-

sandhyaprises@gmail.com -

View Mobile Number

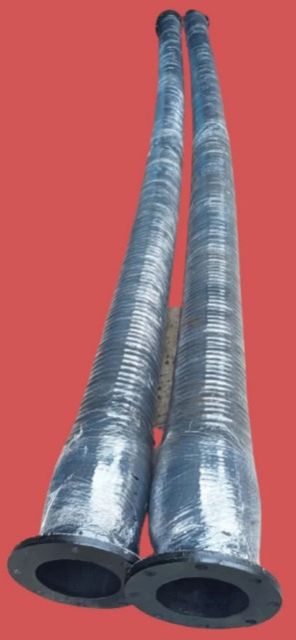

Cement Feeding Rubber Hose

Leading Manufacturers, Exporters, Wholesaler, Retailer of 100mm Cementing Rubber Hose, 125mm Cementing Rubber Hose, 5Mtr Cement Feeding Rubber Hose with Swival Flange, Cement Feeding Pump, Cement Grouting Rubber Hose, Rubber Cement Feeding Hose and Sanhdyaflex Cement Feeding Rubber Hose from Hyderabad.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Rubber,Rubber |

| Working Pressure | 10 Bar |

| Number Of Flower | Vacuum Hose Pipe |

| Layers | 8 Layers |

| Packaging Type | Open |

| Length | 6 Mtr max |

| Temperature | 1 to 100 Deg C Max |

| Thickness | As per customers requirement |

The Sandhyaflex Cement Feeding Rubber Hose is a specialized industrial hose designed for transferring cement and other abrasive materials in construction and industrial applications. Here\\\'s a detailed overview of its features and uses:

\\n✅ Features:\\n- \\n

- Material: Made from a high-quality, abrasion-resistant rubber lining to withstand the rough nature of cement and other bulk materials. \\n

- Reinforcement: Typically reinforced with multiple layers of synthetic fabric or steel wire to ensure durability and high-pressure resistance. \\n

- Outer Cover: Weather and wear-resistant outer layer to endure harsh working environments. \\n

- Flexibility: Designed for flexibility, making it easy to handle and install in complex systems. \\n

- \\n

- Used in cement plants for transferring dry cement. \\n

- Suitable for bulk cement tankers for loading and unloading cement. \\n

- Ideal for pneumatic conveying systems in construction sites. \\n

- Can be used in cement silos and concrete batching plants. \\n

- \\n

- Size: Typically available in sizes from 2 inches to 6 inches in diameter. \\n

- Length: Can be customized as per requirements. \\n

- Working Pressure: Usually ranges from 5 to 10 bar. \\n

- Temperature Range: Suitable for temperatures ranging from -20°C to +80°C. \\n

- Abrasion Resistance: High resistance to wear, ensuring a longer service life. \\n

- \\n

- Long-lasting performance in tough conditions. \\n

- Easy to install and maintain. \\n

- Excellent resistance to abrasion and weather. \\n

- Available in different sizes and specifications for various industrial needs. \\n

\\n

If you need further details on pricing, availability, or technical data, feel free to ask!

