-

sandhyaprises@gmail.com -

View Mobile Number

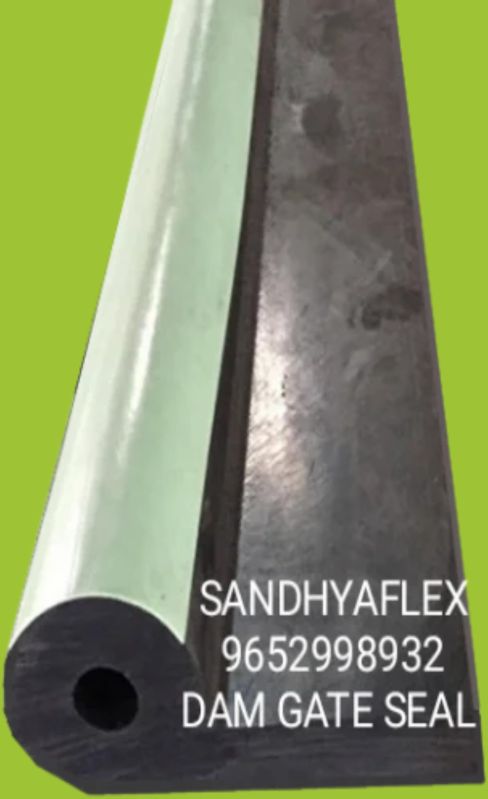

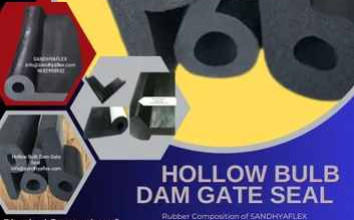

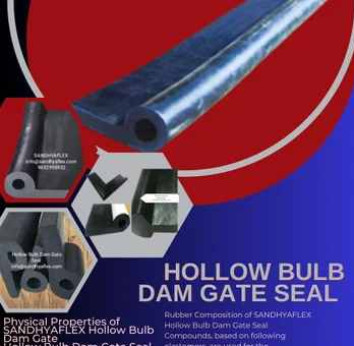

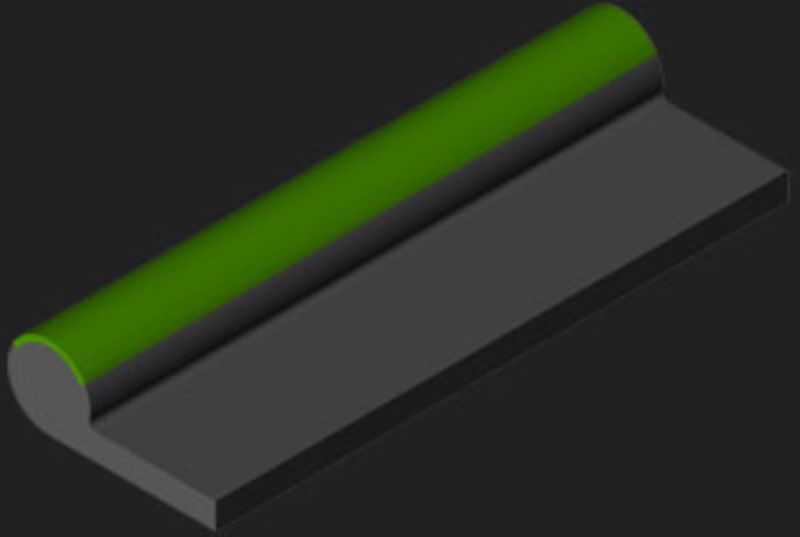

Dam Gate Seal

Leading Manufacturers, Exporters, Wholesaler, Retailer of 11855 Hollow Bulb Dam Gate Seal, 22mm Bull Dia Hollow Bulb Dam Gate Seal, Bull Dia Hollow Bulb Dam Gate Seal, Hollow Bulb Dam Gate Seal, PTFE Cladded Dam Rubber Seal, PTFE Cladding Corner Dam Gate Seal, Sandhyaflex Dam Gate Seal, Sandhyaflex P/J Type Musical Note Dam Gate Seal, Stem Thickness Hollow Bulb Dam Gate Seal, Teflon Cadded Hollow Bulb Dam Gate Seal, Z Type Dam Gate Rubber Seal and Z Type Musical Note Dam Gate Seal from Hyderabad.

| Business Type | Manufacturer, Exporter, Supplier |

| Tensile Strength | 14 |

| Steam Thickness | 19mm |

| Color | Black |

| Size (Inches) | 15x160x19mm |

| Country of Origin | India |

| Diameter | 45 |

| Temperature Range | 70 deg C |

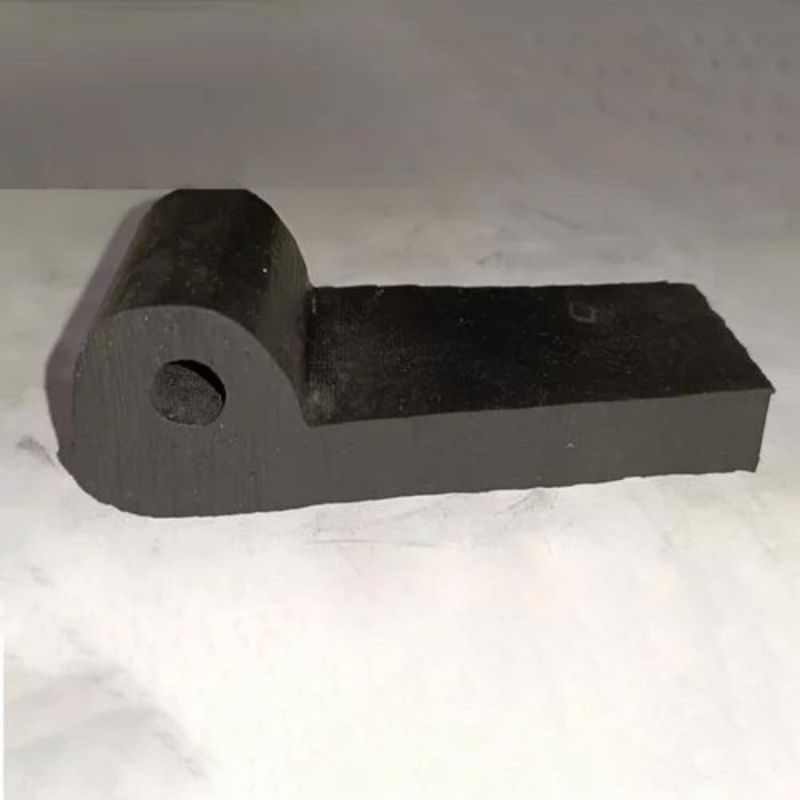

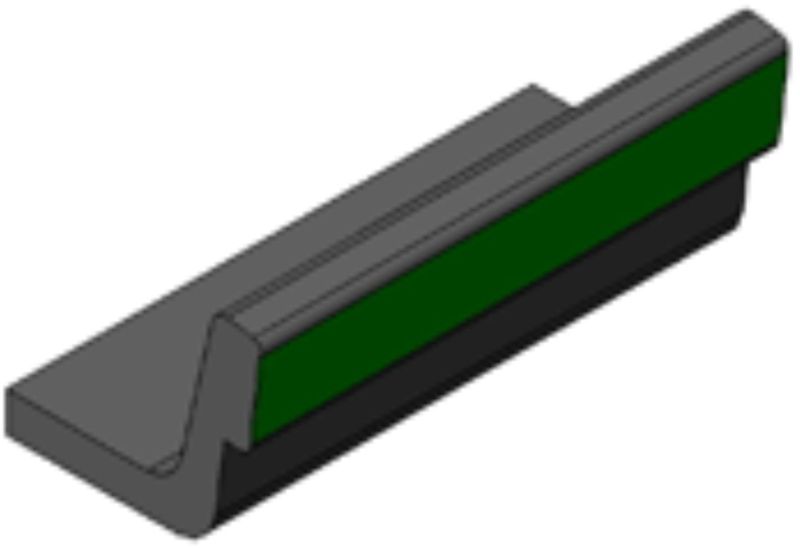

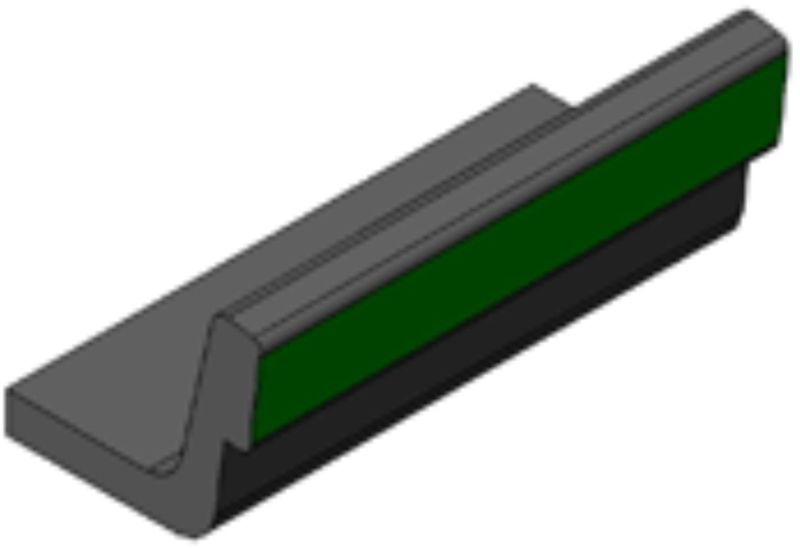

The **11855 Hollow Bulb Dam Gate Seal** refers to a specific model or type of hollow bulb seal used in dam gates and other hydraulic structures. The number "11855" likely indicates a particular design specification, part number, or standard reference for the seal. These seals are critical components in ensuring that dam gates function effectively by preventing water leakage when the gates are closed.

### Key Features of the 11855 Hollow Bulb Dam Gate Seal:

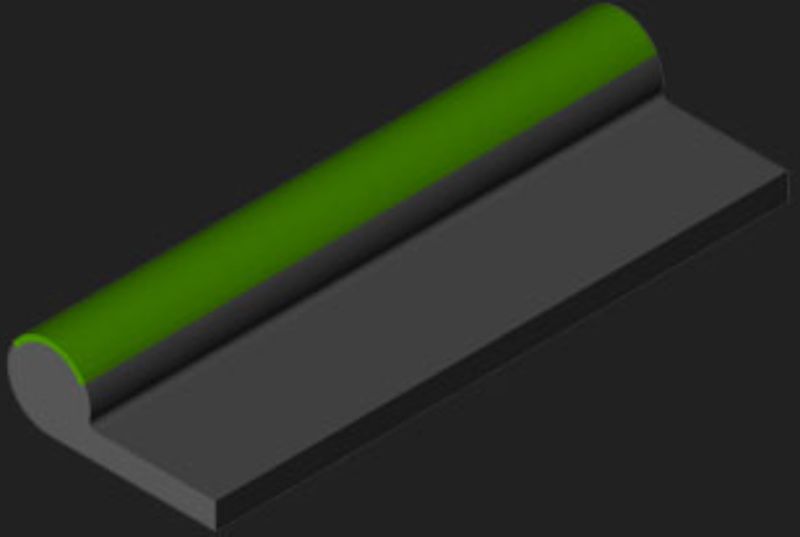

1. **Hollow Bulb Design**: - The "hollow bulb" refers to the shape of the seal, which typically features a hollow, cylindrical section that compresses under pressure to form a watertight seal. - This design allows the seal to adapt to the gate's surface and any irregularities, ensuring a consistent seal even under varying pressure conditions.

