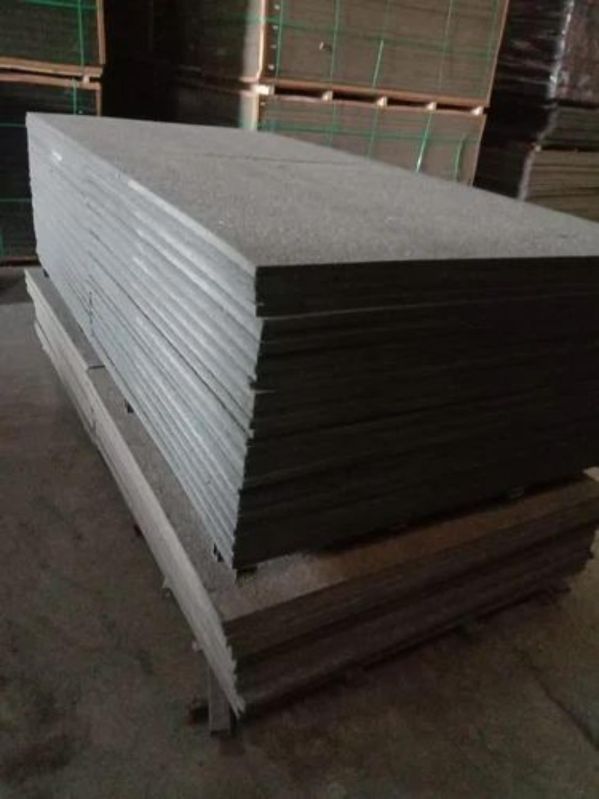

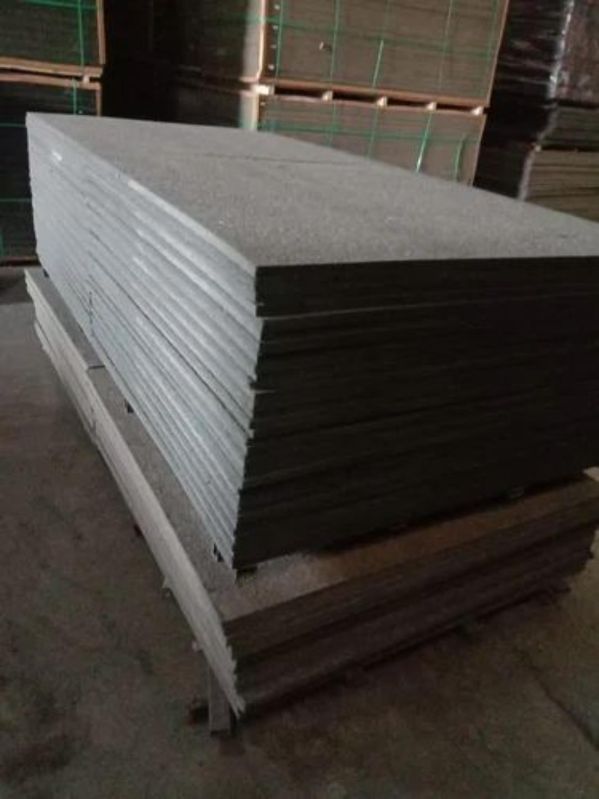

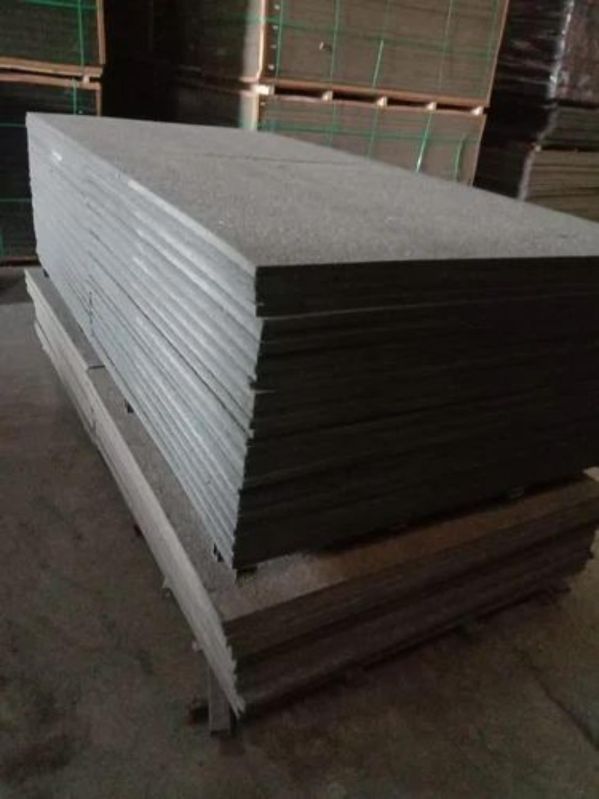

Expansion joint Filler Board

Leading Manufacturers, Exporters, Wholesaler, Retailer of Bitumen Expansion Joint Filler Board, Bitumen Mastic Pad, Bitumen Shalitex Board, Black Expansion Joint Filler Board, Expansion Joint Bitumen Mastic Pad, Expansion Joint Mastic Pad, Shalitex Joint Filler Board and Supreme Shalitex Board from Hyderabad.

| Business Type | Manufacturer, Exporter, Supplier |

| Condition | New |

| Driven Type | Battery |

| Brand Name | Sandhyaflex |

| Country of Origin | India |

| Application | Roads And National High Ways, Bridges |

| Feature | Bitumen Expansion Joint Fillers Are Designed To Provide Specific Features And Properties To |

| Hardness | The hardness of bitumen expansion joint filler boards can vary depending on the specific ma |

| Temperature | The temperature of the bitumen expansion joint filler board in a construction applicatio |

| Port | The **Port of Dispatch** for **Polyvinyl Chloride (PVC) Resin** depends on the manufacturing locatio |

| Payment Terms | L/C |

| Delivery Time | 7 to 15 days |

The Sandhyaflex Bitumen Mastic Pad is a high-performance, durable pad used in construction and infrastructure projects for vibration damping, load distribution, and providing a protective cushion between structural components. It\\\'s commonly used in bridge bearings, building foundations, and industrial applications.

\\n✅ Features:

\\n- \\n

- \\n

Material Composition:

\\n- \\n

- Made from a combination of bitumen and mineral fillers, offering excellent load-bearing and cushioning properties. \\n