| Business Type | Manufacturer, Exporter, Supplier |

| Color | Black |

| Finishing | Coated |

| Material | Rubber |

| Shape | Round |

| Country of Origin | India |

| Type | Vacuum Hose Pipe |

| Brand Name | sandhyaflex |

| Pressure | 10-15kga |

| Product Code | Cement Feeding Rubber Hose |

| Port | Mumbai |

| Payment Terms | D/A |

| Delivery Time | 5-7days |

| Packaging Details | SANDHYAFLEX Fly Ash Rubber Hose / Cement Feeding Rubber hose / Bulker Unloading Rubber Hose / / Bulker Air Rubber Hose Working Pressure 10bar S No Size Inches ID (mm) Weight of Rubber Hose perMtr Weight of Flange Rate/Mtr Fix Flange per side Swivel Flange per side SS Flange per side 1 3 76 4Kg 12kg 1200 900 1200 2700 2 4 102 5kg 14kg 1590 1100 1500 3300 3 5 127 7Kg 15 kg 2010 1200 1600 3600 4 6 152.4 9kg 19kg 2900 1425 1925 4300 SANDHYAFLEX Water Suction and Discharge Rubber Hose Working Pressure 10bar S No Size Inches ID (mm) Weight of Rubber Hose perMtr Weight of Flange Rate/Mtr Fix Flange per side Swivel Flange per side SS Flange per side 1 3 76 4Kg 12kg 960 900 1200 2700 2 4 102 5kg 14kg 1410 1100 1500 3300 3 5 127 7Kg 15 kg 1830 1200 1600 3600 4 6 152.4 9kg 19kg 2520 1425 1925 4300 5 8 200 12kg 37kg 3900 2800 3300 8400 8 10 250 17kg 41kg 5460 3800 4600 11500 9 12 300 21kg 45kg 7800 4750 5750 14500 10 14 350 11400 6500 7500 19500 11 16 400 14400 8000 9000 24000 SANDHYAFLEX Slurry Rubber hose /Mining Rubber Hose/Mud Rubber Hose/ Dewatering Rubber Hose Working Pressure 10bar and 25Bar S No Size Inches ID (mm) Weight of Rubber Hose perMtr Weight of Flange Rate/Mtr WP 10Bar Rate/Mtr WP 25 Bar Fix Flange per side Swivel Flange per side SS Flange per side 1 6 152.4 9kg 19kg 3450 4025 1425 1925 4300 2 8 203.2 12kg 37kg 5175 6325 2800 3300 8400 3 10 254 17kg 41kg 7475 9200 3800 4600 11500 s4 12 304.8 21kg 45kg 10925 13515 4750 5750 14500 Flange Dimension as per ASA 160# ANSI 16.5ASA 160# ANSI 16.5 Sr No Size OD of Flange in mm PCD mm Nos of Hose Holes Dia in mm 1 3” (75mm) 190.5 152.4 4 19 2 4” (100mm) 229 190.5 8 19 3 5” (125mm) 254 215.9 8 22.2 4 6’(150mm) 279.4 241.3 8 22.2 5 8” (200mm) 342.9 298.4 8 22.2 6 10” (250mm) 406.9 361.9 12 25.4 7 12” (300mm) 482.6 431.8 12 25.4 8 14” (350mm) 533.4 476.2 12 28.6 s9 16”(400mm) 596.9 539.7 16 28.6 10 18” (450mm) 635 577.8 16 31.7 11 20”(500mm) 698.5 635 20 31.7 12 24”(600mm) 812.8 749.3 20 34.9 Flange Dimension as per Table D Sr No Size OD of Flange in mm PCD mm Nos of Hose Holes Dia in mm 1 3” (75mm) 184 146 4 16 2 4” (100mm) 216 178 8 16 3 5” (125mm) 254 210 8 16 4 6’(150mm) 279 235 8 19 Flange Dimension as per Table E Sr No Size OD of Flange in mm PCD mm Nos of Hose Holes Dia in mm 1 3” (75mm) 184 146 4 16 2 4” (100mm) 216 178 8 16 3 5” (125mm) 254 210 8 16 4 6’(150mm) 279 235 8 19 Export Packing Date 01.01.2025 Dimension in CBM Rubber Hose Color Block S No Size ID of Rubber Hose Rubber Hose Weight/mtrapprox Flange with Nipple Weight 01 Set Flange OD as per ASA 150# Length 6Mtr Width Flagge OD Height Flange OD CBM Weight/6mtr Hose in Kg 1 3” (75mm) 4kg 12 kg 190.5mm 6 0.191 0.191 0.219 36kg 2 4”(100mm) 5kg 13kg 229mm 6 0.229 0.229 0.315 43kg 3 5” (125mm) 7kg 14kg 254mm 6 0.254 0.254 0.387 56kg 4 6” (150mm) 9kg 19 kg 279.4mm 6 0.280 0.280 0.471 73kg 5 8”(200mm) 12kg 37kg 342.9 6 0.243 0.243 0.704 109kg 6 10” (250mm) 16kg 41 kg 406.9 6 0.407 0.407 0.994 137kg 7 12(300mm) 20Kg 45kg 482.6 6 0.483 0.483 1.400 165kg 8 14” ( 350mm) 6 0.534 0.534 1.709 9 16” (400mm) 6 0.597 0.597 2.1384 10 18” (450mm) 6 0.635 0.635 2.419 11 20” (500mm) 6 0.699 0.699 2.932 12 24”(600mm) 6 0.813 0.813 3.968 |

A slurry rubber hose is a type of hose specifically designed to transport abrasive and thick fluids, known as slurries, in industries like mining, construction, or wastewater treatment. Slurries typically consist of a mixture of water and solid particles, such as sand, gravel, or other sediments.