2. **Size and Specifications**: - The specific dimensions and properties of the "11855" model would be defined by the manufacturer or the standard it adheres to. These details would include the diameter of the bulb, the thickness of the seal, and other critical measurements that dictate its suitability for specific applications. - If "11855" is a reference number, it could include details such as the material composition, maximum pressure handling, and recommended usage scenarios.

3. **Material**: - Hollow bulb seals like the 11855 model are typically made from durable elastomeric materials, such as EPDM rubber, neoprene, or other synthetic rubbers. These materials are chosen for their flexibility, durability, and resistance to environmental factors such as UV light, water, and temperature extremes. - The choice of material ensures that the seal can maintain its integrity over time, even under continuous exposure to water and varying pressure conditions.

4. **Applications**: - The 11855 Hollow Bulb Dam Gate Seal is used in a variety of hydraulic structures, including spillway gates, sluice gates, and radial gates. Its design is intended to provide a reliable seal that prevents water from leaking past the gate when it is in the closed position. - It is particularly suitable for situations where a robust, flexible seal is required to maintain the integrity of the dam structure.

5. **Performance**: - The hollow bulb design allows the seal to compress and expand as needed, creating a tight seal that can handle fluctuations in water pressure and movement of the gate. - The specific model 11855 would have performance characteristics tailored to the needs of the particular dam or hydraulic system, such as the ability to withstand high pressure, resist wear and tear, and provide long-term sealing capability.

6. **Installation and Maintenance**: - Proper installation is crucial for the seal to function correctly. The seal must be aligned and positioned so that it compresses fully when the gate is closed, ensuring a watertight seal. - Regular maintenance, including inspections for wear or damage, is necessary to ensure the seal continues to perform effectively. Over time, the seal may need to be replaced if it shows signs of degradation.

### Benefits:

- **Effective Sealing**: The hollow bulb design provides a reliable seal that can adapt to the gate's surface, preventing water from leaking through.- **Durability**: Constructed from high-quality materials, the 11855 seal is designed to withstand the harsh environmental conditions typically found in dam operations.- **Flexibility**: The seal's ability to compress and expand allows it to maintain a consistent seal even when the gate or surrounding structure shifts or experiences pressure changes.

### Summary:

| Business Type | Manufacturer, Exporter, Supplier |

| Steam Thickness | 16mm |

| Color | Black |

| Size (Inches) | 45Bulb Dia X 22mm Holes Dai |

| Country of Origin | India |

| Diameter | 160mmx 16mm |

| Thickness | 10-20 mm |

| Temperature | -10 to 80 Deg C |

| Packaging Size | SANDHYAFLEX Bulb Seal/ Side Seal 1 Size25Diax 70x10mm Bulb Seal Size: Bulb Dia. 33mm |

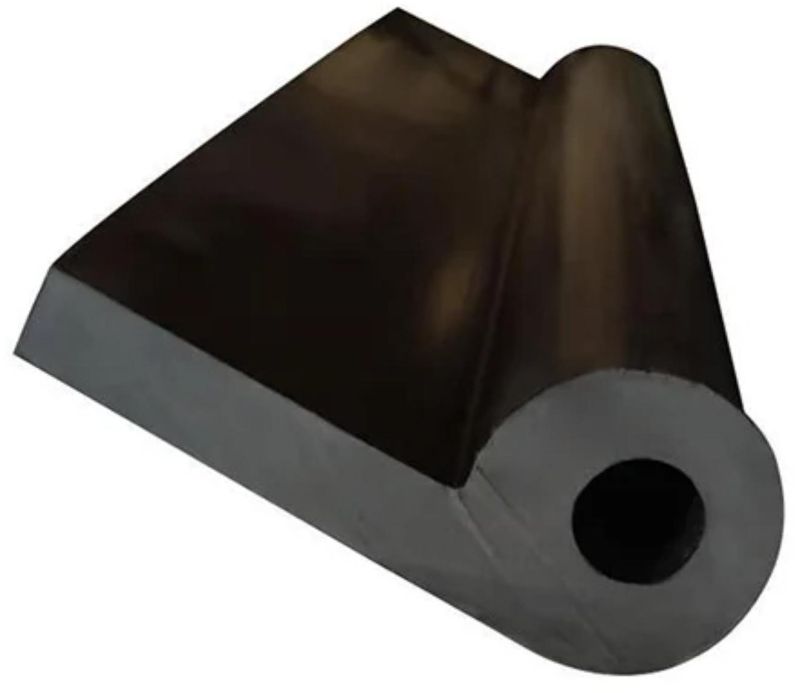

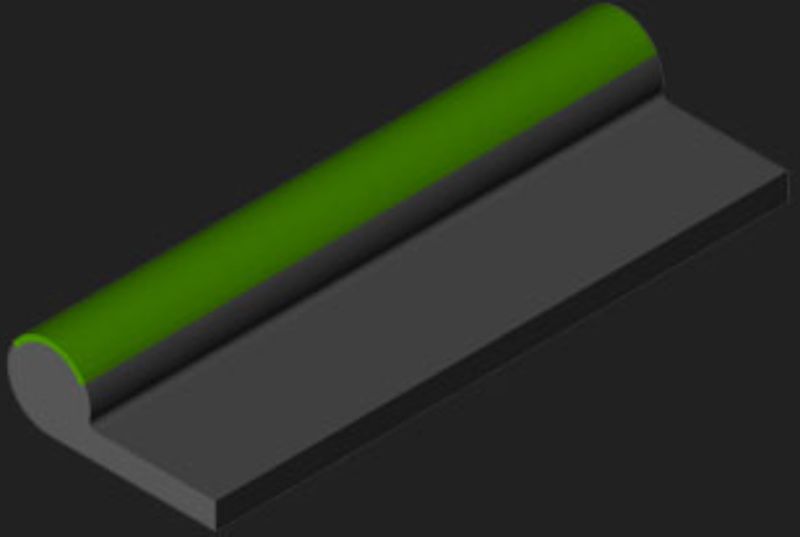

A **22mm Bull Dia Hollow Bulb Dam Gate Seal** refers to a specific type of hollow bulb seal used in dam gates, where the "22mm Bull Dia" specifies the diameter of the "bulb" or the hollow section of the seal. The term "Bull Dia" likely refers to the diameter of the central, bulbous part of the seal that compresses to form the watertight barrier when the dam gate is closed.

### Key Features of a 22mm Bull Dia Hollow Bulb Dam Gate Seal:

1. **22mm Diameter**: - The "22mm Bull Dia" indicates that the diameter of the hollow bulb portion of the seal is 22 millimeters. This dimension is crucial as it determines the seal's ability to compress and expand, affecting its sealing efficiency and suitability for different gate sizes and pressures.

2. **Hollow Bulb Design**: - The seal has a hollow, cylindrical section that allows it to compress under pressure, creating a watertight seal between the dam gate and its frame. The hollow design is essential for flexibility, enabling the seal to conform to the gate's surface and any irregularities.

3. **Material**: - Typically made from durable elastomeric materials such as rubber, these seals are designed to withstand significant environmental stress, including water pressure, temperature variations, and exposure to UV radiation. - The material must be resilient enough to maintain its shape and sealing properties over time, even under repeated compression.

4. **Application**: - This type of seal is used in various dam gate applications, such as spillway gates, sluice gates, and radial gates. The 22mm diameter makes it suitable for gates that require a moderate level of sealing force, where the gate needs to operate smoothly without excessive resistance. - The specific diameter may be chosen based on the gate's size, the pressure exerted by the water, and the specific sealing requirements.

5. **Performance**: - A 22mm diameter is relatively small, which means the seal is likely used in applications where space is limited or where a smaller sealing force is sufficient. Despite its smaller size, it must still provide a reliable seal to prevent water leakage. - The hollow bulb design ensures that the seal can accommodate slight misalignments or movements of the gate, maintaining a consistent seal even under varying conditions.

6. **Installation and Maintenance**: - Proper installation is key to the seal's performance, ensuring that it is correctly positioned and able to compress fully when the gate is closed. - Regular inspections and maintenance are necessary to monitor the seal for wear, tear, or damage, which could compromise its effectiveness. Over time, the seal may need to be replaced if it becomes too worn or loses its elasticity.

### Benefits:

- **Effective Sealing**: The 22mm diameter provides an appropriate balance between flexibility and sealing force, ensuring that the gate remains watertight when closed.- **Durability**: Made from robust materials, these seals are designed to withstand harsh environmental conditions and the constant pressure of the water.- **Flexibility**: The hollow bulb design allows the seal to adapt to the gate's surface and any minor irregularities, providing a consistent and reliable seal.

This specific size of a hollow bulb dam gate seal would be chosen based on the specific requirements of the dam gate, such as the expected water pressure, gate size, and the need for smooth gate operation.

| Business Type | Manufacturer, Exporter, Supplier |

| Tensile Strength | 14mpa |

| Steam Thickness | 16mm |

| Size (Inches) | 45x130x16mm |

| Application | Industrial |

| Country of Origin | India |

| Diameter | 45mm |

| Temperature Range | 70 Deg C |

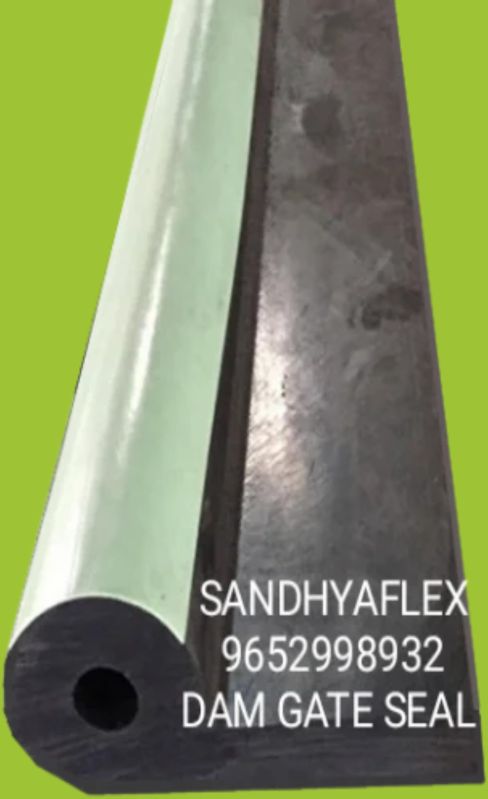

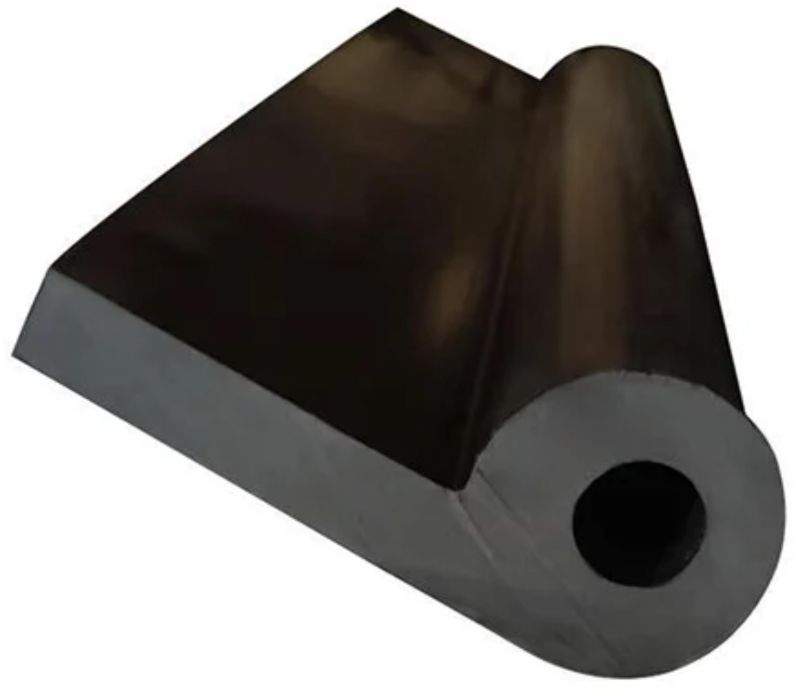

A **45mm Bull Dia Hollow Bulb Dam Gate Seal** refers to a hollow bulb seal designed for dam gates, with a "Bull Dia" (bulb diameter) of 45 millimeters. This larger diameter indicates a more robust sealing capability, suitable for handling higher pressures or larger gates.

