-

sandhyaprises@gmail.com -

View Mobile Number

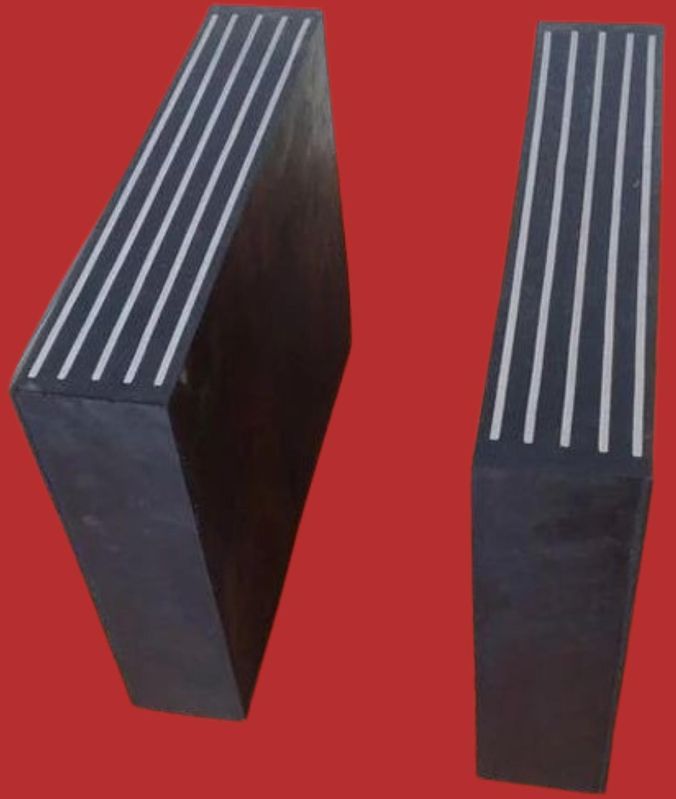

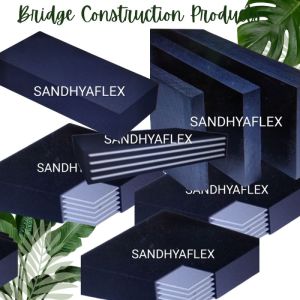

| Business Type | Manufacturer, Exporter, Supplier |

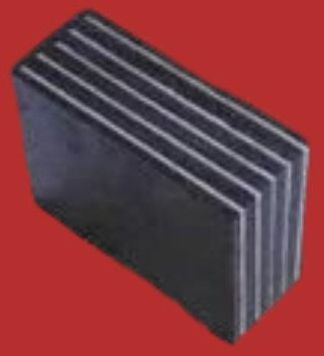

| Color | Black |

| Thickness | 25-144 Mm |

| Tensile Strength | 17.0MPa |

| Click to view more | |

Product Details

The Sandhyaflex Laminated Elastomeric Bridge Bearing is a specialized bearing component used in bridge construction to provide support, distribute loads, and accommodate movements such as thermal expansion, contraction, and settlement. It is designed to absorb forces from traffic loads, weather changes, and vibrations, ensuring the stability and longevity of bridges and other structures.

Key Features:-

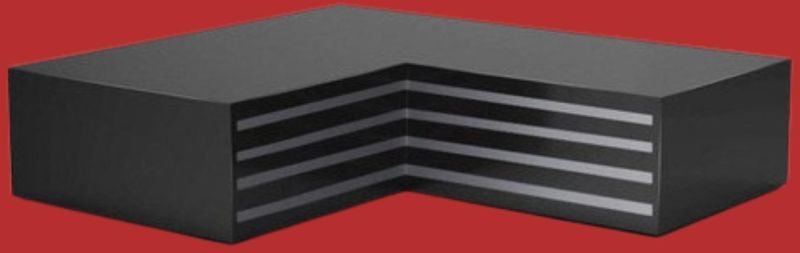

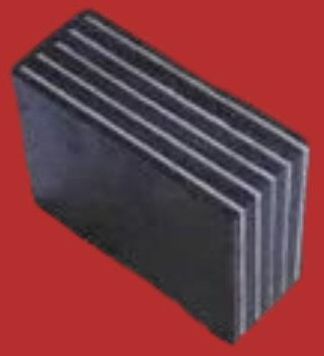

Laminated Construction:

- The bearing consists of multiple layers or laminates of elastomeric (rubber-based) materials, which are bonded together with steel plates. This laminated design helps to distribute loads evenly and provides flexibility to handle vertical and horizontal movements.

- Elastomeric materials are chosen for their high compressive strength, durability, and flexibility, making them ideal for dynamic loads and structural movement.

-

Load Distribution and Flexibility:

- These bearings help in transferring loads from the superstructure (like a bridge deck) to the substructure (like the foundation or piers) while allowing for movement.

- They accommodate vertical and horizontal displacements, as well as angular rotations caused by traffic, thermal expansion, or settlement.

-

Resistance to Environmental Factors:

- Elastomeric materials are resistant to weathering, UV rays, chemicals, and ozone, ensuring the bearing's longevity in outdoor environments, even under harsh conditions.

- They are also resistant to water, oil, and fuel exposure, which helps in protecting the bridge structure in challenging climates.

-

Durability:

- Laminated elastomeric bearings are designed to last for long periods, reducing maintenance requirements and contributing to the overall longevity of the bridge.

- Their ability to absorb shocks and vibrations helps prevent damage to the bridge structure from repeated traffic loads or seismic activities.

-

Applications:

- Bridge construction: To support the weight of the bridge and allow for safe and efficient movement.

- Viaducts and flyovers: For similar load-bearing and movement accommodation in overpasses.

- Marine and road infrastructure: In areas that experience heavy traffic and harsh weather conditions.

-

Cost-Effectiveness:

- Compared to other bearing types, laminated elastomeric bearings are relatively cost-effective and provide a good balance between performance, maintenance, and longevity.

- High load-bearing capacity: Suitable for heavy traffic and long-span bridges.

- Accommodates movement: Ideal for structures subjected to thermal expansion, contraction, and settlement.

- Durability and weather resistance: Designed to last in tough environmental conditions.

- Reduces maintenance: The long lifespan reduces the need for frequent repairs or replacements.

These bearings are a crucial component in ensuring the safety, stability, and longevity of bridges and related infrastructure. Would you like more information on the installation process or a comparison to other types of bearings used in bridge construction?