Features of Slurry Rubber Hoses:-

Durability: These hoses are made from high-quality rubber compounds that provide excellent resistance to abrasion, wear, and impact. This makes them ideal for moving slurries, which can be harsh and abrasive.

-

Flexibility: Slurry rubber hoses maintain flexibility even under harsh working conditions, allowing for easy installation and movement in tight spaces.

-

High Pressure Resistance: Slurry hoses are designed to withstand high-pressure environments, which is crucial in many slurry transfer applications.

-

Reinforced Construction: They often have multiple layers of reinforcement, such as fabric or steel wire, to enhance strength and prevent collapse under pressure.

-

Chemical Resistance: Depending on the materials used in the hose, slurry rubber hoses can be resistant to a wide range of chemicals that may be present in the slurry mix.

- Mining and Mineral Processing: Transporting minerals, ores, and other solids suspended in water.

- Construction: Pumping concrete or other thick mixtures.

- Wastewater Treatment: Moving slurry-like waste materials in various stages of treatment.

- Agriculture: Transporting slurry materials like manure or liquid fertilizers.

Would you like more specific information on a certain type or manufacturer of slurry rubber hoses?

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Rubber |

| Shape | Round |

| Color | Black |

| Packaging Type | Packing With HDPE Cover |

| Type | Vacuum Hose Pipe |

| Length | 6m |

| Nominal Size | 100mm,125mm |

| Layers | Depend of Dimension |

The Sandhyaflex Cement Feeding Rubber Hose with Swivel Flange is a specialized hose used primarily in construction and industrial applications for the transport of cement, dry bulk materials, and similar substances. This hose is designed to provide efficient and durable performance while feeding cement into mixers, silos, or other systems.

Key features of the Sandhyaflex Cement Feeding Rubber Hose with Swivel Flange include:

-

Swivel Flange: The swivel flange design allows for flexibility and movement of the hose without putting undue stress on the connections. It makes the hose easier to handle, and the swivel feature ensures that the hose does not twist or kink during use.

-

Rubber Construction: The hose is made from high-quality rubber, which gives it excellent durability and resistance to wear, abrasion, and weathering. It is designed to handle harsh conditions, making it ideal for cement and bulk material feeding.

-

Pressure Resistance: It is built to withstand high pressure during cement feeding operations, ensuring that the hose remains intact and performs well under load.

-

Abrasion Resistance: The rubber material is resistant to the abrasiveness of cement, minimizing wear and extending the lifespan of the hose.

-

Flexibility: The hose is designed to be highly flexible, making it easier to maneuver and position, especially in confined spaces or when connecting to various machinery.

-

High-Temperature Resistance: Some versions of this hose can handle elevated temperatures, which is important in industrial settings where heat may be a concern.

-

Easy Installation and Maintenance: The swivel flange makes installation and maintenance simpler, as it minimizes the need for complex connections and ensures a secure and leak-free setup.

This hose is typically used in construction sites for feeding cement into mixing trucks, silos, or other equipment, ensuring a smooth and efficient material flow. Its durability and ease of use make it an essential tool for the construction and cement industries.

