-

sandhyaprises@gmail.com -

View Mobile Number

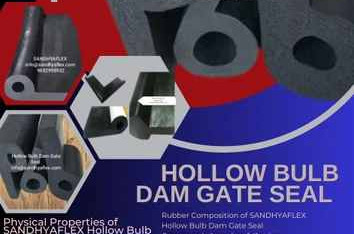

| Business Type | Manufacturer, Exporter, Supplier |

| Color | Black |

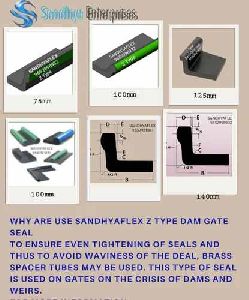

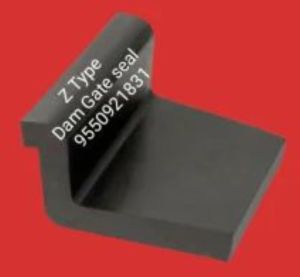

| Type | Dam Gate Seals |

| Country of Origin | India |

| Click to view more | |

Product Details

---

### **Packaging Details: Teflon Cladded Hollow Bulb Dam Gate Seal**

---

### **Product Overview:**

* **Product Name:** Teflon Cladded Hollow Bulb Dam Gate Seal

* **Material:** The seal consists of a **rubber core** (typically made from **EPDM or other elastomers**) with a **Teflon (PTFE) cladding** to enhance **resilience**, **corrosion resistance**, and **waterproofing**.

* **Applications:** Used in **hydraulic engineering**, **dam gates**, **sluice gates**, and **water control structures** to provide a **long-lasting** and **high-performance** seal to prevent leakage and ensure water containment.

* **Sizes and Configurations:** Typically available in **custom lengths** and **diameters** to match specific gate designs. Common configurations include **hollow bulb shapes** for compressing and forming an effective seal when under pressure.

---

### **Packaging Configuration:**

#### **1. Coiling or Rolling:**

* **Hollow Bulb Seals** are typically **rolled or coiled** to reduce space during shipping and prevent **damage** to the bulb shape.

* The seals may be rolled into a **cylindrical shape** or **tight coils** and secured using **plastic bands** or **cable ties** to keep the seal intact and prevent it from unrolling.

* **Protective layers** such as **plastic film** or **shrink wrap** are used to cover the rolled seal to shield it from **dirt**, **moisture**, or **external damage** during transport.

#### **2. Protective Wrapping:**

* **Shrink-wrapping** or **plastic film** is often used to **completely encase the coiled seal**, protecting it from moisture, dirt, and UV exposure during transportation and storage.

* **Edge Protection**: Foam or rubber padding may be added at the ends of the coiled seal to protect the **Teflon cladding** and the **rubber core** from physical impact or abrasions.

* **Foam or Cardboard Inserts** can be placed between the coils of the seal to prevent them from sticking together and to minimize damage.

#### **3. Bundling for Larger Orders:**

* For **bulk orders**, multiple rolls or coils of **Teflon Cladded Hollow Bulb Dam Gate Seals** may be **bundled together** with **reinforced plastic ties** or **straps** for ease of handling.

* Each bundle is then **shrink-wrapped** to provide extra stability during handling and transport.

#### **4. Crating (for International Shipments or Sensitive Orders):**

* For **export shipments** or when extra protection is required, the coiled seals may be placed into **wooden crates** or **strong cardboard boxes**.

* **Crates** are sealed securely to protect the seals from **moisture** or **physical handling damage**.

* **Fumigation** may be required for wooden crates to comply with **international shipping standards** (e.g., ISPM-15) to prevent pest contamination.

---

### **Container Loading (Approximate):**

* **20-foot container:**

* Typically holds **6-8 pallets**, depending on the dimensions and packaging of each seal roll.

* **Total weight**: \\~ **1,500–2,500 kg**, depending on the length and material of the seal.

* **40-foot container:**

* Can hold **12-16 pallets** of coiled Teflon cladded hollow bulb seals.

* **Total weight**: \\~ **3,000–5,000 kg**, depending on the quantity and size of the seals.

---

### **Labeling Information:**

Each pallet, crate, or bundle typically includes a label containing the following information:

* **Product Name**: Teflon Cladded Hollow Bulb Dam Gate Seal

* **Dimensions**: The seal’s length, diameter, and other relevant specifications (e.g., bulb diameter, core material).

* **Quantity**: Number of rolls or coils per pallet or bundle.

* **Gross Weight**: Total weight of each pallet or crate.

* **Batch Number** or **Lot Number** for traceability.

* **Manufacturer Details**: Name, address, and contact information of the manufacturer or distributor.