### Key Features of a 45mm Bull Dia Hollow Bulb Dam Gate Seal:

1. **45mm Diameter**: - The "45mm Bull Dia" specifies that the diameter of the hollow bulb portion of the seal is 45 millimeters. This larger diameter allows the seal to compress more effectively, providing a strong and reliable seal against water leakage. - A 45mm diameter is relatively large, indicating that this seal is intended for use in gates where a significant sealing force is required due to higher water pressures or larger gate sizes.

2. **Hollow Bulb Design**: - The hollow bulb design is a key feature that allows the seal to compress and expand, accommodating movements and irregularities in the gate surface. When the gate is closed, the bulb compresses to form a watertight seal. - This design is particularly effective in providing a consistent seal, even if the gate or the surrounding structure has minor imperfections or if there are slight misalignments.

3. **Material**: - These seals are typically made from high-quality elastomeric materials, such as natural rubber, EPDM, or neoprene, which are known for their durability and resistance to environmental factors. - The material needs to withstand the rigors of continuous water exposure, UV radiation, and varying temperatures, ensuring the seal remains functional over a long period.

4. **Applications**: - A 45mm Bull Dia Hollow Bulb Seal is suitable for dam gates where the water pressure is substantial, or where the gate dimensions are large, requiring a more robust sealing solution. - Common applications include large spillway gates, radial gates, and other types of hydraulic structures where a strong seal is critical to prevent water from passing through when the gate is closed.

5. **Performance**: - The larger diameter of 45mm enhances the seal\\\'s ability to handle higher pressures without losing its sealing effectiveness. It can provide a more significant compression force, ensuring that even under extreme conditions, the gate remains sealed. - The seal\\\'s design ensures that it can adapt to any slight movements or shifts in the gate or its frame, maintaining a consistent seal.

6. **Installation and Maintenance**: - Proper installation is essential to ensure the seal functions correctly. The seal must be positioned accurately to compress fully when the gate is closed, creating the desired watertight barrier. - Regular inspections are necessary to check for any signs of wear, such as cracking, deformation, or loss of elasticity. Over time, the seal may need replacement if it becomes worn or damaged to maintain the integrity of the gate\\\'s sealing.

### Benefits:

- **Enhanced Sealing Capability**: The 45mm diameter provides a robust sealing force, making it ideal for applications where high water pressure is present.- **Durability**: Constructed from durable materials, these seals are designed to withstand harsh environmental conditions, including prolonged exposure to water, UV rays, and temperature fluctuations.- **Adaptability**: The hollow bulb design allows the seal to adjust to minor imperfections in the gate or surrounding structure, ensuring a consistent and effective seal.

### Summary:

A **45mm Bull Dia Hollow Bulb Dam Gate Seal** is a specialized sealing component designed for use in larger or higher-pressure dam gates. Its larger diameter and robust design make it well-suited to demanding hydraulic applications where a reliable and durable seal is essential to prevent water leakage and ensure the safe operation of the dam.

| Business Type | Manufacturer, Exporter, Supplier |

| Packaging Type | Packet |

| Steam Thickness | SANDHYAFLEX Bulb Seal/ Side Seal 1 Size25Diax 70x10mm Bulb Seal Size: Bulb Dia. 33mm |

| Size (Inches) | 25mm To 50mm Dia |

| Material | Rubber |

| Country of Origin | India |

| Diameter | SANDHYAFLEX Bulb Seal/ Side Seal 1 Size25Diax 70x10mm Bulb Seal Size: Bulb Dia. 33mm X 90mm |

| Hardness | 60 to 70 Shore A |

| Temperature | As per customers requirement |

| Packaging Size | SANDHYAFLEX Bulb Seal/ Side Seal 1 Size25Diax 70x10mm Bulb Seal Size: Bulb Dia. 33mm |

| Pressure Ranges | SANDHYAFLEX Bulb Seal/ Side Seal 1 Size25Diax 70x10mm Bulb Seal Size: Bulb Dia. 33mm |

| Elongation | 450% Min |

| Bore Size | 19,12,10mm |

| Velocity | SANDHYAFLEX Bulb Seal/ Side Seal 1 Size25Diax 70x10mm Bulb Seal Size: Bulb Dia. 33mm X 90mm |

| Temprature | As per customers requirement |

| Design | SANDHYAFLEX Bulb Seal/ Side Seal 1 Size25Diax 70x10mm Bulb Seal Size: Bulb Dia. 33mm X 90mm w |

The Sandhyaflex Hollow Bulb Dam Gate Seal is engineered to provide a watertight barrier for dam gates, effectively preventing water leakage and ensuring optimal performance of water control systems. citeturn0search0

\\nKey Features:

\\n- \\n

- \\n

Design: The hollow bulb configuration is specifically crafted to accommodate movements and deformations of dam gates, maintaining a consistent seal under varying pressures.

\\n \\n - \\n

Material Composition: Manufactured from high-quality rubber compounds, these seals offer exceptional durability and resilience. citeturn0search2

\\n \\n - \\n

Customization: Available in various sizes, with bulb diameters ranging from 25mm to 50mm, accommodating diverse project specifications. citeturn0search2

\\n \\n

Applications:

\\nThe Sandhyaflex Hollow Bulb Dam Gate Seals are widely utilized in various dam and hydroelectric projects to ensure effective water retention and control. citeturn0search0

\\nCompliance:

\\nThese seals are designed and manufactured in accordance with IS: 11855 standards, ensuring adherence to industry norms and quality benchmarks. citeturn0search1

\\nContact Information:

\\nFor detailed specifications, customization options, or to place an order, please reach out to Sandhya Enterprises:

\\n- \\n

- \\n

Phone: +91

\\n \\n - \\n

Email: info@

\\n \\n - \\n

Address: 5-24-1223/5/1, Ambedkar Nagar, Gajularamaram, Quthbullapur, Jeedimetla, Hyderabad - 500055, Telangana, India

\\n \\n

\\n

For comprehensive product details and diagrams, please refer to their official product documentation. citeturn0search1

| Business Type | Manufacturer, Exporter, Supplier |

| Size (Inches) | 4Inch, 33 |

| Color | Black |

| Usage | Oil Industry |

| Material | Rubber |

| Country of Origin | India |

| Type | Rubber Seals |

| Brand Name | Mexico |

| Finishing | Polished |

| Port | MUMBAI |

| Payment Terms | L/C |

| Delivery Time | 7 to 15 days |

| Packaging Details | Here are the **packaging details** for **PTFE Cladded Dam Rubber Seal**, a product typically used in **dams**, **hydropower plants**, and other water control structures to provide a **watertight seal** and prevent water leakage. --- ### **Packaging Details: PTFE Cladded Dam Rubber Seal** --- ### **Product Overview:** * **Product Name:** PTFE Cladded Dam Rubber Seal * **Material:** A composite material made from **rubber** and a **PTFE (Polytetrafluoroethylene) cladding** for enhanced durability and resistance to water, chemicals, and extreme temperatures. * **Applications:** Primarily used in **dam gates**, **sluices**, and **hydraulic structures** to provide a long-lasting seal for water and fluid control. PTFE offers excellent resistance to wear and corrosion. * **Sizes and Configurations:** Available in various sizes, depending on the specific design requirements of the dam or water control structure. Common sizes include **lengths** ranging from **1 meter to 10 meters** and **widths** up to **200 mm** or more. --- ### **Packaging Configuration:** #### **1. Coiling or Rolling:** * **PTFE Cladded Dam Rubber Seals** are typically **rolled or coiled** into **circular or cylindrical shapes** to prevent damage and maintain their integrity during transportation. * The seals may be wrapped in **protective film** or **plastic wrap** to keep them free from dirt and moisture. * If the seals are particularly long (e.g., **10 meters** or more), they are **coiled tightly** and secured with **cable ties** or **plastic bands** to maintain their shape. #### **2. Protective Wrapping:** * **Plastic Shrink-Wrapping**: The entire rolled or coiled rubber seal is typically **shrink-wrapped** or covered with a layer of **protective plastic** to shield it from dirt, moisture, and UV exposure. * **Foam or Rubber Inserts**: In some cases, protective foam or rubber inserts may be used around the **edges** or **ends** of the seal to protect the PTFE cladding from physical damage during handling or transportation. * **Corner Protection**: If the seal's packaging includes a **box** or **crate**, **foam corner protectors** may be applied to minimize risk of sharp impacts. #### **3. Bundling for Larger Orders:** * For larger orders, multiple rolls or coils of PTFE Cladded Rubber Seals may be **bundled together** using **strapping** or **reinforced plastic ties**. * Each bundle is then **shrink-wrapped** to secure the items and prevent them from shifting during shipment. #### **4. Crating (for International Shipments):** * For **international shipments** or when additional protection is required, the rolled or coiled rubber seals are placed into **wooden crates** or **strong cardboard boxes**. * The crates or boxes are sealed to protect the product from external environmental factors such as **humidity** or **physical handling damage**. * **Fumigation** may be applied to the crates to meet **international shipping standards** (e.g., ISPM-15) if required. --- ### **Container Loading (Approximate):** * **20-foot container:** * Typically holds around **6-10 pallets**, depending on the size of each rolled seal and the packaging method. * **Total weight**: \~ **1,500–3,000 kg** (can vary based on length and type of rubber seal). * **40-foot container:** * Can hold **12-20 pallets** of PTFE Cladded Dam Rubber Seals. * **Total weight**: \~ **3,000–6,000 kg**, depending on the product's weight and length. --- ### **Labeling Information:** Each bundle, crate, or box typically includes labels with the following information: * **Product Name**: PTFE Cladded Dam Rubber Seal * **Dimensions**: Length, width, and any relevant technical specifications (e.g., diameter of the coil). * **Quantity**: Number of pieces or rolls per pallet, crate, or container. * **Gross Weight**: Total weight of each bundle or crate. * **Batch Number** or **Lot Number**: For traceability. * **Manufacturer Details**: Name, address, and contact information of the manufacturer. * **Country of Origin**: Relevant information for export purposes. * **Handling Instructions**: Proper guidelines for handling, unloading, and storage to avoid damage to the seals. * **Storage Conditions**: Recommended storage conditions to avoid direct sunlight, excessive moisture, or heat exposure. --- ### **Storage Recommendations:** * **Temperature Control**: Store in a **cool, dry place** to prevent degradation of the rubber and PTFE. * **Avoid Direct Sunlight**: Prolonged exposure to UV rays can damage the PTFE cladding and cause the rubber to deteriorate. * **Flat Storage**: If stored in coils or rolls, ensure that they are placed on **flat surfaces** to prevent **uneven deformation** or damage. * **Avoid Heavy Weight on Seals**: Do not stack heavy objects on the seals during storage to prevent compression or deformation. --- ### **Handling Recommendations:** * **Use Forklifts** or **Pallet Jacks** to move pallets of PTFE Cladded Dam Rubber Seals, ensuring the product remains secure during transport. * **Protect Edges**: Avoid dropping or impacting the rolled seals to prevent damage to the rubber and PTFE cladding. * **Careful Uncoiling**: When removing the seals from their packaging, ensure they are **uncoiled slowly** and carefully to avoid **kinking** or **deformation**. --- ### **Shipping Considerations:** * **Weatherproofing:** Ensure that the packaging is **adequate for moisture protection**, especially if transporting over long distances or through areas with **high humidity**. * **Compliance with Export Regulations:** If shipping internationally, ensure the packaging complies with relevant **export regulations**, including **fumigation** or **ISPM-15** certification if necessary for wooden crates. --- Would you like to know more about the **specific palletization** or **shipment preparation** for PTFE Cladded Dam Rubber Seals or any **custom packaging options** based on your needs? |