| Business Type | Manufacturer, Exporter |

| Country of Origin | India |

| Certifications | ISO 9001:2008 |

| Weight | 100-300kg |

| Type | Cement Feeding Pump |

| Application | Cement Feeding |

| Power | 10-15kw,15-20kw,20-25kw |

| Condition | New |

| Color | Black |

| Product Code | Cement Feeding Rubber Hose |

| Port | Mumbai |

| Payment Terms | D/A |

| Delivery Time | 5-7days |

| Packaging Details | SANDHYAFLEX Fly Ash Rubber Hose / Cement Feeding Rubber hose / Bulker Unloading Rubber Hose / / Bulker Air Rubber Hose Working Pressure 10bar S No Size Inches ID (mm) Weight of Rubber Hose perMtr Weight of Flange Rate/Mtr Fix Flange per side Swivel Flange per side SS Flange per side 1 3 76 4Kg 12kg 1200 900 1200 2700 2 4 102 5kg 14kg 1590 1100 1500 3300 3 5 127 7Kg 15 kg 2010 1200 1600 3600 4 6 152.4 9kg 19kg 2900 1425 1925 4300 SANDHYAFLEX Water Suction and Discharge Rubber Hose Working Pressure 10bar S No Size Inches ID (mm) Weight of Rubber Hose perMtr Weight of Flange Rate/Mtr Fix Flange per side Swivel Flange per side SS Flange per side 1 3 76 4Kg 12kg 960 900 1200 2700 2 4 102 5kg 14kg 1410 1100 1500 3300 3 5 127 7Kg 15 kg 1830 1200 1600 3600 4 6 152.4 9kg 19kg 2520 1425 1925 4300 5 8 200 12kg 37kg 3900 2800 3300 8400 8 10 250 17kg 41kg 5460 3800 4600 11500 9 12 300 21kg 45kg 7800 4750 5750 14500 10 14 350 11400 6500 7500 19500 11 16 400 14400 8000 9000 24000 SANDHYAFLEX Slurry Rubber hose /Mining Rubber Hose/Mud Rubber Hose/ Dewatering Rubber Hose Working Pressure 10bar and 25Bar S No Size Inches ID (mm) Weight of Rubber Hose perMtr Weight of Flange Rate/Mtr WP 10Bar Rate/Mtr WP 25 Bar Fix Flange per side Swivel Flange per side SS Flange per side 1 6 152.4 9kg 19kg 3450 4025 1425 1925 4300 2 8 203.2 12kg 37kg 5175 6325 2800 3300 8400 3 10 254 17kg 41kg 7475 9200 3800 4600 11500 s4 12 304.8 21kg 45kg 10925 13515 4750 5750 14500 Flange Dimension as per ASA 160# ANSI 16.5ASA 160# ANSI 16.5 Sr No Size OD of Flange in mm PCD mm Nos of Hose Holes Dia in mm 1 3” (75mm) 190.5 152.4 4 19 2 4” (100mm) 229 190.5 8 19 3 5” (125mm) 254 215.9 8 22.2 4 6’(150mm) 279.4 241.3 8 22.2 5 8” (200mm) 342.9 298.4 8 22.2 6 10” (250mm) 406.9 361.9 12 25.4 7 12” (300mm) 482.6 431.8 12 25.4 8 14” (350mm) 533.4 476.2 12 28.6 s9 16”(400mm) 596.9 539.7 16 28.6 10 18” (450mm) 635 577.8 16 31.7 11 20”(500mm) 698.5 635 20 31.7 12 24”(600mm) 812.8 749.3 20 34.9 Flange Dimension as per Table D Sr No Size OD of Flange in mm PCD mm Nos of Hose Holes Dia in mm 1 3” (75mm) 184 146 4 16 2 4” (100mm) 216 178 8 16 3 5” (125mm) 254 210 8 16 4 6’(150mm) 279 235 8 19 Flange Dimension as per Table E Sr No Size OD of Flange in mm PCD mm Nos of Hose Holes Dia in mm 1 3” (75mm) 184 146 4 16 2 4” (100mm) 216 178 8 16 3 5” (125mm) 254 210 8 16 4 6’(150mm) 279 235 8 19 Export Packing Date 01.01.2025 Dimension in CBM Rubber Hose Color Block S No Size ID of Rubber Hose Rubber Hose Weight/mtrapprox Flange with Nipple Weight 01 Set Flange OD as per ASA 150# Length 6Mtr Width Flagge OD Height Flange OD CBM Weight/6mtr Hose in Kg 1 3” (75mm) 4kg 12 kg 190.5mm 6 0.191 0.191 0.219 36kg 2 4”(100mm) 5kg 13kg 229mm 6 0.229 0.229 0.315 43kg 3 5” (125mm) 7kg 14kg 254mm 6 0.254 0.254 0.387 56kg 4 6” (150mm) 9kg 19 kg 279.4mm 6 0.280 0.280 0.471 73kg 5 8”(200mm) 12kg 37kg 342.9 6 0.243 0.243 0.704 109kg 6 10” (250mm) 16kg 41 kg 406.9 6 0.407 0.407 0.994 137kg 7 12(300mm) 20Kg 45kg 482.6 6 0.483 0.483 1.400 165kg 8 14” ( 350mm) 6 0.534 0.534 1.709 9 16” (400mm) 6 0.597 0.597 2.1384 10 18” (450mm) 6 0.635 0.635 2.419 11 20” (500mm) 6 0.699 0.699 2.932 12 24”(600mm) 6 0.813 0.813 3.968 |

A Cement Feeding Rubber Hose is a specialized hose used in construction and industrial applications for the transportation of cement or other dry bulk materials. These hoses are typically designed to be durable, flexible, and resistant to wear and tear, making them suitable for heavy-duty tasks involving the transfer of abrasive substances like cement.

