-

sandhyaprises@gmail.com -

View Mobile Number

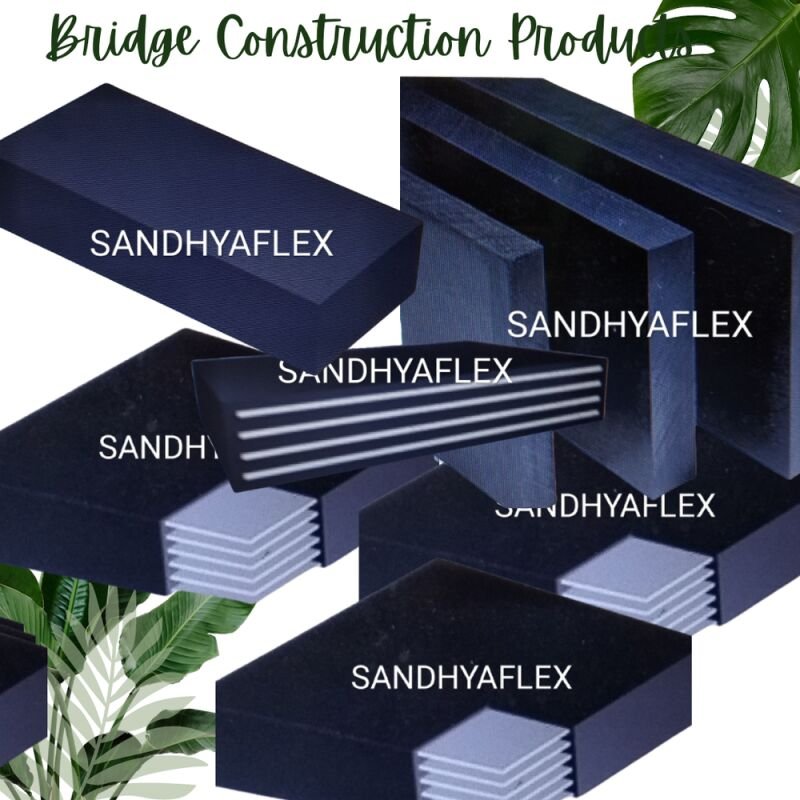

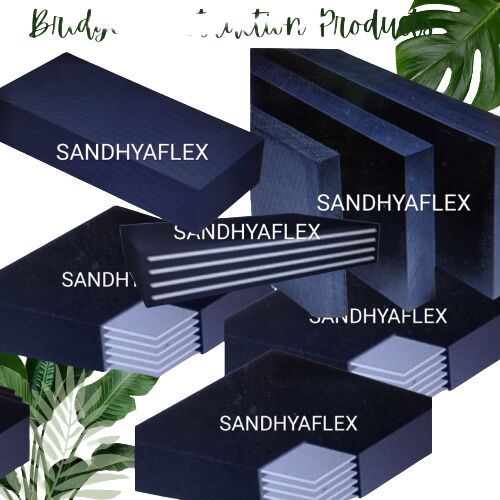

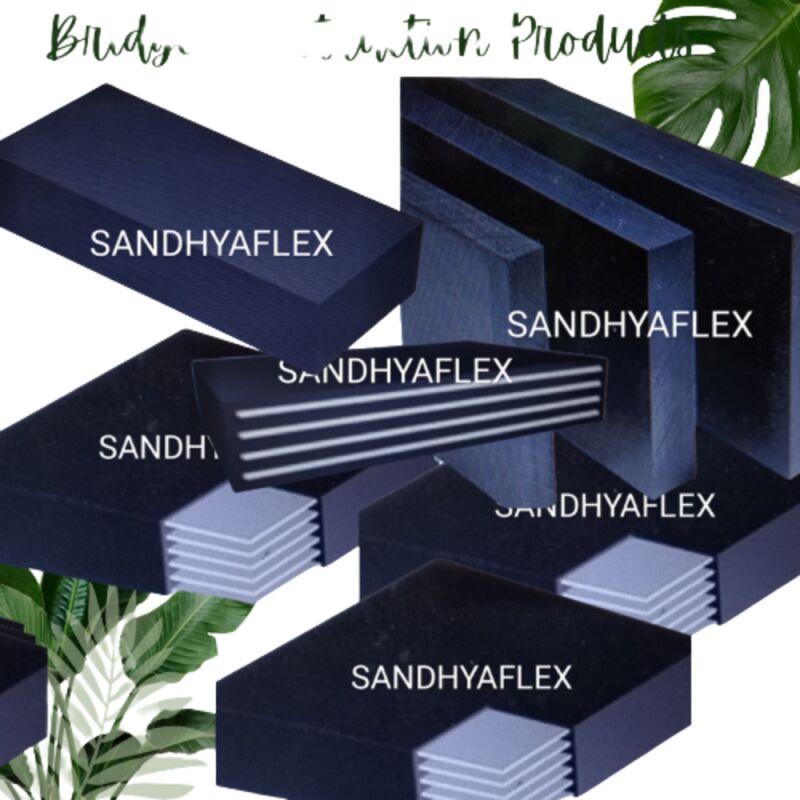

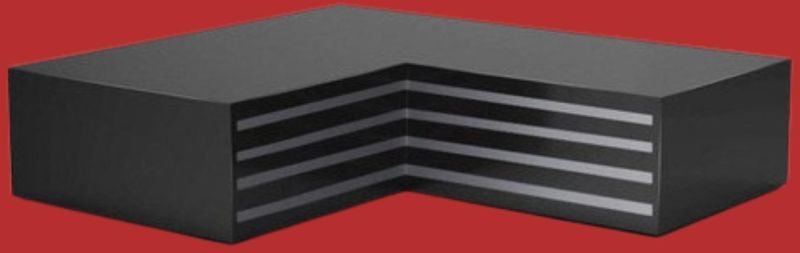

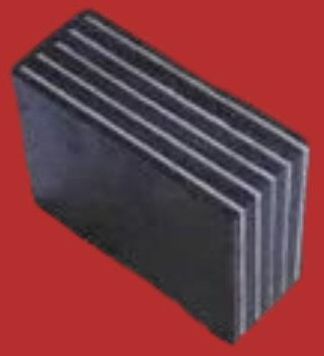

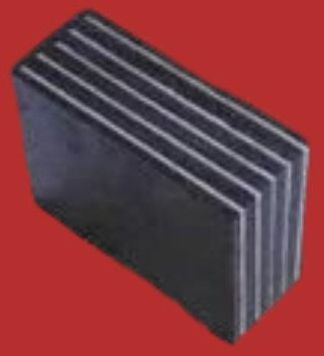

Elastomeric Bridge Bearing

Leading Manufacturers, Exporters, Wholesaler, Retailer of 500x320x80mm Elastomeric Bridge Bearings, Neoprene Bridge Bearing, Neoprene Elastomeric Bridge Bearing and Sandhyaflex Laminated Elatomeric Bridge Bearing from Hyderabad.