Dam gate seals are designed to either retain water, prevent water penetration, or limit contaminated run off in civil engineering a Dam Gate Seals Application: Quality of Rubber Concept dam gate seals are very well accepted by various Gate Designers, Fabricators as well as Contractors, and been installed by Government and Private agencies, In concrete dams, tunnels / spillways, head regulator of intake structure, by-pass channels and draft tube of power house, the flow of water is controlled with the help of hydraulic gates. To prevent flow of water past a closed gate, seals are provided either on the gate or on the metal frame in the gate slot,

- Here at The Rubber Company we manufacture a wide variety of rubber gate seals to suit any application and environment. We produce our gate and dam seals from high quality rubber compounds in order to preserve the service life of the seal. The entire gate seal range features a high tensile strength as standard. Our gate seals also feature excellent abrasion and tear resistant properties. These properties are crucial as it enables the seal to withstand frequent use, while also maintaining sealing properties, If required we can coat many of our rubber gate seals with a high quality PTFE coating. A key advantage of PTFE coating is that it significantly reduces surface friction without the need for lubricant. On average the coefficient of friction can be reduced by over 70%, regardless of the base rubber compound,

- Flat bottom seals on high head gates should project no more than the deflection required to seal e.g. 3-5mm. If required we can coat many of our rubber gate seals with a high quality PTFE coating.

| Business Type | Manufacturer, Exporter, Supplier |

| Steam Thickness | 20mm |

| Application | Industrial |

| Size (Inches) | 50mm |

| Country of Origin | India |

| Number Of Flower | Dam Gate Seals |

| Diameter | 50mm |

| Temperature Range | -10 to 70deg c |

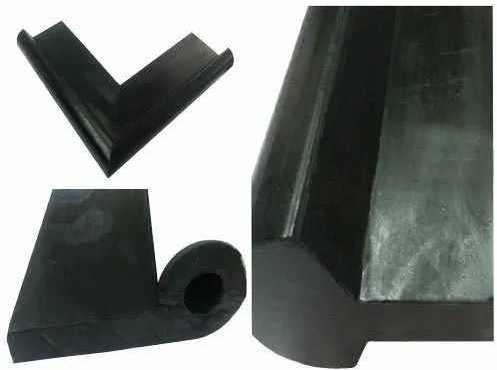

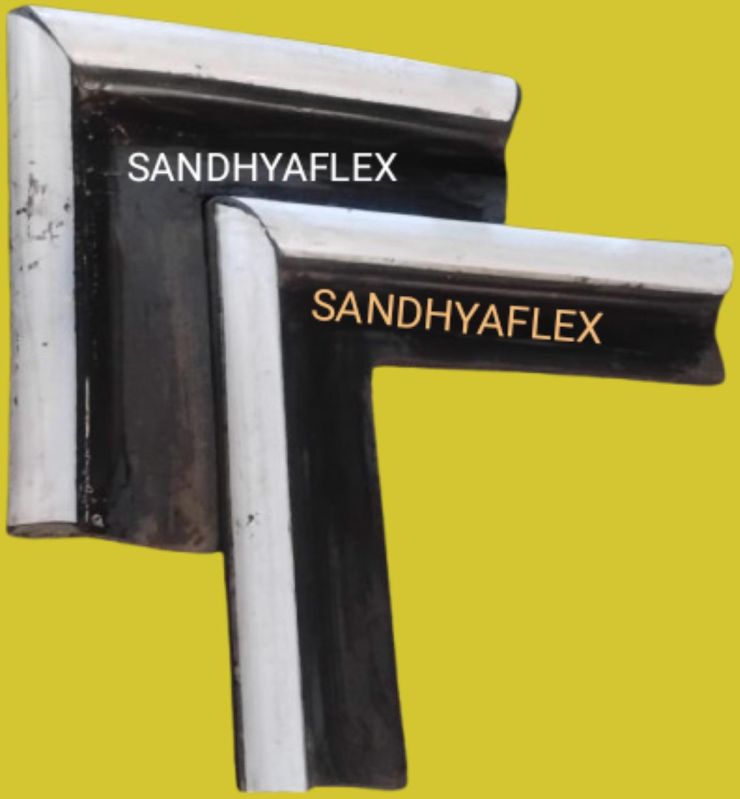

The Sandhyaflex Corner Dam Gasket Seal is a specialized sealing product, likely designed for use in dam construction or water-retaining structures such as basements, swimming pools, or water treatment plants. It is specifically engineered to form a reliable seal at corners, where two walls or surfaces meet, preventing water leakage or seepage at these critical junctions.

\\nSome key features of a Corner Dam Gasket Seal might include:

\\n- \\n

- \\n

Waterproofing: Its primary function is to create a tight, watertight seal at the corners of joints in concrete structures or barriers exposed to water or moisture.

\\n \\n - \\n

Durable Material: Likely made from high-quality materials like rubber or PVC (Polyvinyl Chloride), the gasket is designed to withstand the pressures exerted by water and resist degradation over time, especially in harsh environmental conditions.

\\n \\n - \\n

Flexibility: The design of the corner gasket may allow for flexibility, ensuring a secure and effective seal even if the concrete structure undergoes slight movements or shifting.

\\n \\n - \\n

Resistant to Chemical Exposure: Often, these seals are resistant to chemicals, making them suitable for use in diverse applications, including water treatment plants or industrial reservoirs.

\\n \\n

These gasket seals are essential for ensuring the integrity of water-retaining structures, particularly in areas with a high risk of water pressure or movement.

\\n\\n

If you\\\'re looking to know more about how these seals are installed or specific applications, feel free to ask!

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Application | Dam Gate Seals Application: Quality Of Rubber Concept Dam Gate Seals Are Very Well Accepted By Vario |

| Size (Inches) | 25mm To 50mm Dia Type Musical Note Dam Gate Seal A B C |

| Material | GATE RUBBER SEAL COMPOUNDS, BASED ON FOLLOWING ELASTOMERS, ARE USED FOR THE MANUFACTURING O |

| Steam Thickness | SANDHYAFLEX Bulb Seal/ Side Seal 1 Size25Diax 70x10mm Bulb Seal Size: Bulb Dia. 33mm |

| Packaging Type | Packet |

| Thickness | 10mm to 25mm |

| Diameter | SANDHYAFLEX Bulb Seal/ Side Seal 1 Size25Diax 70x10mm Bulb Seal Size: Bulb Dia. 33mm X 90mm |

| Temperature | -10 to 150 Deg C |

| Hardness | 63 Shore A |

| Port | A **port of dispatch** refers to the location (typically a seaport or airport) from which goods are |