Key Features:- Material Composition: The hose is made from high-quality rubber, often reinforced with multiple layers of fabric or steel wire, ensuring both flexibility and strength.

- Abrasion Resistance: Cement is abrasive, and rubber hoses for this purpose are specially designed to resist damage caused by the roughness of the materials being pumped through them.

- Pressure Resistance: The hoses can withstand high pressures, as they are often used in applications where cement is pumped at high rates.

- Temperature Resistance: Some hoses are designed to endure the high temperatures associated with cement and concrete.

- Flexibility: The rubber construction ensures the hose can bend and move easily, making it suitable for various construction environments.

- Durability: Cement feeding rubber hoses are designed for heavy-duty use and can handle long-term use in tough environments.

- Concrete Pumping: Used to transport cement and concrete mixtures from a mixing site to construction areas.

- Cement Plants: For feeding raw cement materials or additives in production processes.

- Mining: Transporting cement or slurry for filling, binding, or other related activities.

These hoses are crucial for ensuring efficient and safe handling of cement in construction projects,

| Business Type | Manufacturer, Exporter |

| Country of Origin | India |

| Certification | ISO 9001:2008 |

| Usage | Industrial Use |

| Pressure | 10-15kg/cm2 |

| Shape | Round |

| Finishing | Coated |

| Material | PVC |

| Brand Name | SandhyaFlex |

| Product Code | Cement Feeding Rubber Hose |

| Port | Mumbai |

| Payment Terms | D/A |

| Delivery Time | 5-7Days |

| Packaging Details | Here are the complete **Packaging Details** for your **Sandhyaflex BackPVC Waterstopper**: --- ### **Packaging Details: Sandhyaflex BackPVC Waterstopper** * **Brand**: Sandhyaflex * **Product Type**: BackPVC Waterstopper * **Standard Roll Length**: 25 meters per roll * **Roll Widths Available**: 150mm, 230mm, 305mm (custom sizes available) * **Roll Thickness**: 6mm to 10mm (based on specification) --- #### **Packaging Specifications:** | Item | Description | | ------------------------------------ | ------------------------------------------------------------------------------------------ | | **Packaging Type** | Heavy-Duty HDPE Wrapping or Shrink-Wrapped Rolls | | **Protection** | Moisture-proof and dust-resistant packaging | | **Handling** | Rolls are strapped with plastic/nylon bands for lifting | | **Labeling** | Each roll carries branded labeling with size, batch no., production date, and company logo | | **Storage Instructions** | Store in a cool, dry place, away from direct sunlight and sharp objects | | **Shipping Units** | Rolls are palletized or bundled depending on order volume | | **Export Packaging (if applicable)** | Wooden crate/pallet with fumigation certificate (on request) | --- Would you like me to format this into a professional **catalog sheet or brochure section** with your company branding and logo? |

A cement feeding rubber hose is typically used in construction and industrial settings to transfer cement or other dry bulk materials from one location to another. These hoses are designed to withstand the abrasive nature of the materials they carry, such as cement, and are built with durable rubber compounds to handle high-pressure applications. Here are some key features and uses of cement feeding rubber hoses:

Key Features:

- Durability: The hoses are made from high-quality rubber materials that can resist wear and tear caused by the abrasive cement particles.

- Flexibility: These hoses are flexible, allowing for easier handling and maneuvering in tight spaces.

- Pressure Resistance: They are designed to withstand high-pressure systems that are commonly used for pumping cement.

- Abrasion Resistance: Cement is a coarse material, and the hose is reinforced to prevent damage caused by friction.

- Heat Resistance: Some hoses are also designed to resist the heat generated during the pumping process.

Common Uses:

- Concrete Pumping: Cement hoses are used to transfer cement from a mixer or truck to the desired location on a construction site.

- Grouting: These hoses are often employed for grouting purposes, where cement is injected into gaps or cavities for stabilization.

