-

sandhyaprises@gmail.com -

View Mobile Number

| Business Type | Manufacturer, Exporter, Supplier |

| Length | 25-30mtr |

| Size | 150x8mm |

| Application | Construction |

| Click to view more | |

Product Details

Dimension in CBM

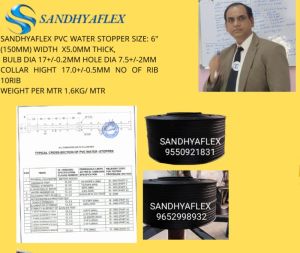

PVC Water Stopper with Center Bulb

Each Roll 25Mtr

SR No Dimension Length Width Height CBM Weight kg/Roll

1 150x5mm 0.625 0.625 0.150 0.059 40

2 150x6mm 0.625 0.625 0.150 0.059 45

3 150x8mm 0.625 0.625 0.150 0.059 55

4 200x8mm 0.625 0.625 0.200 0.059 70

5 200x10mm 0.65 0.65 0.200 0.078 80

6 225x5mm 0.625 0.625 0.23 0.090 65

7 225x6mm 0.625 0.625 0.230 0.090 70

8 225x8mm 0.65 0.65 0.230 0.097 90

9 225x10mm 0.65 0.65 0.230 0.097 100

10 240x8mm 0.65 0.650 0.240 0.104 110

11 240x10mm 0.650 0.650 0.240 0.104 125

12 250x8mm 0.675 0.675 0.250 0.114 95

s13 250x10mm 0.675 0.675 0.250 0.114 115

14 300x6mm 0.700 0.700 0.300 0.147 95

15 300x8mm 0.725 0..725 0.300 0.158 115

16 300x10mm 0.750 0.750 0.300 0.169 145

17 300x12mm 0.775 0.775 0.300 0.18 140

18 300x15mm 0.800 0.800 0.300 0.192 160

Kiker Type

19 230x4mm 0.625 0.625 0.230 0.090 67

Dumbbell Type

20 230x8mm 0.650 0.650 0.230 0.097 87

21 230x10mm 0.650 0.650 0.230 0.097 100

PVC water stoppers, often used in construction projects like dams, tunnels, and foundations, are essential for preventing the passage of water through joints in concrete structures. To improve their effectiveness and durability, the surface treatment of PVC water stoppers is crucial.

Common surface treatments for PVC water stoppers include:

-

UV Protection Coating: PVC is susceptible to degradation from ultraviolet (UV) rays, so applying a UV-resistant coating helps prolong the material's lifespan when exposed to sunlight. This treatment also ensures that the water stopper maintains its strength and flexibility over time.

-

Surface Polishing: Polishing the surface can improve the adhesion of the water stopper to concrete. It smooths out imperfections, ensuring that the stopper forms a tight seal and reduces the risk of water leakage.

-

Heat Stabilization: PVC material can degrade when exposed to high temperatures. Surface heat treatment processes can stabilize the material to enhance its performance in varying temperature conditions. This treatment also increases its resistance to thermal aging.

-

Antifungal and Antibacterial Coatings: These treatments help prevent microbial growth on the surface of the PVC water stopper, which can occur due to moisture exposure. The application of antimicrobial coatings ensures a cleaner surface and prolongs its usability in harsh, wet conditions.

-

Chemical Resistance Treatment: If the water stopper is exposed to aggressive chemicals or extreme environmental conditions, surface treatments may involve applying chemical-resistant coatings to protect the material from degradation.

-

Textured Surface Treatment: Sometimes, a textured or roughened surface is applied to improve bonding between the PVC water stopper and the surrounding concrete. This is particularly important for ensuring that the stopper remains securely in place during the setting of the concrete.