| Payment Terms | D/A, Western Union |

| Delivery Time | 7to 15days |

| Packaging Details | packing as per dimension |

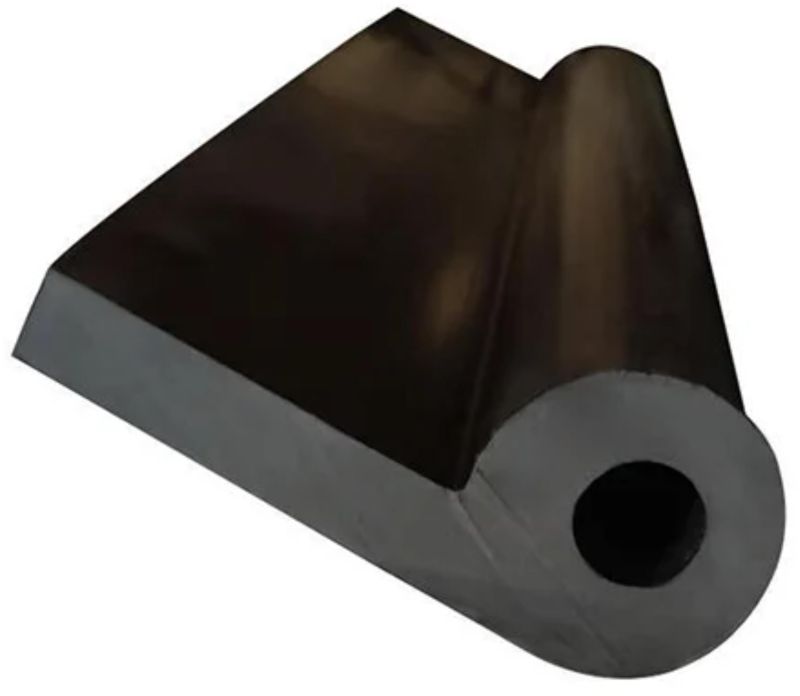

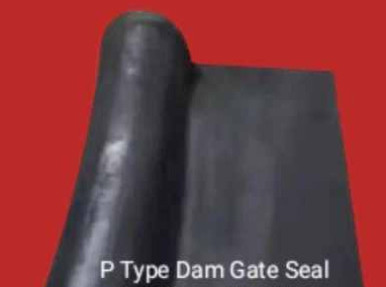

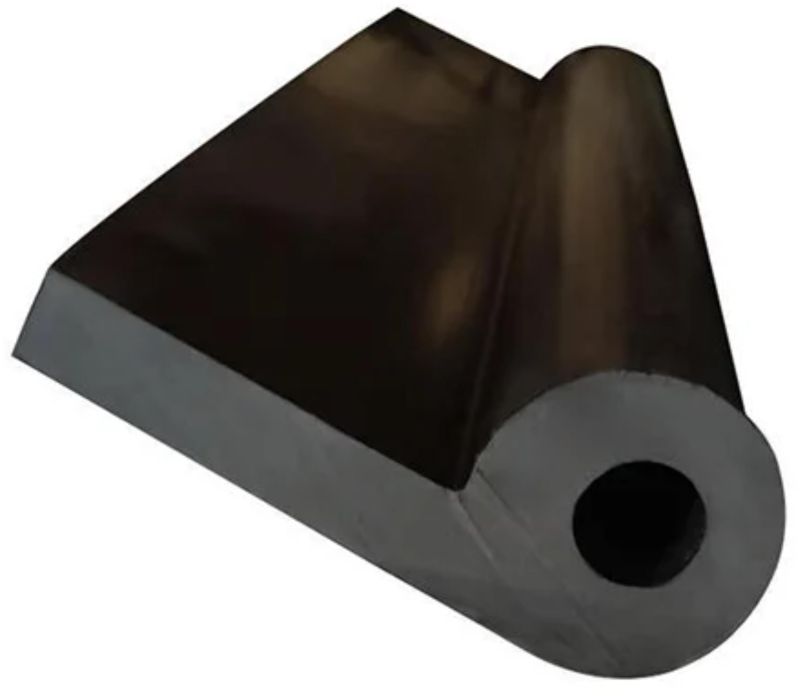

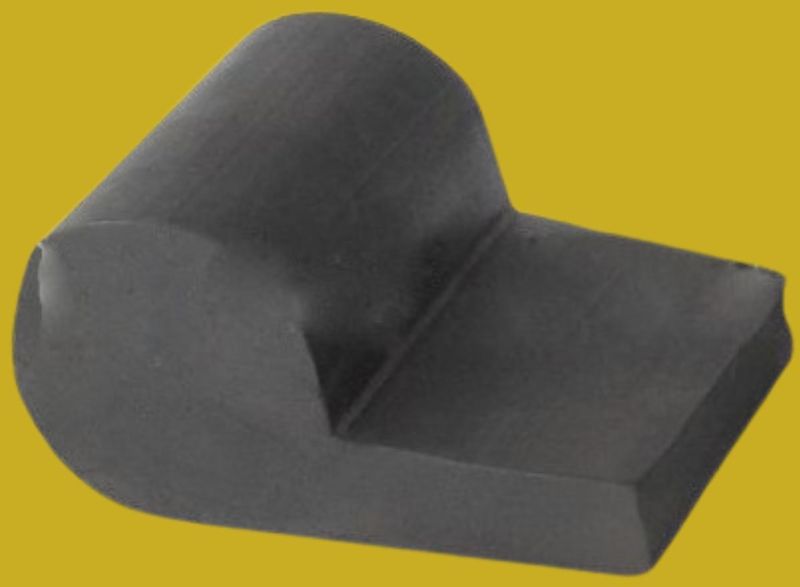

Common sizes and the arrangement of music note seal over the seal base plate. The initial interference note type seal shall vary from 2 to 5 mm depending upon the requirement and type of its installation discretion of the designer.

\\nThe music note seal is generally recommended to be used on gates operated for head up to 30 metres. hollow bulb music note seal is recommended for gates operated at low head up to 15 metres.

A solid bulb music note seal is recommended for gates operated at medium head, that is at a head

exceeding 15 m but less than 30 m

Sandhya Enterprises is renowned manufacturer and supplier of various types of Rubber Dam Gate Seals in Hyderabad Telangana, India. These rubber seals are being used in various Irrigation as well as Hydropower projects since many years. Dam gate seals are designed to either retain water, prevent water penetration, or limit contaminated run off in civil engineering a

\\nDam Gate Seals Application:

\\nQuality of Rubber Concept dam gate seals are very well accepted by various Gate Designers, Fabricators as well as Contractors, and been installed by Government and Private agencies. We have supplied numerous dam gate seals for number of dams across India and abroad, for various types of Gate designs such as following and many more.

\\nThe inherent elasticity and resilience of Rubber Concept dam gate seals allow it to retain its sealing effectiveness in situations where there are fluctuating movements caused by water pressure, traffic, subsidence or seismic movement.

\\n\\n

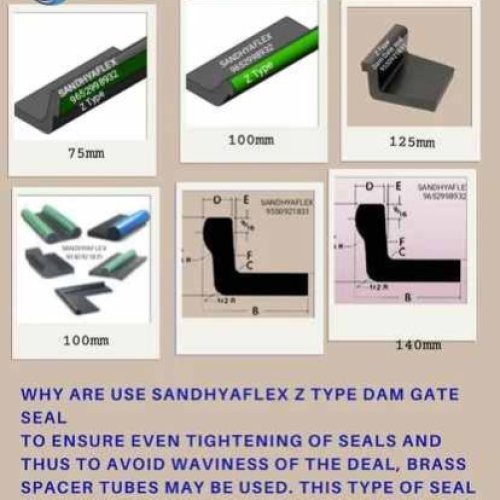

Dam Gate Seal Types:

\\nDepending on the head pressure, gate designers design gates and based on the design of gates, seals are selected.

\\n1. Musical Note seal: Also known as P-type seal or J- type or single stem seal. Generally used in low head gates, can be available with solid as well as hollow bulb. PTFE (Teflon) cladding available

\\n2. Double Stem seal: Generally used in high head gates, PTFE (Teflon) cladding available

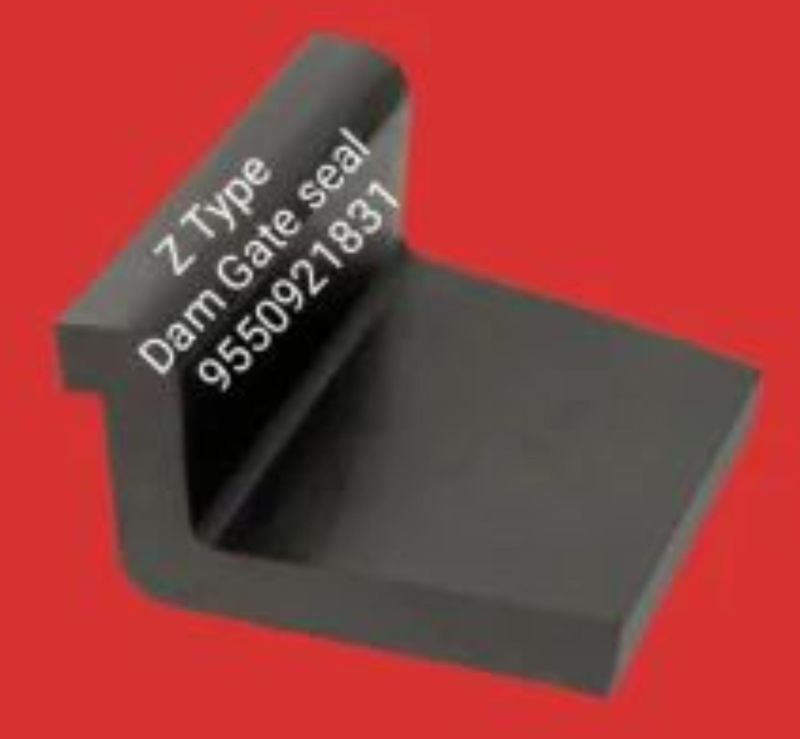

\\n3. Z-type rubber seal: Used in Radial gates, PTFE (Teflon) cladding available

\\n4. Flat Seal: Used as bottom seal, wedge or radius options available

\\n5. Special design seal: customized rubber seals

\\n6. Dam gate seal Corners: factory moulded or fabricated options available

\\nDam Gate Seal Materials used:

\\nCompounds, based on following elastomers, are used for the manufacturing of Rubber Dam Gate Seals:Natural Rubber (As per IS: 11855 / IS: 15466)

\\n§ EPDM Rubber

\\n§ PolyChloroprene Rubber / Neoprene R

\\n, Quality of which is better than extruded seals. Pressurized curing during moulding ensures close dimensional control, superior physical properties, compact microstructures, thus improved durability.

\\nWe can make the parts with good quality and h· Stage 1 : carbon black and other non-vulcanizing additives are combined with the raw rubber The term master batch is used for this first stage mixture.

\\n· Stage 2 : after stage 1 mixing has been completed, and time for cooling has been allowed, stage 2 mixing is carried out in which vulcanizing agents are addedighly appreciated service according to your drawing with dimensions or samples. This all gates seals are manufacturing conforming

| Business Type | Manufacturer, Exporter, Supplier |

| Packaging Type | Packet |

| Steam Thickness | 10 To 25 Mm |

| Size (Inches) | 25 To 50 Mm Bulb Dia |

| Application | Oil |

| Material | Rubber DAM GATE RUBBER SEAL COMPOUNDS,BASED ON FOLLOWING ELASTOMERS,ARE USED FOR THE MANUFACTURING |

| Country of Origin | India |

| Diameter | 25mm to 45mm |

| Thickness | 10 to 20mm |

| Hardness | 60 to 70 Shore A |

| Temperature | -10 to 100 Deg C |

| Packaging Size | as per Dimension and Qty |

Sandhya enterprises manufacturer and supplier of dam gate seal size:25mm dia to 50mm dia , width of steam 75mm to 125mm, thickness 10mm to 20mm, bottom dam gate seal. Size:10mmthickness to 75mm width to 125mm width. Dam gate seal bulb type p dype, z type , ptfe clladed, brass cladded. Dam gate rubber seal compounds, based on following elastomers, are used for the manufacturing of rubber dam gate seals :

· natural rubber

· epdm rubber

· poly chloroprene rubber

· neoprene rubber

mixing & compounding

in this process we are mixing the supporting ingredient in to the raw rubber to enhance its property. We are always follows the standards in making production. Mixing and rubber compounding with a formula to fabricate the desired product or article.

we follows two stage mixing process in order to get the best properties of rubber.

· stage 1 : carbon black and other non-vulcanizing additives are combined with the raw rubber the term master batch is used for this first stage mixture.

· stage 2 : after stage 1 mixing has been completed, and time for cooling has been allowed, stage 2 mixing is carried out in which vulcanizing agents are added

(dam gate rubber seal prepared by extrusion or molding methods)

extrusion process

· toi control porosity of seals. (porosity reduces the strength & life of rubber seal. )

· dimension accuracy (it helps to fit property & hence effects in performance at end)

· fast production with accuracy (it helps in timely delivery & making the process help free for workers)

· tensile strength property achievement (due to extrusion of rubber properly & hence increase the most important property of tensile strength.

· packing : all seals of inspection sent to dispatch department. When seals are cleaned again, silicon washing & coating to cover against weather. Packing and necessary labeling for desired destinations.