- Reinforced with fabric or fibers for added strength and longevity. \\n

\\n - \\n

Design:

\\n- \\n

- Available in various thicknesses and sizes to suit different applications. \\n

- Offers uniform load distribution to prevent structural damage. \\n

\\n - \\n

Weather and Chemical Resistance:

\\n- \\n

- Resistant to water, chemicals, and environmental elements, ensuring long-term performance. \\n

- Maintains structural integrity even under extreme temperatures. \\n

\\n

🛠 Applications:

\\n- \\n

- Bridge Bearings: Used as a cushioning layer to absorb vibrations and distribute loads in bridges. \\n

- Building Foundations: Provides vibration damping and load management between structural components. \\n

- Industrial Equipment: Installed under heavy machinery to minimize vibration and noise. \\n

- Rail Tracks and Pipelines: Acts as a shock-absorbing material in rail systems and pipelines. \\n

📏 Specifications (May Vary Based on Model)

\\n- \\n

- Thickness: Typically available from 10 mm to 50 mm or customized based on application. \\n

- Size: Can be provided in standard or customized dimensions. \\n

- Load Capacity: Designed to handle high loads, ranging from 10 tons to 100 tons. \\n

- Temperature Range: Operates effectively between -20°C to +80°C. \\n

🔎 Advantages:

\\n- \\n

- Excellent vibration absorption and noise reduction. \\n

- Prevents structural wear and tear by evenly distributing loads. \\n

- Resistant to aging, weathering, and environmental damage. \\n

- Easy to install and maintain. \\n

- Provides long-term performance with minimal maintenance. \\n

\\n

If you\\\'d like further information on specific sizes, technical data sheets, or pricing, feel free to ask!

