-

sandhyaprises@gmail.com -

View Mobile Number

100 Piece (MOQ)

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | sandhyaflex |

| Material | Bitumen Pad |

| Driven Type | Battery |

| Click to view more | |

Product Details

---

### ✅ **Packaging Details: Supreme HD100 DuraBoard**

---

### 📌 **Product Overview:**

* **Product Name:** Supreme HD100 DuraBoard

* **Material:** High-density fiberboard impregnated with bitumen or resin for superior **moisture resistance**, **strength**, and **durability**.

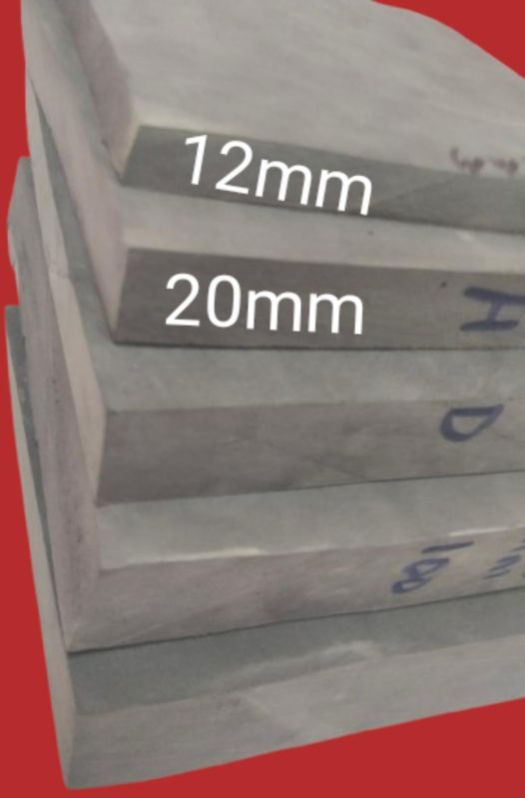

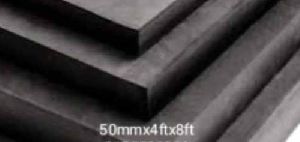

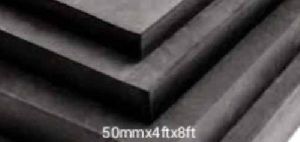

* **Thickness:** Typically available in **12 mm, 18 mm, 20 mm, 25 mm**, and **50 mm**

* **Applications:** Used in **expansion joints**, **road construction**, **bridges**, **pavements**, and **insulation boards** for both industrial and commercial use.

---

### 📐 **Standard Sizes:**

* **Sheet Size:**

* Standard sheet size: **1220 mm x 2440 mm** (4 ft x 8 ft)

* Custom sizes available on request to meet project-specific needs.

* **Thickness:**

* Available in multiple thicknesses, including **12 mm**, **18 mm**, **20 mm**, **25 mm**, and **50 mm** (25 mm is common for expansion joints).

---

### 📦 **Packaging Configuration:**

#### 🔹 **1. Board Stacking:**

* The DuraBoard sheets are **stacked flat** to prevent any bending or deformation during shipping.

* Each sheet is separated with **kraft paper** or **polyethylene interleaves** to prevent them from sticking together and to reduce friction.

#### 🔹 **2. Wrapping & Protection:**

* The stack of DuraBoard sheets is **wrapped in plastic film** or **shrink-wrapped** to protect the boards from moisture, dirt, and physical damage.

* **Corner protectors** (typically made from cardboard or plastic) may be applied to prevent **edge damage** during transportation.

#### 🔹 **3. Palletization:**

* The wrapped stacks of DuraBoard sheets are placed on **wooden pallets** for easy handling and transport.

* Each pallet typically contains **10 to 25 sheets**, depending on the thickness of the board.

* Pallets are **secured with plastic or steel straps** to ensure that the boards are stable and don’t shift during transit.

* **Shrink-wrapping** is often used to ensure that the pallets remain securely intact during transportation.