· shipping, delivery : dispatch : via best shipping companies, also on door delivery basis. (as per costumer requirement)

features:

· withstand atmospheric condition

· efficient and long lasting use

· low maintenance

| Business Type | Manufacturer, Exporter, Supplier |

| Tensile Strength | 14MPa |

| Steam Thickness | 19mm |

| Color | Black |

| Size (Inches) | 45mm Diax 160x19mm |

| Material | Nitrile Rubber (NBR) |

| Country of Origin | India |

| Diameter | 45mm |

| Temperature Range | 70 deg C |

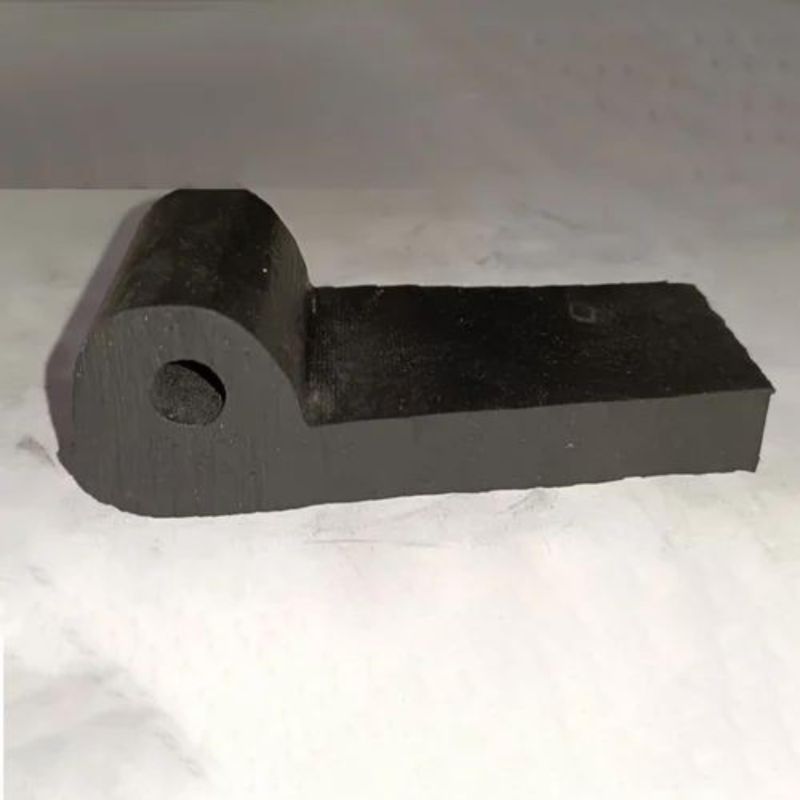

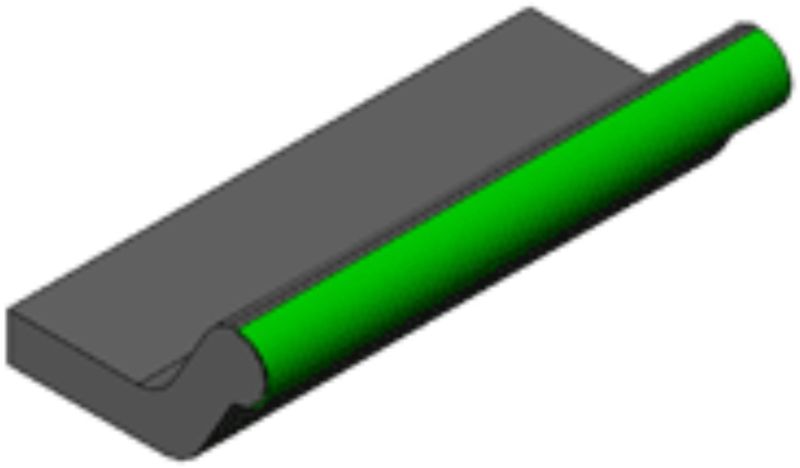

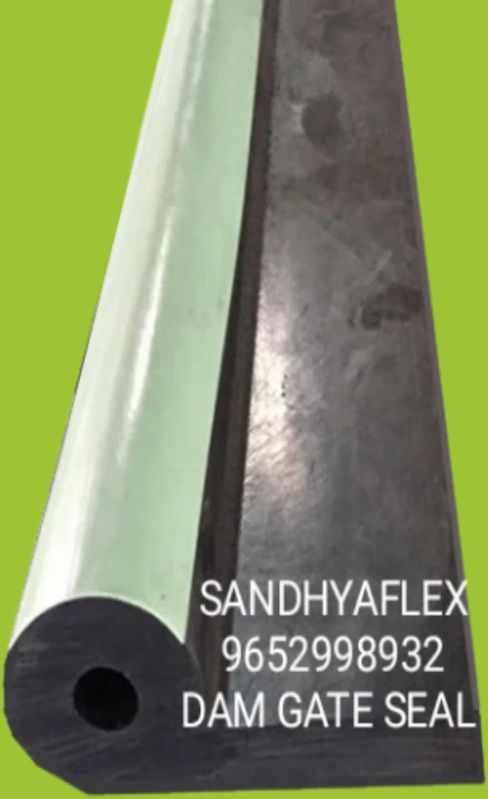

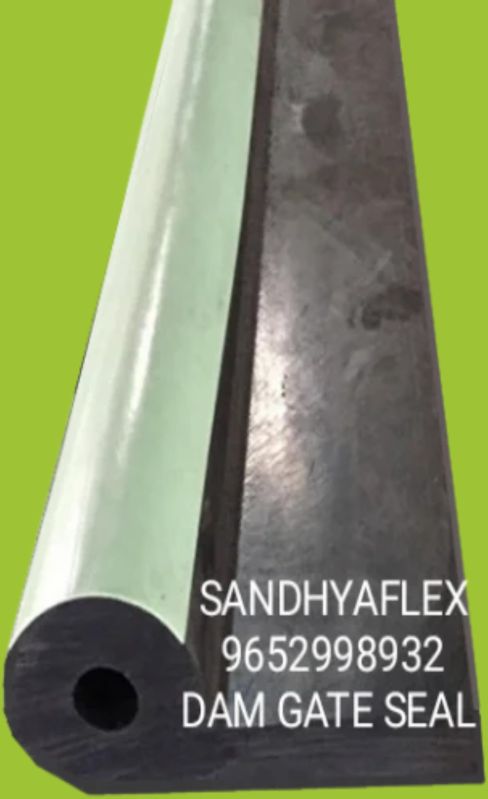

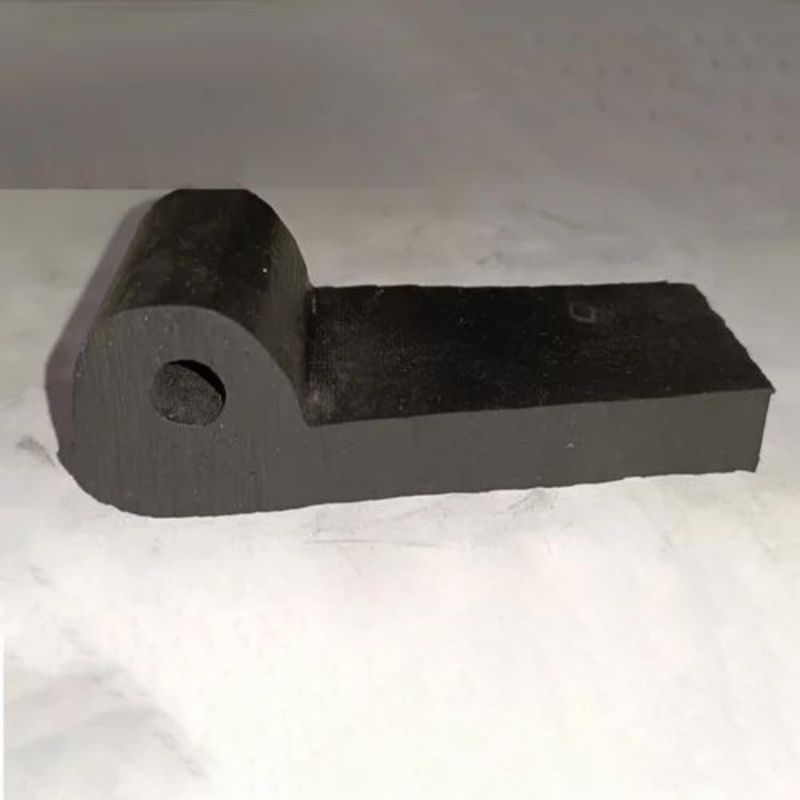

A **19mm Stem Thickness Hollow Bulb Dam Gate Seal** is a specific type of hollow bulb seal used in dam gates, characterized by a stem (the part that attaches to the gate structure) that is 19 millimeters thick. This seal is designed to provide a watertight barrier by compressing when the gate is closed, preventing water from leaking through the gate.

### Key Features of a 19mm Stem Thickness Hollow Bulb Dam Gate Seal:

1. **19mm Stem Thickness**: - The "stem thickness" refers to the thickness of the part of the seal that is anchored or attached to the gate or gate frame. A 19mm thickness indicates a relatively robust stem, providing strong attachment and stability for the seal. - The thickness of the stem is crucial as it determines the seal's durability, attachment security, and ability to handle the forces exerted by the gate and water pressure.

2. **Hollow Bulb Design**: - The seal features a hollow bulb, which is a flexible, cylindrical section that compresses under pressure to create a watertight seal. The hollow bulb is designed to deform when the gate is closed, ensuring that water does not pass through. - The hollow design allows the seal to adapt to irregularities in the gate's surface, providing consistent sealing performance even in challenging conditions.

3. **Material**: - These seals are typically made from durable, flexible elastomeric materials such as rubber, EPDM, or neoprene. These materials are selected for their ability to resist water, temperature fluctuations, and environmental wear. - The material ensures that the seal maintains its flexibility and sealing capability over time, even with repeated compression and exposure to harsh conditions.

4. **Applications**: - A 19mm Stem Thickness Hollow Bulb Dam Gate Seal is used in various types of dam gates, including spillway gates, sluice gates, and radial gates. The stem thickness makes it suitable for gates that require a strong attachment and where the seal must endure significant water pressure. - It is particularly useful in situations where a durable and secure seal is necessary to prevent water from leaking through the gate when closed.

5. **Performance**: - The 19mm thick stem provides a sturdy anchor for the hollow bulb, ensuring that the seal remains securely in place during gate operation. This is especially important in high-pressure applications where the seal is subjected to substantial forces. - The hollow bulb design ensures effective sealing by compressing to fill gaps and irregularities, maintaining a watertight barrier.

6. **Installation and Maintenance**: - The seal needs to be properly installed to ensure it functions correctly. The stem must be securely attached to the gate or frame, and the hollow bulb must be positioned to compress fully when the gate is closed. - Regular maintenance, including inspections for wear or damage, is necessary to ensure the seal continues to perform effectively. Over time, the seal may need to be replaced if it shows signs of degradation, such as cracking, loss of elasticity, or damage to the stem.