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Jolly Board |

| Country of Origin | India |

| Thickness | 12,20 And 25mm |

| Shape | Square |

| Size | 2' x 4' |

| Usage/ Application | Expansion Joint Filling Expansion joint filler boards play a crucial role in vario |

| Density | The density of expansion joint filler boards can vary depending on the type of material used |

| Application Industry | Construction |

| Compression Set | 20.00% |

| Packaging Type | Packing 10 to 15Nos/PKD with Polythine Cover Export Packing Dimension in CBM Expansio |

| Water Absorption | The water absorption of expansion joint filler boards depends on the type of materi |

The Sandhyaflex Bitumen Mastic Pad is a high-performance, durable pad used in construction and infrastructure projects for vibration damping, load distribution, and providing a protective cushion between structural components. It's commonly used in bridge bearings, building foundations, and industrial applications.

✅ Features:-

Material Composition:

- Made from a combination of bitumen and mineral fillers, offering excellent load-bearing and cushioning properties.

- Reinforced with fabric or fibers for added strength and longevity.

-

Design:

- Available in various thicknesses and sizes to suit different applications.

- Offers uniform load distribution to prevent structural damage.

-

Weather and Chemical Resistance:

- Resistant to water, chemicals, and environmental elements, ensuring long-term performance.

- Maintains structural integrity even under extreme temperatures.

- Bridge Bearings: Used as a cushioning layer to absorb vibrations and distribute loads in bridges.

- Building Foundations: Provides vibration damping and load management between structural components.

- Industrial Equipment: Installed under heavy machinery to minimize vibration and noise.

- Rail Tracks and Pipelines: Acts as a shock-absorbing material in rail systems and pipelines.

- Thickness: Typically available from 10 mm to 50 mm or customized based on application.

- Size: Can be provided in standard or customized dimensions.

- Load Capacity: Designed to handle high loads, ranging from 10 tons to 100 tons.

- Temperature Range: Operates effectively between -20°C to +80°C.

- Excellent vibration absorption and noise reduction.

- Prevents structural wear and tear by evenly distributing loads.

- Resistant to aging, weathering, and environmental damage.

- Easy to install and maintain.

- Provides long-term performance with minimal maintenance.

If you'd like further information on specific sizes, technical data sheets, or pricing, feel free to ask!

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Thickness | 25 Mm |

| Material | Bitumen Pad |

| Brand Name | sandhyaflex |

| Driven Type | rubber |

| Condition | New |

| Power Type | AC |

| Shape | Rectangular, Square |

| Packaging Type | HDPE Bag |

| Size | Hey! Could you clarify what you mean by "size"? Are you asking about file size, clothing size, image dimensions, or something else entirely? |

| Product Code | sandhyaflex |

| Port | Got it! It sounds like you're referring to **"Port of Dispatch."** In logistics and shipp |

| Payment Terms | D/A |

| Delivery Time | depends |

| Packaging Details | Could you please clarify what you mean by **"packaging details"**? Are you referring to: - Packaging details for a specific **product**? - Packaging **design** and **materials**? - Legal/compliance **labeling requirements**? - A format or template for writing packaging details (like for an online store or product spec sheet)? - Something else? Let me know a bit more so I can give you exactly what you need! |

Bitumen Shalitex board is a specialized type of construction material primarily used as a formwork system for casting concrete structures. Here\\\'s an overview of its features and applications:

1. **Material Composition**: Bitumen Shalitex boards are typically constructed using high-density polyethylene (HDPE) or polypropylene (PP) plastic infused or coated with bitumen. This combination provides the board with durability, flexibility, and resistance to moisture, chemicals, and weathering.

2. **Bitumen Coating**: The bitumen coating on the Shalitex board\\\'s surface serves several purposes. It enhances the board\\\'s waterproofing capabilities, ensuring that the concrete does not adhere to the board during casting. Additionally, it creates a smooth surface finish on the concrete, minimizing surface defects and enhancing the overall appearance of the structure.

3. **Reusable**: Bitumen Shalitex boards are designed to be reusable, allowing them to be used multiple times for different casting projects. After the concrete has cured, the boards can be easily cleaned and prepared for the next casting application, reducing waste and overall project costs.