| Business Type | Manufacturer, Supplier, Retailer |

| Brand Name | SANDHYAFLEX |

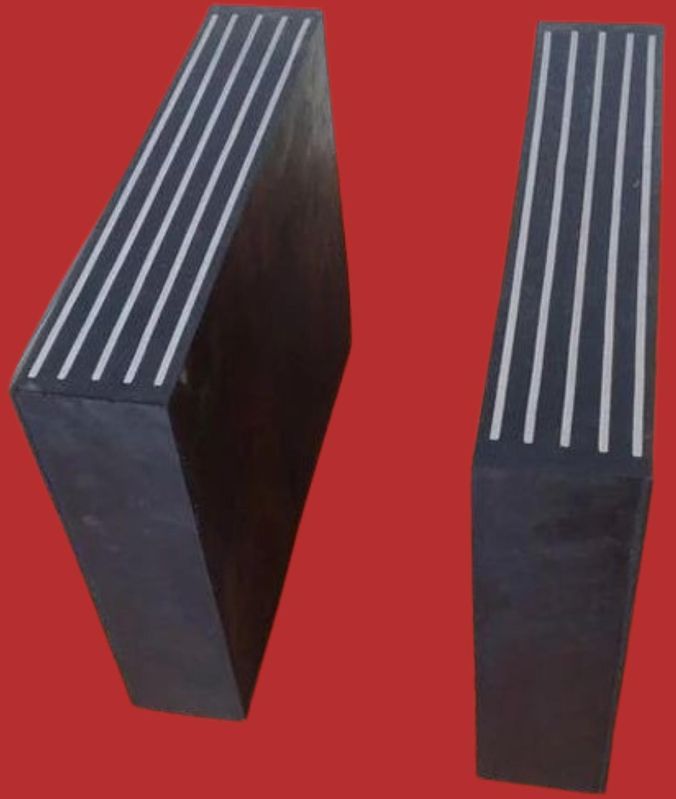

| Material | Neoprene Rubber, Rubber With MS Plate |

| Color | Black |

| Type | Elastomeric Bearing Pad |

| Thickness | 22 Ot 144mm |

| Size | 22mm Thick To 144mm Thick |

| Product Code | EBB |

| Port | mumbai |

| Payment Terms | L/C |

| Delivery Time | 7 to 15 days |

Sandhya enterprises plot no 5-24-122351, ambedkar nagar, gajuramaram, r.r. Dist.500055, hyderabad,telangana state. we are pleased to introduce ourselves as rubber sheet, textile braided hose, rubber suction hose, elastomeric bridge bearing, rubber moulded products, extruded products and pvc water stop, bridge expansion joint. We have leading and reputed consumer as our valued customers. It will be our pleasure if we can be of any service to your good selves and welcome your inquiries for your requirements. Our service is well established with the, cement industries, granites industries, electric power industries, ready mix industries, construction company and civil construction works. We go through the test certificate, physical properties, processing condition of the finished goods, grades etc and after looking at the final product we confidently recommended our valued customer to buy the product. Plot no 5-24-122351, ambedkar nagar, gajuramaram, r.r. Dist.500055,hyderabad telangana state. India email id: sandhyaprises@gmail.com, web:www.sandhyaprises.in contact no:+91-9652998932 ,9550921831 sandhya enterprises elastic moduluse test 10mpa to 20mpa ultimate compression strength 60mpa adhesion strength (stripping test) at 4mpa vl and 3mpa hl shear modulus test 5mpa vl and hl load 2h plot no 5-24-122351, ambedkar nagar, gajuramaram, r.r. Dist.500055,hyderabad telangana state. technical details sr no. Test unit specification and testing method specimens 1 hardness irhd is: 3400 (part ii) cl.5.1.2.2 4.0mm (min ) thickness of test specimen 2 tensile strength mpa is:3400 ( part i) table 1 type -1 thick- 2.0 +.0.20mm width 6.0 + 0.40mm bench mark-25.0mm (max) 3 elongation at break % 4 adhesion strength (metal to rubber knm is:3400 ( part xiv) cl.3.3 length -125mm width-25mm 5 ash content % is:3400 (part xxii) cl. A-8.3.1 is 1 g (min) 6 polymer idenAn elastomeric bridge bearing is a specialized component used in bridge construction and infrastructure projects. It is designed to provide support, flexibility, and load transfer between the bridge superstructure and substructure while accommodating movements caused by thermal expansion, contraction, and other factors. The packing details of elastomeric bridge bearings may vary depending on the manufacturer and supplier. However, here are some general considerations: 1. Quantity: The packaging should indicate the number of elastomeric bridge bearings included in a single pack. It can range from one bearing to multiple bearings, depending on the packaging configuration and supplier's specifications. 2. Size and Dimensions: The packaging may specify the size and dimensions of the elastomeric bridge bearing. This information helps determine if the bearing is suitable for the intended application and the bridge design requirements. 3. Material: The packaging may mention the specific elastomeric material used for the bearing construction. Elastomeric bridge bearings are typically made from high-quality synthetic rubber compounds that offer excellent durability, resilience, and load-bearing capacity. 4. Design and Load Capacity: The packaging may provide information about the design type and load capacity of the elastomeric bridge bearing. This includes details such as the maximum vertical load, horizontal load, rotational capacity, and allowable displacements. 5. Surface Treatment: The packaging may indicate if the elastomeric bridge bearings have any specific surface treatment, such as an anti-slip or corrosion-resistant coating. These treatments can enhance the performance and longevity of the bearings. 6. Packaging Material: The packaging itself may be mentioned, indicating the type of material used, such as cardboard boxes or crates. The packaging should provide sufficient protection to prevent damage during transportation and storage. 7. Installation Instructions: The packaging may include installation instructions or guidelines, describing the proper installation methods and