### Benefits:

- **Strong Attachment**: The 19mm stem thickness provides a robust and secure attachment to the gate, ensuring that the seal remains in place even under high pressure.- **Effective Sealing**: The hollow bulb design allows the seal to compress and adapt to the gate's surface, preventing water from leaking through.- **Durability**: Made from high-quality materials, the seal is designed to withstand environmental stress, including exposure to water, UV radiation, and temperature changes.

| Business Type | Manufacturer, Exporter, Supplier |

| Color | Black |

| Type | Dam Gate Seals |

| Country of Origin | India |

| Brand Name | Mexico |

| Material | Steel |

| Finishing | Polished |

| Material Grade | S316 |

| Shape | D Shape |

| Port | MUMBAI |

| Payment Terms | L/C |

| Delivery Time | 7 to 15 days |

| Packaging Details | Here are the **packaging details** for **Teflon Cladded Hollow Bulb Dam Gate Seals**, which are used in **dam gates**, **sluice gates**, and **hydraulic structures** to provide a **water-tight seal** and prevent water leakage in water control systems: --- ### **Packaging Details: Teflon Cladded Hollow Bulb Dam Gate Seal** --- ### **Product Overview:** * **Product Name:** Teflon Cladded Hollow Bulb Dam Gate Seal * **Material:** The seal consists of a **rubber core** (typically made from **EPDM or other elastomers**) with a **Teflon (PTFE) cladding** to enhance **resilience**, **corrosion resistance**, and **waterproofing**. * **Applications:** Used in **hydraulic engineering**, **dam gates**, **sluice gates**, and **water control structures** to provide a **long-lasting** and **high-performance** seal to prevent leakage and ensure water containment. * **Sizes and Configurations:** Typically available in **custom lengths** and **diameters** to match specific gate designs. Common configurations include **hollow bulb shapes** for compressing and forming an effective seal when under pressure. --- ### **Packaging Configuration:** #### **1. Coiling or Rolling:** * **Hollow Bulb Seals** are typically **rolled or coiled** to reduce space during shipping and prevent **damage** to the bulb shape. * The seals may be rolled into a **cylindrical shape** or **tight coils** and secured using **plastic bands** or **cable ties** to keep the seal intact and prevent it from unrolling. * **Protective layers** such as **plastic film** or **shrink wrap** are used to cover the rolled seal to shield it from **dirt**, **moisture**, or **external damage** during transport. #### **2. Protective Wrapping:** * **Shrink-wrapping** or **plastic film** is often used to **completely encase the coiled seal**, protecting it from moisture, dirt, and UV exposure during transportation and storage. * **Edge Protection**: Foam or rubber padding may be added at the ends of the coiled seal to protect the **Teflon cladding** and the **rubber core** from physical impact or abrasions. * **Foam or Cardboard Inserts** can be placed between the coils of the seal to prevent them from sticking together and to minimize damage. #### **3. Bundling for Larger Orders:** * For **bulk orders**, multiple rolls or coils of **Teflon Cladded Hollow Bulb Dam Gate Seals** may be **bundled together** with **reinforced plastic ties** or **straps** for ease of handling. * Each bundle is then **shrink-wrapped** to provide extra stability during handling and transport. #### **4. Crating (for International Shipments or Sensitive Orders):** * For **export shipments** or when extra protection is required, the coiled seals may be placed into **wooden crates** or **strong cardboard boxes**. * **Crates** are sealed securely to protect the seals from **moisture** or **physical handling damage**. * **Fumigation** may be required for wooden crates to comply with **international shipping standards** (e.g., ISPM-15) to prevent pest contamination. --- ### **Container Loading (Approximate):** * **20-foot container:** * Typically holds **6-8 pallets**, depending on the dimensions and packaging of each seal roll. * **Total weight**: \~ **1,500–2,500 kg**, depending on the length and material of the seal. * **40-foot container:** * Can hold **12-16 pallets** of coiled Teflon cladded hollow bulb seals. * **Total weight**: \~ **3,000–5,000 kg**, depending on the quantity and size of the seals. --- ### **Labeling Information:** Each pallet, crate, or bundle typically includes a label containing the following information: * **Product Name**: Teflon Cladded Hollow Bulb Dam Gate Seal * **Dimensions**: The seal’s length, diameter, and other relevant specifications (e.g., bulb diameter, core material). * **Quantity**: Number of rolls or coils per pallet or bundle. * **Gross Weight**: Total weight of each pallet or crate. * **Batch Number** or **Lot Number** for traceability. * **Manufacturer Details**: Name, address, and contact information of the manufacturer or distributor. * **Country of Origin**: Relevant for export documentation. * **Handling Instructions**: Recommended guidelines for safe handling, including how to **uncoil** the seals and prevent damage during installation. * **Storage Instructions**: Recommended storage conditions to avoid degradation due to **moisture** or **extreme temperatures**. --- ### **Storage Recommendations:** * **Temperature Control**: Store the seals in a **cool, dry place** to prevent the **rubber** and **Teflon** cladding from degrading over time. * **Avoid Direct Sunlight**: Prolonged exposure to UV rays can damage the **Teflon coating**, so it’s best to store the seals in a shaded or **covered** environment. * **Flat Storage**: Ideally, store coiled seals on **flat surfaces** to prevent **deformation** or **kinking**. * **Protection from Moisture**: Ensure that seals are stored in a **moisture-free environment**, as excessive humidity can cause the **rubber core** to degrade. --- ### **Handling Recommendations:** * **Forklift or Pallet Jack Handling**: Use appropriate **material handling equipment** to move pallets of Teflon Cladded Hollow Bulb Seals. Ensure the seals remain secure during transport. * **Uncoiling**: When uncoiling, **unroll the seals carefully** to avoid **bending** or **kinking**. * **Edge Protection**: Avoid impacts to the edges of the seals, as the **Teflon cladding** is more vulnerable to **abrasion** than the rubber core. --- ### **Shipping Considerations:** * **Weatherproofing**: Packaging should include moisture-resistant **plastic wrapping** or **shrink film** to prevent water damage during shipment. * **Crate or Box Usage**: For international shipments, ensure that the packaging meets any necessary standards, including **fumigation** and **pest control** measures for wooden crates. * **Compliance with Export Regulations**: Ensure that the product meets all relevant **export documentation** and **shipping regulations** for international deliveries. --- Would you like more specific details on **custom packaging options**, **shipment preparation**, or **transportation tips** for the **Teflon Cladded Hollow Bulb Dam Gate Seal**? Feel free to ask for further assistance! |

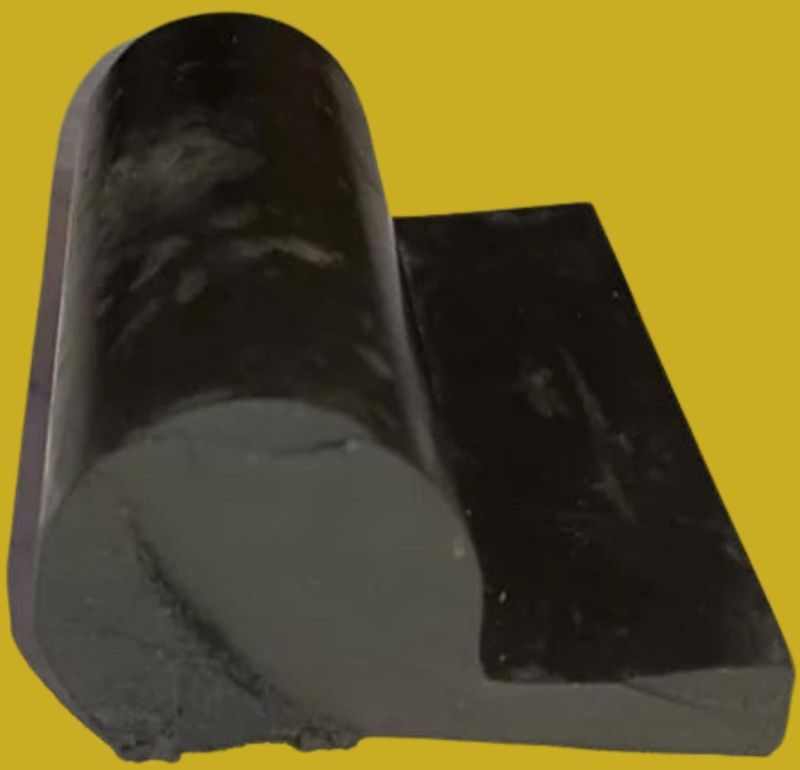

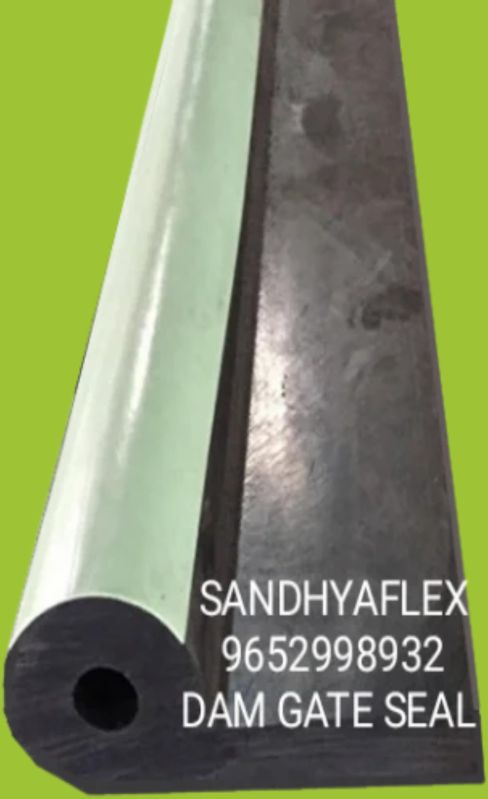

A **Teflon-Cladded Hollow Bulb Dam Gate Seal** combines the traditional hollow bulb seal design with a cladding of Teflon (PTFE - Polytetrafluoroethylene). This combination is designed to enhance the seal's performance, durability, and longevity, especially in demanding environments where the gate operates frequently or is exposed to harsh conditions.

### Key Features of a Teflon-Cladded Hollow Bulb Dam Gate Seal:

1. **Teflon (PTFE) Cladding**: - **Low Friction**: Teflon is well-known for its extremely low coefficient of friction, which means that the seal can operate smoothly with minimal resistance. This reduces wear and tear on the seal and the gate, ensuring longer operational life. - **Chemical Resistance**: Teflon is highly resistant to a wide range of chemicals, making the seal suitable for use in environments where exposure to corrosive substances might occur. - **Non-Stick Properties**: The non-stick nature of Teflon prevents debris, sediments, or other materials from adhering to the seal, which can otherwise interfere with the seal's performance. - **Durability**: Teflon cladding adds a layer of protection to the underlying rubber or elastomeric material, extending the seal's lifespan and enhancing its ability to withstand UV radiation, temperature extremes, and other environmental stressors.

2. **Hollow Bulb Design**: - The hollow bulb structure is the core of the seal, designed to compress under pressure to create a tight, watertight seal. The hollow section allows the seal to flex and adapt to the gate’s surface, accommodating any irregularities and ensuring effective sealing. - This design is especially useful in gates that experience movement or need to adjust to varying pressure levels, as the bulb can deform as needed while maintaining the integrity of the seal.

3. **Material Composition**: - The main body of the seal is typically made from durable elastomeric materials such as rubber or EPDM, which provide the necessary flexibility and resilience. - The Teflon cladding is applied to the surface of the seal, providing the benefits of PTFE without compromising the flexibility and compressibility of the underlying material.

4. **Applications**: - Teflon-cladded hollow bulb seals are ideal for use in dam gates where high durability and low maintenance are required. These seals are particularly beneficial in situations where the gates must open and close frequently, or where there is a high risk of exposure to chemicals or other corrosive elements. - They are commonly used in spillway gates, radial gates, and other hydraulic structures where water-tight integrity is critical.

5. **Performance**: - The combination of Teflon cladding with the hollow bulb design ensures that the seal can provide consistent, reliable sealing under various conditions. The low friction of Teflon reduces the force required to operate the gate, leading to smoother operation and less wear on mechanical components. - The chemical resistance of Teflon ensures that the seal remains effective even in harsh environments, while its durability helps prevent degradation over time.