* **Country of Origin**: Relevant for export documentation.

* **Handling Instructions**: Recommended guidelines for safe handling, including how to **uncoil** the seals and prevent damage during installation.

* **Storage Instructions**: Recommended storage conditions to avoid degradation due to **moisture** or **extreme temperatures**.

---

### **Storage Recommendations:**

* **Temperature Control**: Store the seals in a **cool, dry place** to prevent the **rubber** and **Teflon** cladding from degrading over time.

* **Avoid Direct Sunlight**: Prolonged exposure to UV rays can damage the **Teflon coating**, so it’s best to store the seals in a shaded or **covered** environment.

* **Flat Storage**: Ideally, store coiled seals on **flat surfaces** to prevent **deformation** or **kinking**.

* **Protection from Moisture**: Ensure that seals are stored in a **moisture-free environment**, as excessive humidity can cause the **rubber core** to degrade.

---

### **Handling Recommendations:**

* **Forklift or Pallet Jack Handling**: Use appropriate **material handling equipment** to move pallets of Teflon Cladded Hollow Bulb Seals. Ensure the seals remain secure during transport.

* **Uncoiling**: When uncoiling, **unroll the seals carefully** to avoid **bending** or **kinking**.

* **Edge Protection**: Avoid impacts to the edges of the seals, as the **Teflon cladding** is more vulnerable to **abrasion** than the rubber core.

---

### **Shipping Considerations:**

* **Weatherproofing**: Packaging should include moisture-resistant **plastic wrapping** or **shrink film** to prevent water damage during shipment.

* **Crate or Box Usage**: For international shipments, ensure that the packaging meets any necessary standards, including **fumigation** and **pest control** measures for wooden crates.

* **Compliance with Export Regulations**: Ensure that the product meets all relevant **export documentation** and **shipping regulations** for international deliveries.

---

Would you like more specific details on **custom packaging options**, **shipment preparation**, or **transportation tips** for the **Teflon Cladded Hollow Bulb Dam Gate Seal**? Feel free to ask for further assistance!

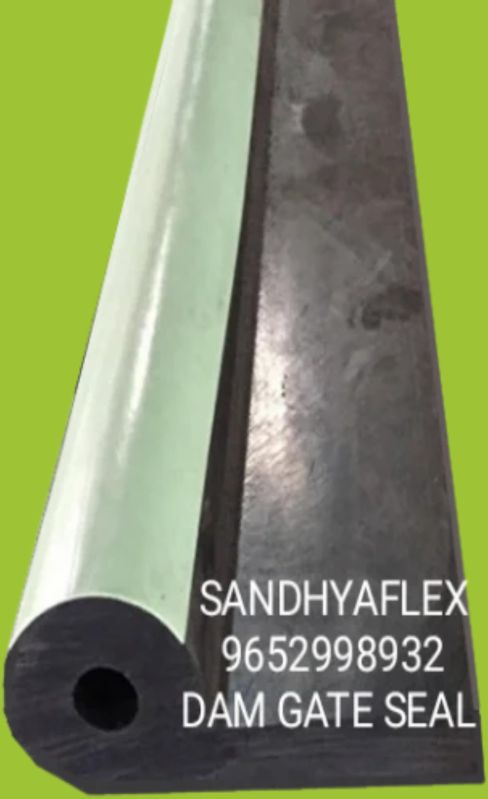

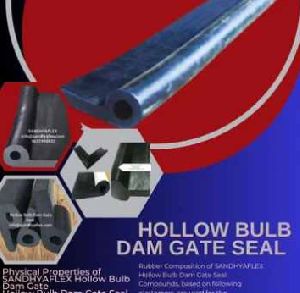

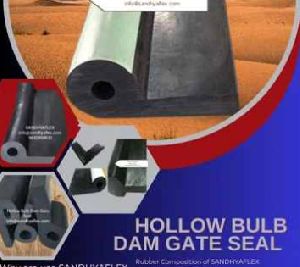

A **Teflon-Cladded Hollow Bulb Dam Gate Seal** combines the traditional hollow bulb seal design with a cladding of Teflon (PTFE - Polytetrafluoroethylene). This combination is designed to enhance the seal's performance, durability, and longevity, especially in demanding environments where the gate operates frequently or is exposed to harsh conditions.

