-

sandhyaprises@gmail.com -

View Mobile Number

| Business Type | Manufacturer, Exporter |

| Material | Pvc |

| Color | Black, White |

| Condition | New |

| Click to view more | |

Product Details

Application

Construction

Length

25-30mtr

Feature

High Strength

Pattern

Ribbed

Dimension

200-250mm

Product Code

PVC Water Stopper

Port

Mumbai

Delivery Time

Immidiate

Packaging Details

Export Packing

Dimension in CBM

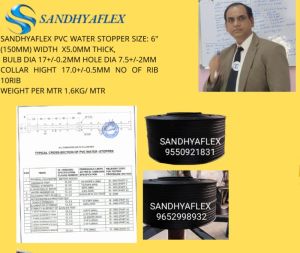

PVC Water Stopper with Center Bulb

Each Roll 25Mtr

SR No Dimension Length Width Height CBM Weight kg/Roll

1 150x5mm 0.625 0.625 0.150 0.059 40

2 150x6mm 0.625 0.625 0.150 0.059 45

3 150x8mm 0.625 0.625 0.150 0.059 55

4 200x8mm 0.625 0.625 0.200 0.059 70

5 200x10mm 0.65 0.65 0.200 0.078 80

6 225x5mm 0.625 0.625 0.23 0.090 65

7 225x6mm 0.625 0.625 0.230 0.090 70

8 225x8mm 0.65 0.65 0.230 0.097 90

9 225x10mm 0.65 0.65 0.230 0.097 100

10 240x8mm 0.65 0.650 0.240 0.104 110

11 240x10mm 0.650 0.650 0.240 0.104 125

12 250x8mm 0.675 0.675 0.250 0.114 95

s13 250x10mm 0.675 0.675 0.250 0.114 115

14 300x6mm 0.700 0.700 0.300 0.147 95

15 300x8mm 0.725 0..725 0.300 0.158 115

16 300x10mm 0.750 0.750 0.300 0.169 145

17 300x12mm 0.775 0.775 0.300 0.18 140

18 300x15mm 0.800 0.800 0.300 0.192 160

Kiker Type

19 230x4mm 0.625 0.625 0.230 0.090 67

Dumbbell Type

20 230x8mm 0.650 0.650 0.230 0.097 87

21 230x10mm 0.650 0.650 0.230 0.097 100

Dimension in CBM

PVC Water Stopper with Center Bulb

Each Roll 25Mtr

SR No Dimension Length Width Height CBM Weight kg/Roll

1 150x5mm 0.625 0.625 0.150 0.059 40

2 150x6mm 0.625 0.625 0.150 0.059 45

3 150x8mm 0.625 0.625 0.150 0.059 55

4 200x8mm 0.625 0.625 0.200 0.059 70

5 200x10mm 0.65 0.65 0.200 0.078 80

6 225x5mm 0.625 0.625 0.23 0.090 65

7 225x6mm 0.625 0.625 0.230 0.090 70

8 225x8mm 0.65 0.65 0.230 0.097 90

9 225x10mm 0.65 0.65 0.230 0.097 100

10 240x8mm 0.65 0.650 0.240 0.104 110

11 240x10mm 0.650 0.650 0.240 0.104 125

12 250x8mm 0.675 0.675 0.250 0.114 95

s13 250x10mm 0.675 0.675 0.250 0.114 115

14 300x6mm 0.700 0.700 0.300 0.147 95

15 300x8mm 0.725 0..725 0.300 0.158 115

16 300x10mm 0.750 0.750 0.300 0.169 145

17 300x12mm 0.775 0.775 0.300 0.18 140

18 300x15mm 0.800 0.800 0.300 0.192 160

Kiker Type

19 230x4mm 0.625 0.625 0.230 0.090 67

Dumbbell Type

20 230x8mm 0.650 0.650 0.230 0.097 87

21 230x10mm 0.650 0.650 0.230 0.097 100

A PVC water stopper is a construction material commonly used in concrete structures to prevent the passage of water through construction joints, expansion joints, and other openings. It's typically made of high-quality polyvinyl chloride (PVC) and is used to ensure a waterproof seal in various applications, including basements, tunnels, reservoirs, swimming pools, and water treatment plants.

Key Features of PVC Water Stoppers:- Waterproofing: The main function is to prevent water from seeping through joints in concrete structures.

- Durability: Resistant to chemical attack, corrosion, and degradation over time, making it ideal for long-lasting applications.

- Flexibility: PVC water stoppers are flexible and can expand or contract to accommodate joint movements.

- Ease of Installation: They are relatively easy to install during the construction phase, as they can be embedded in the concrete joints.

- Variety of Designs: Available in different shapes and sizes to suit specific joint configurations (e.g., straight, L-shaped, or T-shaped).

- Cost-effective: PVC is relatively affordable, providing an economical solution for waterproofing needs.

- Foundation and basement walls: To prevent water ingress in subterranean structures.

- Water tanks and reservoirs: To maintain water-tightness.

- Bridge decks and tunnels: To protect against water penetration.

- Swimming pools: To ensure a durable water seal.

- Placement: It is installed in the construction joint or where two concrete surfaces meet.

- Positioning: Careful positioning within the formwork is crucial for ensuring its effectiveness.

- Sealing: After concrete is poured, the water stopper should be carefully checked to ensure there are no gaps or defects.

Overall, PVC water stoppers are a reliable and efficient solution for preventing water damage in concrete structures exposed to water or moisture.

Looking for "9" Water Stopper" ?

Mtr