6. **Installation and Maintenance**: - Proper installation is essential to ensure that the Teflon cladding does not get damaged and that the seal is correctly positioned to compress fully when the gate is closed. - While the Teflon cladding reduces the need for frequent maintenance, regular inspections are still important to check for any signs of wear or damage. Over time, if the seal or the Teflon cladding shows signs of wear, it may need to be replaced to maintain effective sealing.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Number Of Flower | Industrial Seals |

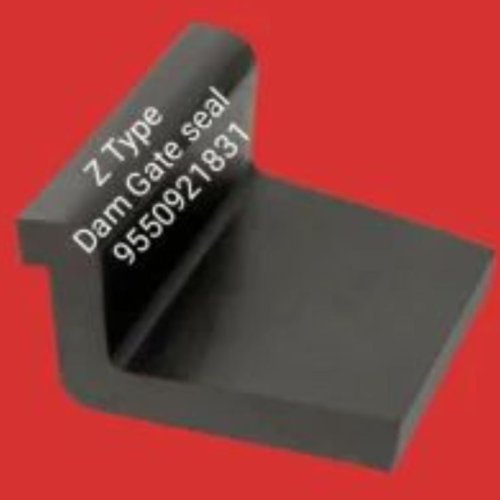

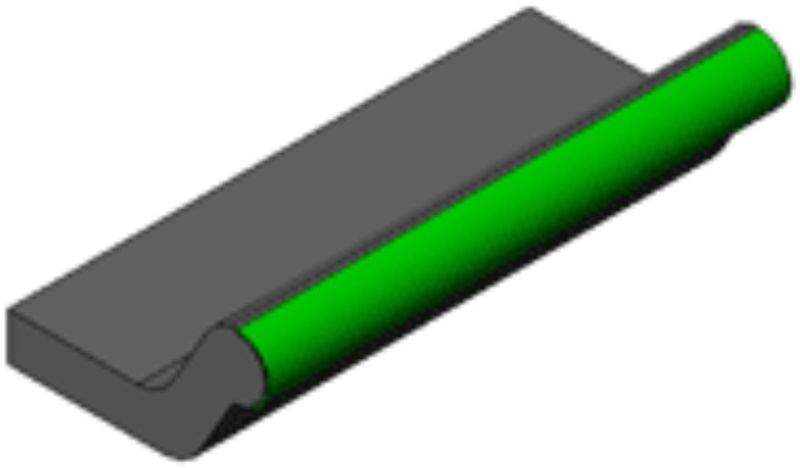

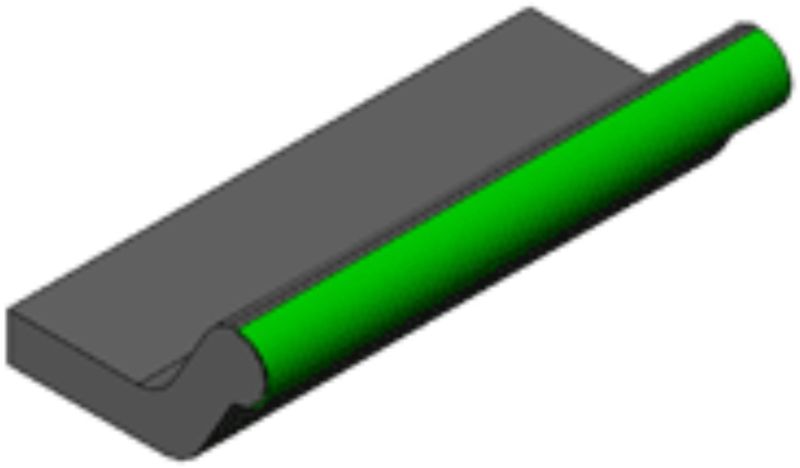

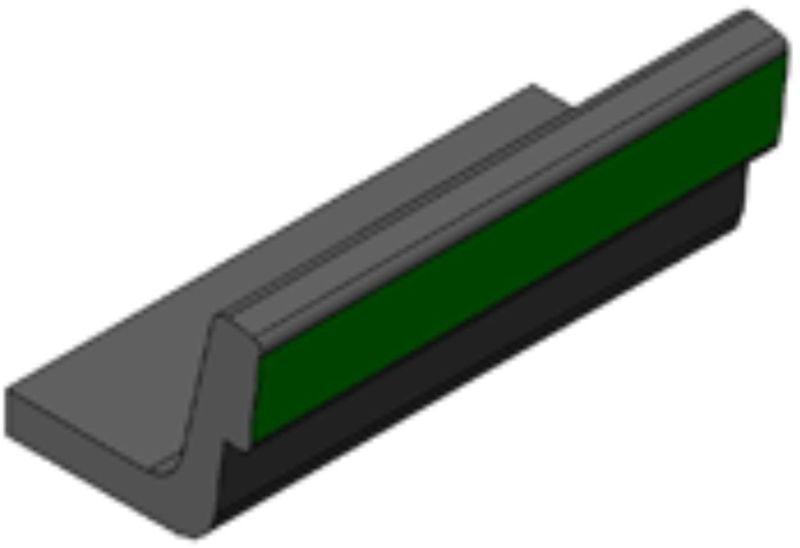

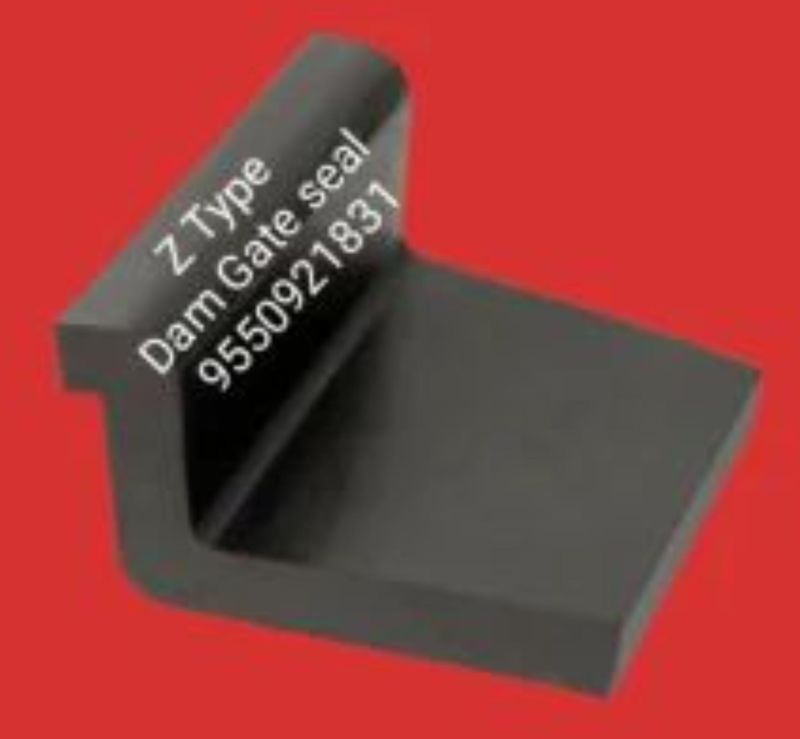

Z-type dam gate seals are specialized rubber or elastomeric seals used in hydraulic structures, particularly in dams and water control gates. These seals play a critical role in ensuring water-tightness and preventing leakage at the gates of dams, sluices, spillways, and other water retention or control structures.

### Key Uses and Features of Z-type Dam Gate Seals:

1. **Water Tightness**: Z-type seals are designed to create a strong, watertight seal between the gate and the frame or the gate and the sill. This is essential to prevent water leakage through the gates, ensuring the controlled flow of water.

2. **Durability**: These seals are typically made from durable rubber or elastomeric materials that can withstand harsh environmental conditions, including exposure to UV radiation, water, and varying temperatures.

3. **Flexibility and Compression**: The Z-shape of the seal allows it to flex and compress as the gate moves, ensuring a consistent seal even under varying pressures and movements. This flexibility is crucial for maintaining a seal over long periods, despite the opening and closing of the gates.

4. **Shock Absorption**: The Z-type design also helps in absorbing the impact and shock when the gate is operated, protecting both the gate structure and the sealing material from damage.

5. **Ease of Installation and Maintenance**: These seals are often designed for easy installation and replacement. Their shape allows them to be fitted into grooves or attached using fasteners, and their material properties allow for long service life with minimal maintenance.

6. **Applications**: - **Dam gates**: To control the flow of water and manage reservoir levels. - **Sluice gates**: For controlling water flow in irrigation channels, canals, and drainage systems. - **Spillways**: To prevent leakage in spillway gates, ensuring that water flows over the spillway as intended. - **Lock gates**: Used in canal lock systems to prevent water from seeping between the gates.

### Advantages:- **Long Lifespan**: Due to their robust construction and materials.- **Effective Sealing**: Provides reliable water-tightness even under high pressures.- **Resistance to Environmental Factors**: Resistant to weathering, ozone, and chemical exposure.

In summary, Z-type dam gate seals are essential components in hydraulic engineering, ensuring the effective and safe operation of water control structures by preventing leaks and maintaining water tightness.

| Business Type | Manufacturer, Exporter, Supplier |

| Tensile Strength | The Tensile Strength Of A **Z-type Dam Gate Seal** Is A Critical Property That Dete |

| Steam Thickness | The Dimensions Of A **Z-type Dam Gate Seal** Can Vary Depending On The Specific Requ |

| Color | Black |

| Application | Industrial |

| Size (Inches) | The Dimensions Of A **Z-type Dam Gate Seal** Can Vary Depending On The Specific Requirements Of The |

| Country of Origin | India |

| Type | Dam Gate Seals |

| Diameter | The dimensions of a **Z-type dam gate seal** can vary depending on the specific requirement |

| Temperature Range | The temperature resistance of a **Z-type dam gate seal** largely depends on the ma |

Z-type dam gate seals are specialized rubber or elastomeric seals used in hydraulic structures, particularly in dams and water control gates. These seals play a critical role in ensuring water-tightness and preventing leakage at the gates of dams, sluices, spillways, and other water retention or control structures.

### Key Uses and Features of Z-type Dam Gate Seals:

1. **Water Tightness**: Z-type seals are designed to create a strong, watertight seal between the gate and the frame or the gate and the sill. This is essential to prevent water leakage through the gates, ensuring the controlled flow of water.

2. **Durability**: These seals are typically made from durable rubber or elastomeric materials that can withstand harsh environmental conditions, including exposure to UV radiation, water, and varying temperatures.

3. **Flexibility and Compression**: The Z-shape of the seal allows it to flex and compress as the gate moves, ensuring a consistent seal even under varying pressures and movements. This flexibility is crucial for maintaining a seal over long periods, despite the opening and closing of the gates.

4. **Shock Absorption**: The Z-type design also helps in absorbing the impact and shock when the gate is operated, protecting both the gate structure and the sealing material from damage.

5. **Ease of Installation and Maintenance**: These seals are often designed for easy installation and replacement. Their shape allows them to be fitted into grooves or attached using fasteners, and their material properties allow for long service life with minimal maintenance.

6. **Applications**: - **Dam gates**: To control the flow of water and manage reservoir levels. - **Sluice gates**: For controlling water flow in irrigation channels, canals, and drainage systems. - **Spillways**: To prevent leakage in spillway gates, ensuring that water flows over the spillway as intended. - **Lock gates**: Used in canal lock systems to prevent water from seeping between the gates.

### Advantages:- **Long Lifespan**: Due to their robust construction and materials.- **Effective Sealing**: Provides reliable water-tightness even under high pressures.- **Resistance to Environmental Factors**: Resistant to weathering, ozone, and chemical exposure.

In summary, Z-type dam gate seals are essential components in hydraulic engineering, ensuring the effective and safe operation of water control structures by preventing leaks and maintaining water tightness.