-

sandhyaprises@gmail.com -

View Mobile Number

| Business Type | Manufacturer, Supplier, Retailer |

| Brand Name | SANDHYAFLEX |

| Material | Neoprene Rubber, Rubber With MS Plate |

| Color | Black |

| Click to view more | |

Product Details

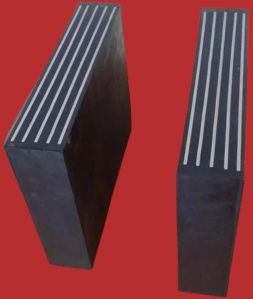

Sandhya enterprises plot no 5-24-122351, ambedkar nagar, gajuramaram, r.r. Dist.500055, hyderabad,telangana state. we are pleased to introduce ourselves as rubber sheet, textile braided hose, rubber suction hose, elastomeric bridge bearing, rubber moulded products, extruded products and pvc water stop, bridge expansion joint. We have leading and reputed consumer as our valued customers. It will be our pleasure if we can be of any service to your good selves and welcome your inquiries for your requirements. Our service is well established with the, cement industries, granites industries, electric power industries, ready mix industries, construction company and civil construction works. We go through the test certificate, physical properties, processing condition of the finished goods, grades etc and after looking at the final product we confidently recommended our valued customer to buy the product. Plot no 5-24-122351, ambedkar nagar, gajuramaram, r.r. Dist.500055,hyderabad telangana state. India email id: sandhyaprises@gmail.com, web:www.sandhyaprises.in contact no:+91-9652998932 ,9550921831 sandhya enterprises elastic moduluse test 10mpa to 20mpa ultimate compression strength 60mpa adhesion strength (stripping test) at 4mpa vl and 3mpa hl shear modulus test 5mpa vl and hl load 2h plot no 5-24-122351, ambedkar nagar, gajuramaram, r.r. Dist.500055,hyderabad telangana state. technical details sr no. Test unit specification and testing method specimens 1 hardness irhd is: 3400 (part ii) cl.5.1.2.2 4.0mm (min ) thickness of test specimen 2 tensile strength mpa is:3400 ( part i) table 1 type -1 thick- 2.0 +.0.20mm width 6.0 + 0.40mm bench mark-25.0mm (max) 3 elongation at break % 4 adhesion strength (metal to rubber knm is:3400 ( part xiv) cl.3.3 length -125mm width-25mm 5 ash content % is:3400 (part xxii) cl. A-8.3.1 is 1 g (min) 6 polymer idenAn elastomeric bridge bearing is a specialized component used in bridge construction and infrastructure projects. It is designed to provide support, flexibility, and load transfer between the bridge superstructure and substructure while accommodating movements caused by thermal expansion, contraction, and other factors. The packing details of elastomeric bridge bearings may vary depending on the manufacturer and supplier. However, here are some general considerations: 1. Quantity: The packaging should indicate the number of elastomeric bridge bearings included in a single pack. It can range from one bearing to multiple bearings, depending on the packaging configuration and supplier's specifications. 2. Size and Dimensions: The packaging may specify the size and dimensions of the elastomeric bridge bearing. This information helps determine if the bearing is suitable for the intended application and the bridge design requirements. 3. Material: The packaging may mention the specific elastomeric material used for the bearing construction. Elastomeric bridge bearings are typically made from high-quality synthetic rubber compounds that offer excellent durability, resilience, and load-bearing capacity. 4. Design and Load Capacity: The packaging may provide information about the design type and load capacity of the elastomeric bridge bearing. This includes details such as the maximum vertical load, horizontal load, rotational capacity, and allowable displacements. 5. Surface Treatment: The packaging may indicate if the elastomeric bridge bearings have any specific surface treatment, such as an anti-slip or corrosion-resistant coating. These treatments can enhance the performance and longevity of the bearings. 6. Packaging Material: The packaging itself may be mentioned, indicating the type of material used, such as cardboard boxes or crates. The packaging should provide sufficient protection to prevent damage during transportation and storage. 7. Installation Instructions: The packaging may include installation instructions or guidelines, describing the proper installation methods and