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Brand Name | SANDHYAFLEX |

| Material | Rubber With MS Plate |

| Certification | ISO 9001:2008 Certified |

| Hardness | 60 Shore A |

| Number Of Flower | Elastomeric Bridge Bearings |

| Tensile Strength | 17MPa |

| Country of Origin | India |

| Size | 160mm To 1500mm Lenght |

| Elastomeric Bridge Baring | 0.34 to 0.40ccm |

| Elastomeric Bridge Bearing | 0.34 to 0.40/ccm |

| Product Code | NEBB |

| Port | kakinada |

| Payment Terms | T/T |

| Delivery Time | 7 to 15days |

| Packaging Details | Packing with HDPE cover |

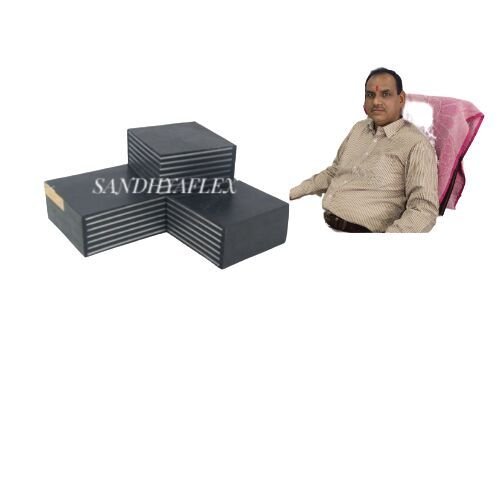

sandhya enterprises is a manufacturer and supplierof bridge bearing pad as per morth, irc 83 (part ii) 1987 and uic 772 2r. thickness 25mm to 144mm we are pleased to introduce ourselves as rubber sheet, textile braided hose, rubber suction hose, elastomeric bridge bearing, rubber moulded products, extruded products and pvc water stop, bridge expansion joint. We have leading and reputed consumer as our valued customers. It will be our pleasure if we can be of any service to your good selves and welcome your inquiries for your requirements. our service is well established with the, cement industries, granites industries, electric power industries, ready mix industries, construction company and civil construction works. We go through the test certificate, physical properties, processing condition of the finished goods, grades etc and after looking at the final product we confidently recommended our valued customer to buy the product. ultimate compression strength 60mpa adhesion strength (stripping test) at 4mpa vl and 3mpa hl shear modulus test 5mpa vl and hl load 2h technical details sr no. Test unit specification and testing method specimens 1 hardness irhd is: 3400 (part ii) cl.5.1.2.2 4.0mm (min ) thickness of test specimen 2 tensile strength mpa is:3400 ( part i) table 1 type -1 thick- 2.0 +.0.20mm width 6.0 + 0.40mm bench mark-25.0mm (max) 3 elongation at break % 4 adhesion strength (metal to rubber kn/m is:3400 ( part xiv) cl.3.3 length -125mm width-25mm 5 ash content % is:3400 (part xxii) cl. A-8.3.1 is 1 g (min) 6 polymer identification chemically 0.5 g (min) 7 percentage of polymers % 1 g (min) 8 compression set % is: 3400 (part x) cl. 5.1 thick -12.5 + 0.50mm dia-29 + 0.50mm 9 elastic modulus mpa irc 83 (part ii) 1987, uic 772 -2r and morth 2 nos from finish product 10 shear modulus mpa 11 ultimate compression strength mpa one specimen size of 100x200mm (cutting piece from An elastomeric bridge bearing, also known as a rubber bridge bearing, is a structural component used to support and accommodate movement in bridge structures. It is designed to transfer loads from the superstructure (the bridge deck and its components) to the substructure (piers, abutments, or supports) while allowing for various types of movement, such as rotation, translation, and rotation in multiple axes. Elastomeric bridge bearings are typically made of layers of elastomeric material, such as natural rubber or synthetic rubber compounds. The rubber layers are often reinforced with steel plates or fabric inserts to provide additional strength and stability. The combination of rubber and reinforcement allows the bearing to withstand the applied loads and movements while providing flexibility and resilience. The main functions of elastomeric bridge bearings are: 1. Load transfer: Elastomeric bearings distribute the weight and loads from the bridge superstructure to the substructure, reducing the stress on the bridge components and foundations. 2. Movement accommodation: They accommodate various types of bridge movements, including expansion and contraction due to temperature changes, horizontal and vertical displacements caused by live loads or settlement, and rotational movements due to bridge deck rotations or seismic events. 3. Vibration and shock absorption: Elastomeric materials have inherent damping properties, which help absorb and dissipate vibrations and shocks, improving the overall structural performance and comfort of the bridge. 4. Noise reduction: The rubber material helps to dampen and reduce noise generated by traffic or other sources, resulting in quieter bridge operations. Elastomeric bridge bearings are available in different types and designs, depending on the specific application and load requirements. Common types include pot bearings, spherical bearings, and strip bearings, each with their own characteristics and advantages. Proper installation and maintenance of elastomeric bridge bearings are crucial for