- Industrial Bulk Transfer: In some industries, these hoses are used to transfer other dry bulk materials.

| Business Type | Manufacturer, Exporter, Supplier |

| Usage | Industrial Use |

| Pressure | 10-15kgs |

| Finishing | Coated |

| Material | Rubber |

| Shape | Spiral |

| Working Pressure | 10-25 Bar |

| Size/Diameter | 4"inch |

| Unit Length | 6m |

| Layers | 2 to 8 Layers |

| Wall Thickness | 15 to 20mm |

| Product Code | Cement Feeding Rubber Hose |

| Port | Mumbai |

| Payment Terms | D/A |

| Delivery Time | 5-7days |

\\n

A slurry rubber hose is a type of hose specifically designed to transport abrasive and thick fluids, known as slurries, in industries like mining, construction, or wastewater treatment. Slurries typically consist of a mixture of water and solid particles, such as sand, gravel, or other sediments.

\\nFeatures of Slurry Rubber Hoses:- \\n

- \\n

Durability: These hoses are made from high-quality rubber compounds that provide excellent resistance to abrasion, wear, and impact. This makes them ideal for moving slurries, which can be harsh and abrasive.

\\n \\n - \\n

Flexibility: Slurry rubber hoses maintain flexibility even under harsh working conditions, allowing for easy installation and movement in tight spaces.

\\n \\n - \\n

High Pressure Resistance: Slurry hoses are designed to withstand high-pressure environments, which is crucial in many slurry transfer applications.

\\n \\n - \\n

Reinforced Construction: They often have multiple layers of reinforcement, such as fabric or steel wire, to enhance strength and prevent collapse under pressure.

\\n \\n - \\n

Chemical Resistance: Depending on the materials used in the hose, slurry rubber hoses can be resistant to a wide range of chemicals that may be present in the slurry mix.

\\n \\n

- \\n

- Mining and Mineral Processing: Transporting minerals, ores, and other solids suspended in water. \\n

- Construction: Pumping concrete or other thick mixtures. \\n

- Wastewater Treatment: Moving slurry-like waste materials in various stages of treatment. \\n

- Agriculture: Transporting slurry materials like manure or liquid fertilizers. \\n

Would you like more specific information on a certain type or manufacturer of slurry rubber hoses?

\\n| Business Type | Manufacturer, Exporter, Supplier |

| Usage | Industrial Use |

| Pressure | 10-15kgs |

| Brand Name | sandhyaflex |

| Material | Rubber |

| Finishing | Polished |

| Shape | Round |

| Hardness | 55 To 60 Shore A |

| Unit Length | 3-15 m |

| Temperature | -10 to 100 Degree C |

| Thickness | 12 to 15mm |

| Weight | 120kg/Mtr |

| I Deal In | New Only |

| Product Code | Cement Feeding Rubber Hose |

| Port | Mumbai |

| Payment Terms | D/A |

| Delivery Time | 5-7days |

\\n

A slurry rubber hose is a type of hose specifically designed to transport abrasive and thick fluids, known as slurries, in industries like mining, construction, or wastewater treatment. Slurries typically consist of a mixture of water and solid particles, such as sand, gravel, or other sediments.

\\nFeatures of Slurry Rubber Hoses:- \\n

- \\n

Durability: These hoses are made from high-quality rubber compounds that provide excellent resistance to abrasion, wear, and impact. This makes them ideal for moving slurries, which can be harsh and abrasive.

\\n \\n - \\n

Flexibility: Slurry rubber hoses maintain flexibility even under harsh working conditions, allowing for easy installation and movement in tight spaces.

\\n \\n - \\n

High Pressure Resistance: Slurry hoses are designed to withstand high-pressure environments, which is crucial in many slurry transfer applications.

\\n \\n - \\n

Reinforced Construction: They often have multiple layers of reinforcement, such as fabric or steel wire, to enhance strength and prevent collapse under pressure.

\\n \\n - \\n

Chemical Resistance: Depending on the materials used in the hose, slurry rubber hoses can be resistant to a wide range of chemicals that may be present in the slurry mix.

\\n \\n

- \\n

- Mining and Mineral Processing: Transporting minerals, ores, and other solids suspended in water. \\n

- Construction: Pumping concrete or other thick mixtures. \\n

- Wastewater Treatment: Moving slurry-like waste materials in various stages of treatment. \\n

- Agriculture: Transporting slurry materials like manure or liquid fertilizers. \\n

Would you like more specific information on a certain type or manufacturer of slurry rubber hoses?

\\n