4. **Ease of Installation**: Bitumen Shalitex boards are lightweight and easy to handle, making them quick and convenient to install on construction sites. They can be easily cut to size using standard cutting tools, allowing for customizations to fit specific project requirements.

5. **Versatility**: Bitumen Shalitex boards are suitable for a wide range of concrete casting applications, including walls, columns, beams, slabs, and other structural elements. They can be used in both horizontal and vertical casting scenarios, providing versatility for various construction projects.

6. **Applications**: Bitumen Shalitex boards are commonly used in residential, commercial, and industrial construction projects for both interior and exterior concrete casting applications. They are particularly well-suited for projects where high-quality concrete finishes are desired.

7. **Benefits**: The use of Bitumen Shalitex boards offers several benefits, including improved construction efficiency, reduced labor costs, enhanced concrete finish quality, and minimized surface defects such as honeycombing and air bubbles.

Overall, Bitumen Shalitex boards are reliable and cost-effective solutions for achieving superior concrete finishes in construction projects. Their durability, ease of use, and versatility make them a preferred choice for contractors and builders seeking efficient and high-quality concrete casting solutions.

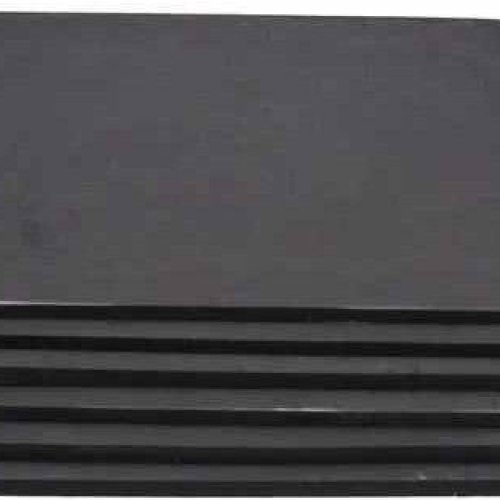

| Business Type | Manufacturer, Exporter, Supplier |

| Color | Black |

| Country of Origin | India |

| Application | Jointing For RCC And Concrete Construction Expansion Joint Filler Boards Play A Cr |

| Size | As Per Customer Requirement Export Packing Dimension In CBM Expansion Joint Filler Board Size 2 |

| Material | Bitumen Pad |

| Density | The Density Of Expansion Joint Filler Boards Can Vary Depending On The Type Of Material Used |

| Feature | Features : - Closed Cell Hence Negligible Water / Water Vapour Absorption - Resilient - Rec |

| Board Size | 4' x 2' |

| Shape | Expansion joint filler boards typically come in the form of rectangular or square-shaped strip |

| Packaging Type | Smooth Export Packing Dimension in CBM Expansion Joint Filler Board Size 2 Feet and 4 |

| Water Absorption | The water absorption of expansion joint filler boards depends on the type of materi |

| Hardness | The hardness of expansion joint filler boards can vary based on the type of material used a |

| Temperature | Features : - Closed cell hence negligible water / water vapour absorption - Resilient - |

Application

· Filling structural expansion and structural separation joints in block and in situ concrete construction including screed floors, motorways, roads, runways, pedestrian areas, bridges, curbs, basements, retaining walls, vertical structures, subways and other structures.

· Filling all types of expansion joints in piers and lateral supports like abutments

· Roads, Airport Runways, Taxi tracks and various other joints of concrete floors

Advantages

· Closed cell structure resulting negligible water/moisture absorption

· Excellent recovery after compression

· High resistance to chemical like most acids, alkalies oil and hydrocarbon

· Bitumen free hence non staining and free from bleeding

· Easy to cut, hand and install

· Rot proof hence does not age and disintegrate over prolonged use

· Use of ShaliBar/Backer rod is optional

Application Methodology

· Remove dust, flakes or foreign particles by jet of dry air to clean the surface.