| Business Type | Manufacturer, Exporter, Supplier |

| Color | Black |

| Thickness | 25-144 Mm |

| Tensile Strength | 17.0MPa |

| Number of Row | Single Row |

| Specialities | Shear Strength, Precise Design |

| Packaging Type | Carton Box |

| Length | 200-1500 mm |

The Sandhyaflex Laminated Elastomeric Bridge Bearing is a specialized bearing component used in bridge construction to provide support, distribute loads, and accommodate movements such as thermal expansion, contraction, and settlement. It is designed to absorb forces from traffic loads, weather changes, and vibrations, ensuring the stability and longevity of bridges and other structures.

Key Features:-

Laminated Construction:

- The bearing consists of multiple layers or laminates of elastomeric (rubber-based) materials, which are bonded together with steel plates. This laminated design helps to distribute loads evenly and provides flexibility to handle vertical and horizontal movements.

- Elastomeric materials are chosen for their high compressive strength, durability, and flexibility, making them ideal for dynamic loads and structural movement.

-

Load Distribution and Flexibility:

- These bearings help in transferring loads from the superstructure (like a bridge deck) to the substructure (like the foundation or piers) while allowing for movement.

- They accommodate vertical and horizontal displacements, as well as angular rotations caused by traffic, thermal expansion, or settlement.

-

Resistance to Environmental Factors:

- Elastomeric materials are resistant to weathering, UV rays, chemicals, and ozone, ensuring the bearing's longevity in outdoor environments, even under harsh conditions.

- They are also resistant to water, oil, and fuel exposure, which helps in protecting the bridge structure in challenging climates.

-

Durability:

- Laminated elastomeric bearings are designed to last for long periods, reducing maintenance requirements and contributing to the overall longevity of the bridge.

- Their ability to absorb shocks and vibrations helps prevent damage to the bridge structure from repeated traffic loads or seismic activities.

-

Applications:

- Bridge construction: To support the weight of the bridge and allow for safe and efficient movement.

- Viaducts and flyovers: For similar load-bearing and movement accommodation in overpasses.

- Marine and road infrastructure: In areas that experience heavy traffic and harsh weather conditions.

-

Cost-Effectiveness:

- Compared to other bearing types, laminated elastomeric bearings are relatively cost-effective and provide a good balance between performance, maintenance, and longevity.

- High load-bearing capacity: Suitable for heavy traffic and long-span bridges.

- Accommodates movement: Ideal for structures subjected to thermal expansion, contraction, and settlement.

- Durability and weather resistance: Designed to last in tough environmental conditions.

- Reduces maintenance: The long lifespan reduces the need for frequent repairs or replacements.

These bearings are a crucial component in ensuring the safety, stability, and longevity of bridges and related infrastructure. Would you like more information on the installation process or a comparison to other types of bearings used in bridge construction?