#### 🔹 **4. Optional Crating (For Export):**

* For international shipping or high-value projects, the boards may be **crated** in **fumigated wooden crates** to comply with **ISPM-15** standards for export.

* The crate protects the boards from the **elements** and ensures they arrive at their destination **without damage**.

---

### 🚢 **Container Loading (Estimates):**

* **20-foot container:**

* Typically holds **200–300 sheets** of Supreme HD100 DuraBoard (depending on the thickness and size of the boards)

* Approximate total weight: **5,000–8,000 kg**

* **40-foot container:**

* Typically holds **400–600 sheets**

* Approximate total weight: **10,000–16,000 kg**

---

### 🏷️ **Labeling Information:**

* **Product Name:** Supreme HD100 DuraBoard

* **Dimensions:** e.g., 1220 mm x 2440 mm (size) and thickness (e.g., 25 mm)

* **Quantity:** Number of sheets per pallet

* **Weight:** Gross and net weight of the pallet

* **Batch/Lot Number** and **Manufacturing Date**

* **Manufacturer Name** and **Contact Information**

* **Storage and Handling Instructions:** Includes information on safe storage conditions (e.g., keep dry, avoid exposure to extreme temperatures)

* **Country of Origin**

* **Export Marks (if applicable)**

---

### 🧊 **Storage Recommendations:**

* **Storage Location:** Store in a **dry, cool place** away from moisture and **direct sunlight**.

* **Stacking:** Ensure the boards are stored **flat** on pallets to prevent warping or bending. Avoid stacking too high (recommended height is no more than **2 meters**).

* **Protection from Elements:** If storing outdoors, ensure the boards are protected with **tarps** or other covering to keep them dry.

* **UV Protection:** Exposure to **UV rays** over extended periods can degrade the material, so storage indoors or under cover is preferred.

---

### 🚚 **Handling Recommendations:**

* **Careful Handling:** Although the DuraBoard is durable, care should still be taken to avoid **impact damage** to the edges and surface during loading and unloading.

* **Lifting Equipment:** Use appropriate **forklifts** or **pallet jacks** to handle the pallets. Always ensure that the pallets are **securely strapped** before moving.

---

Would you like a **detailed shipping or export specification sheet** for the Supreme HD100 DuraBoard, or do you need any further clarification on the packaging process?

Duraboard HD 100 Expansion Joint Board is a specific type of expansion joint filler board designed for use in construction projects. Here's how it's typically used and its features:

1. **Expansion Joint Filling**: Duraboard HD 100 Expansion Joint Board is primarily used to fill expansion joints in concrete structures. These joints allow for the natural expansion and contraction of concrete slabs due to temperature changes, moisture variations, or settling, preventing cracks and damage to the structure.

2. **Material Composition**: It is typically made from high-density polyethylene (HDPE) foam or similar materials that offer durability, flexibility, and resistance to moisture, chemicals, and weathering.

3. **Installation**: The expansion joint board is cut to size and placed within the joint cavity before concrete pouring. It acts as a buffer between adjacent concrete sections, absorbing movement and stress to maintain the integrity of the joint.

4. **Compatibility**: Duraboard HD 100 Expansion Joint Board is compatible with various construction materials, including concrete, asphalt, and masonry, making it suitable for a wide range of applications such as highways, bridges, parking lots, sidewalks, and industrial flooring.

5. **Benefits**: By effectively filling expansion joints, Duraboard HD 100 helps extend the service life of concrete structures by reducing the risk of cracking, spalling, and other forms of damage. It also helps minimize maintenance requirements and ensures smooth and safe surfaces for vehicles, pedestrians, and other users.

6. **Customization**: The expansion joint boards are available in different thicknesses and widths to accommodate various joint sizes and project requirements. They can also be easily cut or shaped on-site to fit irregular joint configurations.

Overall, Duraboard HD 100 Expansion Joint Board is a reliable solution for managing expansion joints in concrete structures, providing durability, flexibility, and long-lasting performance.