· Cut ShaliTex Expansion Joint Filler Board of appropriate width from the desired sizes and place the same in the groove in a way to flush with the external surface except for space required for ShaliBar and sealants

· In case of a new casting ShaliTex Expansion Joint Filler Board of appropriate width is fixed with copper screws before pouring concrete. The width is designed to flush with the external surface except for space required for ShaliBar and Sealants

· In highway construction, ShaliTex Expansion Joint Filler Board is plac

Low moisture absorption due to bitumen impregnation. Standard Bitumen content 10-20-35%. Other possibilities upon request

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Ruber |

| Shape | Square, Rectangular |

| Country of Origin | India |

| Brand Name | sandhyaflex |

| Color | black |

| Finishing | Polished |

| Size | Export Packing Dimension in CBM Expansion Joint Filler Board Size 2 Feet and 4Feet Color Block S No |

| Product Code | sandhyaflex |

| Port | The **port of dispatch** for rubber cords depends on the **manufacturer's location** and the **buyer |

| Payment Terms | D/A, D/P |

| Delivery Time | depends |

| Packaging Details | packaging as per dimension |

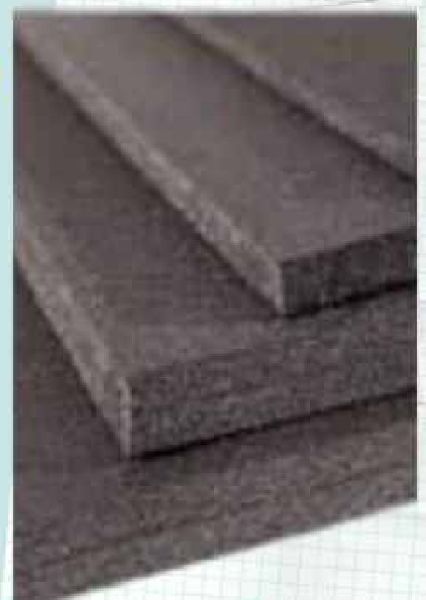

- It is a cross-linked, pre-moulded, high performance joint filler board. It is readily compressible and ensures low load transfer. Applications: Structural expansion joint in concrete brick and block work Isolation to infill panels Bridge decks, abutments, pier hinge joint etc. As a backup support for sealant.

- The purpose of the expansion of expansion joint is to protect the structure from damage due to temperature changes, whereas the purpose of expansion joint filler board is to fill the gap created by expansion joint or isolation joints to avoid any foreign materials get into the gap.

-

- Impregnated with Bitumen in various percentages, it is a perfect base material for expansion joint fillers. The board’s compression and recovery characteristics confirm to the U.K., U.S.A. and Indian Standards much above the required averages.

-

- It is available in a wide range of sizes, both as boards & strips in thicknesses of 10 MM, 12 MM, 18 MM, 19 MM, 25 MM. Jolly Expansion Joint Filler displays excellent resistance to compression, with outstanding recovery characteristics.

-

- Joint fillers are relatively a compressed material so that it does not fail as the concrete grows around it and shrinks due to temperature change or movement. The joint fillers prevents untimely failure of the concrete structure. Following are the various types of joint filler materials as follows:Expansion joint bitumen mastic pads are commonly used in construction—especially in roads, bridges, and concrete structures—to accommodate thermal expansion and contraction. These pads offer several benefits. Here are the key advantages:

1. Flexibility and Movement Accommodation

-

Bitumen mastic pads can absorb expansion and contraction movements in structures caused by temperature changes, shrinkage, or vibration.

-

Prevents cracking and structural damage by allowing movement at the joints.

-

Bitumen is naturally waterproof, and the mastic form ensures a tight seal that prevents water ingress.

-

Protects the joint and surrounding structure from moisture, which is critical for longevity—especially in bridges and pavements.

-

High resistance to weathering, UV radiation, and aging.

-

Maintains elasticity and performance over time even under harsh environmental conditions.

-

Mastic pads can bear moderate loads, making them suitable for areas subjected to traffic or structural pressure.

-

Provides cushioning and load transfer across jointed sections.

-

Can be preformed or poured in place.

-

No complex equipment needed; installation is relatively straightforward, which reduces labor costs.

-

Once installed, they typically require little to no maintenance over their lifespan.