### Key Features of a Teflon-Cladded Hollow Bulb Dam Gate Seal:

1. **Teflon (PTFE) Cladding**: - **Low Friction**: Teflon is well-known for its extremely low coefficient of friction, which means that the seal can operate smoothly with minimal resistance. This reduces wear and tear on the seal and the gate, ensuring longer operational life. - **Chemical Resistance**: Teflon is highly resistant to a wide range of chemicals, making the seal suitable for use in environments where exposure to corrosive substances might occur. - **Non-Stick Properties**: The non-stick nature of Teflon prevents debris, sediments, or other materials from adhering to the seal, which can otherwise interfere with the seal's performance. - **Durability**: Teflon cladding adds a layer of protection to the underlying rubber or elastomeric material, extending the seal's lifespan and enhancing its ability to withstand UV radiation, temperature extremes, and other environmental stressors.

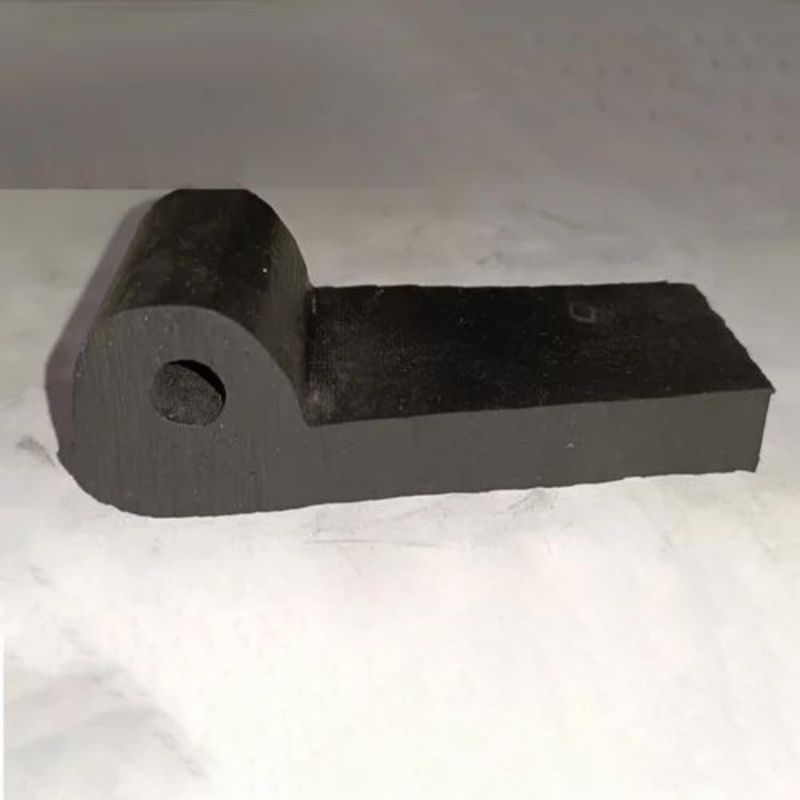

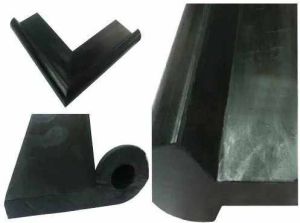

2. **Hollow Bulb Design**: - The hollow bulb structure is the core of the seal, designed to compress under pressure to create a tight, watertight seal. The hollow section allows the seal to flex and adapt to the gate’s surface, accommodating any irregularities and ensuring effective sealing. - This design is especially useful in gates that experience movement or need to adjust to varying pressure levels, as the bulb can deform as needed while maintaining the integrity of the seal.

3. **Material Composition**: - The main body of the seal is typically made from durable elastomeric materials such as rubber or EPDM, which provide the necessary flexibility and resilience. - The Teflon cladding is applied to the surface of the seal, providing the benefits of PTFE without compromising the flexibility and compressibility of the underlying material.

4. **Applications**: - Teflon-cladded hollow bulb seals are ideal for use in dam gates where high durability and low maintenance are required. These seals are particularly beneficial in situations where the gates must open and close frequently, or where there is a high risk of exposure to chemicals or other corrosive elements. - They are commonly used in spillway gates, radial gates, and other hydraulic structures where water-tight integrity is critical.

5. **Performance**: - The combination of Teflon cladding with the hollow bulb design ensures that the seal can provide consistent, reliable sealing under various conditions. The low friction of Teflon reduces the force required to operate the gate, leading to smoother operation and less wear on mechanical components. - The chemical resistance of Teflon ensures that the seal remains effective even in harsh environments, while its durability helps prevent degradation over time.

6. **Installation and Maintenance**: - Proper installation is essential to ensure that the Teflon cladding does not get damaged and that the seal is correctly positioned to compress fully when the gate is closed. - While the Teflon cladding reduces the need for frequent maintenance, regular inspections are still important to check for any signs of wear or damage. Over time, if the seal or the Teflon cladding shows signs of wear, it may need to be replaced to maintain effective sealing.