-

sandhyaprises@gmail.com -

View Mobile Number

| Business Type | Manufacturer, Exporter, Supplier |

| Packaging Type | Packet |

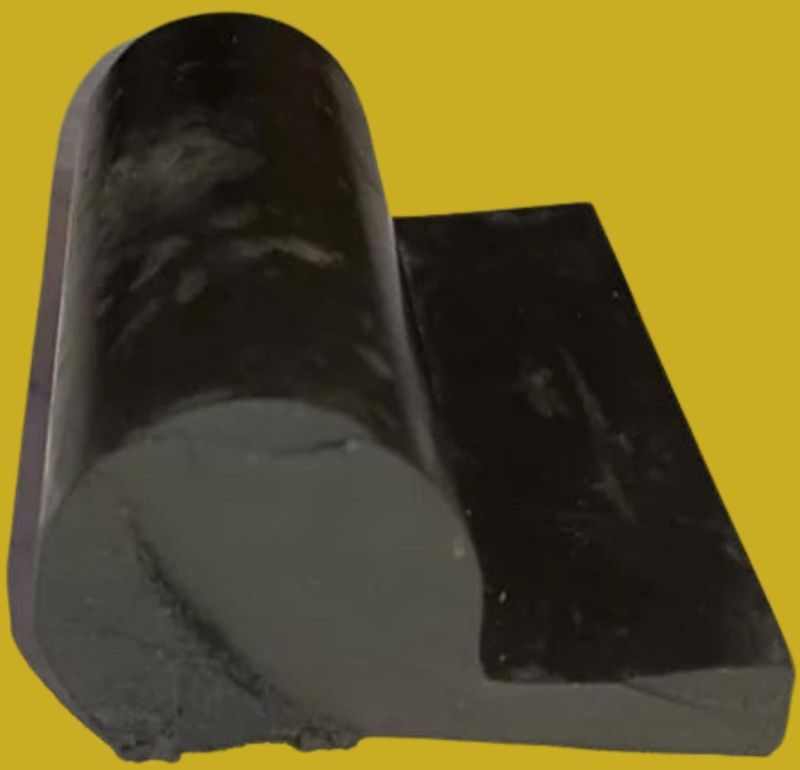

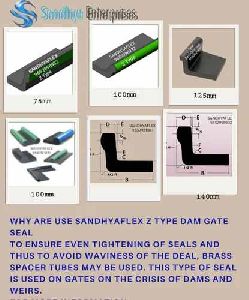

| Steam Thickness | 10 To 25 Mm |

| Size (Inches) | 25 To 50 Mm Bulb Dia |

| Click to view more | |

Product Details

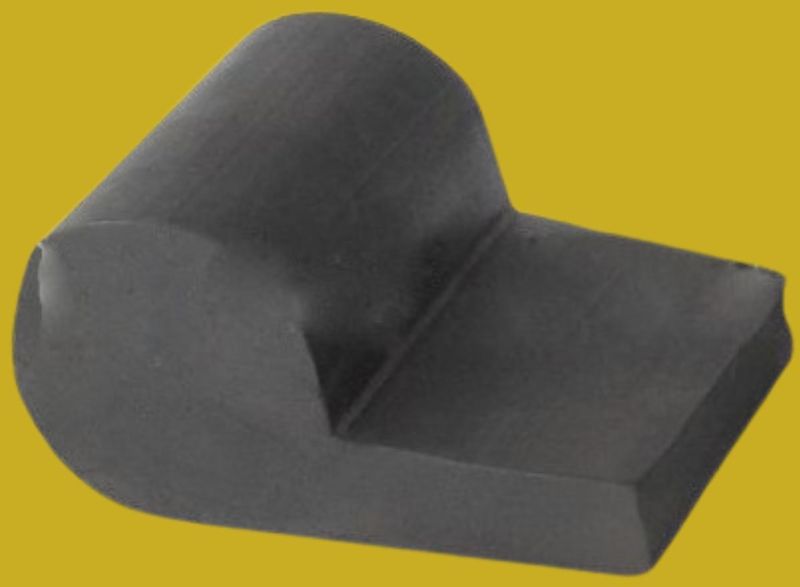

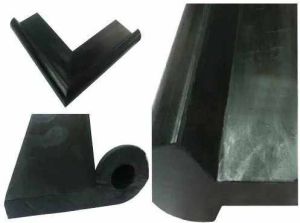

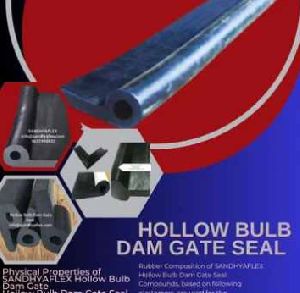

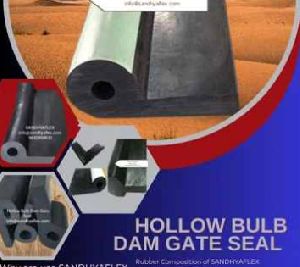

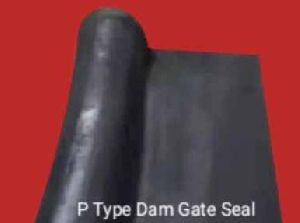

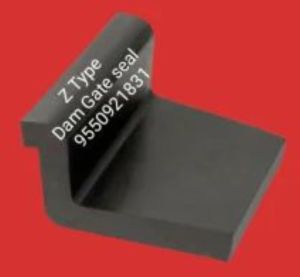

Sandhya enterprises manufacturer and supplier of dam gate seal size:25mm dia to 50mm dia , width of steam 75mm to 125mm, thickness 10mm to 20mm, bottom dam gate seal. Size:10mmthickness to 75mm width to 125mm width. Dam gate seal bulb type p dype, z type , ptfe clladed, brass cladded. Dam gate rubber seal compounds, based on following elastomers, are used for the manufacturing of rubber dam gate seals :

· natural rubber

· epdm rubber

· poly chloroprene rubber

· neoprene rubber

mixing & compounding

in this process we are mixing the supporting ingredient in to the raw rubber to enhance its property. We are always follows the standards in making production. Mixing and rubber compounding with a formula to fabricate the desired product or article.

we follows two stage mixing process in order to get the best properties of rubber.

· stage 1 : carbon black and other non-vulcanizing additives are combined with the raw rubber the term master batch is used for this first stage mixture.

· stage 2 : after stage 1 mixing has been completed, and time for cooling has been allowed, stage 2 mixing is carried out in which vulcanizing agents are added

(dam gate rubber seal prepared by extrusion or molding methods)

extrusion process

· toi control porosity of seals. (porosity reduces the strength & life of rubber seal. )

· dimension accuracy (it helps to fit property & hence effects in performance at end)

· fast production with accuracy (it helps in timely delivery & making the process help free for workers)

· tensile strength property achievement (due to extrusion of rubber properly & hence increase the most important property of tensile strength.

· packing : all seals of inspection sent to dispatch department. When seals are cleaned again, silicon washing & coating to cover against weather. Packing and necessary labeling for desired destinations.

· shipping, delivery : dispatch : via best shipping companies, also on door delivery basis. (as per costumer requirement)

features:

· withstand atmospheric condition

· efficient and long lasting use

· low maintenance