-

Resistant to erosion and chemical attack from road salts and oils.

-

Compared to other expansion joint systems (like mechanical ones), bitumen mastic pads are more affordable.

-

Cost savings on both material and labor.

If you’re looking at a specific use case (like bridges, pavements, or buildings), I can tailor the pros to that context. Want to dive deeper?

-

- Joint fillers are relatively a compressed material so that it does not fail as the concrete grows around it and shrinks due to temperature change or movement. The joint fillers prevents untimely failure of the concrete structure. Following are the various types of joint filler materials as follows:Expansion joint bitumen mastic pads are commonly used in construction—especially in roads, bridges, and concrete structures—to accommodate thermal expansion and contraction. These pads offer several benefits. Here are the key advantages:

1. Flexibility and Movement Accommodation

| Business Type | Manufacturer, Exporter, Supplier |

| Feature | Fine Finishing, Light Weigth |

| Country of Origin | India |

| Brand Name | sandhyaflex |

| Material | rubber |

| Shape | Square |

| Design Printing | Hey! Could you tell me a bit more about what you mean by "design printing"? Are you looking for: - |

| Application | Got it! Are you thinking about: - **Designing a printing-related application** (like a web app for |

| Type | Expansion Joints |

| Size | Export Packing Dimension in CBM Expansion Joint Filler Board Size 2 Feet and 4Feet Color Block S No |

| Product Code | sandhyaflex |

| Port | A **port of dispatch** refers to the location (typically a seaport or airport) from which goods are |

| Payment Terms | D/A, D/P |

| Delivery Time | 7to 15days |

| Packaging Details | packaging as per dimension |

- \\n

- It is a cross-linked, pre-moulded, high performance joint filler board. It is readily compressible and ensures low load transfer. Applications: Structural expansion joint in concrete brick and block work Isolation to infill panels Bridge decks, abutments, pier hinge joint etc. As a backup support for sealant. \\n

- The purpose of the expansion of expansion joint is to protect the structure from damage due to temperature changes, whereas the purpose of expansion joint filler board is to fill the gap created by expansion joint or isolation joints to avoid any foreign materials get into the gap. \\n

- \\n

- \\n

- Impregnated with Bitumen in various percentages, it is a perfect base material for expansion joint fillers. The board’s compression and recovery characteristics confirm to the U.K., U.S.A. and Indian Standards much above the required averages. \\n

- \\n

- \\n

- It is available in a wide range of sizes, both as boards & strips in thicknesses of 10 MM, 12 MM, 18 MM, 19 MM, 25 MM. Jolly Expansion Joint Filler displays excellent resistance to compression, with outstanding recovery characteristics. \\n

- \\n

- \\n

- Joint fillers are relatively a compressed material so that it does not fail as the concrete grows around it and shrinks due to temperature change or movement. The joint fillers prevents untimely failure of the concrete structure. Following are the various types of joint filler materials as follows: \\n

\\n

\\n

\\n

| Business Type | Manufacturer, Exporter, Supplier |

| Thicknesses | 50 Mm |

| Type | Joint Filler Board |

| Country of Origin | India |

| Packaging Type | Bundle, HDPE Bag |

| Material | Polyethylene, Bitumen Pad |

| Color | Black, Natural |

| Shape | Square |

| Form | Board |

| Payment Terms | L/C |

| Delivery Time | depends |

| Packaging Details | Here are the complete **Packaging Details** for your **Sandhyaflex BackPVC Waterstopper**: --- ### **Packaging Details: Sandhyaflex BackPVC Waterstopper** * **Brand**: Sandhyaflex * **Product Type**: BackPVC Waterstopper * **Standard Roll Length**: 25 meters per roll * **Roll Widths Available**: 150mm, 230mm, 305mm (custom sizes available) * **Roll Thickness**: 6mm to 10mm (based on specification) --- #### **Packaging Specifications:** | Item | Description | | ------------------------------------ | ------------------------------------------------------------------------------------------ | | **Packaging Type** | Heavy-Duty HDPE Wrapping or Shrink-Wrapped Rolls | | **Protection** | Moisture-proof and dust-resistant packaging | | **Handling** | Rolls are strapped with plastic/nylon bands for lifting | | **Labeling** | Each roll carries branded labeling with size, batch no., production date, and company logo | | **Storage Instructions** | Store in a cool, dry place, away from direct sunlight and sharp objects | | **Shipping Units** | Rolls are palletized or bundled depending on order volume | | **Export Packaging (if applicable)** | Wooden crate/pallet with fumigation certificate (on request) | --- Would you like me to format this into a professional **catalog sheet or brochure section** with your company branding and logo? |

Shalitex expansion joint filler boards are specialized construction materials used to fill and seal expansion joints in concrete structures. Here's an overview of their features and applications:

1. **Material Composition**: Shalitex expansion joint filler boards are typically made from high-density polyethylene (HDPE), polypropylene (PP), or similar plastic materials. These materials offer durability, flexibility, and resistance to moisture, chemicals, and weathering, making them suitable for construction applications.

2. **Design**: The filler boards are designed with a compressible and resilient structure that allows them to accommodate movement in concrete structures. They are available in various sizes, thicknesses, and shapes to fit different joint dimensions and configurations.

3. **Waterproofing**: Shalitex expansion joint filler boards help to prevent water infiltration through expansion joints, protecting the underlying concrete structure from moisture damage, corrosion, and deterioration. Some filler boards may have additional waterproofing features or coatings for enhanced protection.

4. **Flexibility**: The compressible nature of Shalitex expansion joint filler boards allows them to adapt to the movement of concrete structures caused by factors such as temperature changes, settling, or seismic activity. This flexibility ensures that the joint remains sealed and intact over time.

5. **Ease of Installation**: Shalitex expansion joint filler boards are lightweight and easy to handle, making them quick and convenient to install on construction sites. They can be easily cut to size using standard cutting tools, allowing for customizations to fit specific project requirements.

6. **Applications**: Shalitex expansion joint filler boards are commonly used in various construction projects, including highways, bridges, parking structures, sidewalks, and industrial floors. They are suitable for filling expansion joints in concrete slabs, walls, or other structural elements, providing a flexible and durable seal.

| Business Type | Manufacturer, Exporter, Supplier |

| Application | Furniture |

| Color | Brown |

| Thickness | 1/8 Inch |

| Country of Origin | India |

| Size (sq ft) | 8x4 |

| Wood Type | Hardwood |

| Core Material | Poplar |

The Sandhyaflex Bitumen Mastic Pad is a high-performance, durable pad used in construction and infrastructure projects for vibration damping, load distribution, and providing a protective cushion between structural components. It's commonly used in bridge bearings, building foundations, and industrial applications.

✅ Features:-

Material Composition:

- Made from a combination of bitumen and mineral fillers, offering excellent load-bearing and cushioning properties.

- Reinforced with fabric or fibers for added strength and longevity.

-

Design:

- Available in various thicknesses and sizes to suit different applications.

- Offers uniform load distribution to prevent structural damage.

-

Weather and Chemical Resistance:

- Resistant to water, chemicals, and environmental elements, ensuring long-term performance.

- Maintains structural integrity even under extreme temperatures.

- Bridge Bearings: Used as a cushioning layer to absorb vibrations and distribute loads in bridges.

- Building Foundations: Provides vibration damping and load management between structural components.

- Industrial Equipment: Installed under heavy machinery to minimize vibration and noise.

- Rail Tracks and Pipelines: Acts as a shock-absorbing material in rail systems and pipelines.

- Thickness: Typically available from 10 mm to 50 mm or customized based on application.

- Size: Can be provided in standard or customized dimensions.

- Load Capacity: Designed to handle high loads, ranging from 10 tons to 100 tons.

- Temperature Range: Operates effectively between -20°C to +80°C.

- Excellent vibration absorption and noise reduction.

- Prevents structural wear and tear by evenly distributing loads.

- Resistant to aging, weathering, and environmental damage.

- Easy to install and maintain.

- Provides long-term performance with minimal maintenance.

If you'd like further information on specific sizes, technical data sheets, or pricing, feel free to ask!